Gravity die casting is widely used for aluminum and other non-ferrous components. Designers often choose this process when they need better dimensional accuracy and mechanical properties than sand casting can offer, but want to avoid the very high tooling cost of high-pressure die casting. By filling a reusable metal mold under gravity instead of high-speed, high-pressure injection, gravity casting can deliver dense, heat-treatable castings with stable quality at medium production volumes. This article explains what gravity casting is, how the process works, where it is most suitable, and how it compares with other casting methods.

What Is Gravity Casting?

Gravity Die Casting (GDC) is a permanent mold casting process in which molten metal is poured from a vessel into a metallic mold (typically made of cast iron or heat-resistant steel). Unlike high-pressure die casting, the mold cavity is filled solely by earth’s gravity. This process is renowned for producing castings with dense internal structures and superior mechanical properties, making it a cornerstone for high-performance industrial components.

How Does Gravity Casting Work?

The process follows a meticulous sequence of steps to ensure the structural integrity of the final part, beginning with the critical preparation of the die:

1. Preheating

Before the casting cycle begins, the metal mold must be heated to a specific temperature, usually between 150°C and 300°C. Preheating prevents the molten metal from freezing prematurely (cold shuts) and ensures that the liquid flows into every intricate detail of the cavity. It also reduces thermal shock, significantly extending the mold’s service life.

2. Coating

A refractory coating or lubricant is sprayed onto the internal surfaces of the mold. This coating serves three critical purposes: protecting the mold from high-temperature erosion, regulating the cooling rate (thermal insulation), and acting as a release agent to ensure the solidified casting can be ejected without sticking.

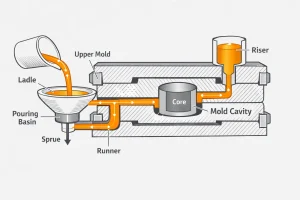

3. Pouring and Filling

The molten metal is poured into the mold through a runner system. The entire filling process relies entirely on the weight of the molten metal. This “natural filling” approach reduces turbulence and splashing, allowing air to escape through vents more effectively than in high-velocity injection processes.

4. Solidification and Feeding

As the metal fills the cavity, it begins to cool and solidify from the mold walls inward. Due to gravity, the molten metal in the risers and gates continues to “feed” the casting, compensating for the natural shrinkage that occurs during cooling. This ensures the final part is dense and free of internal voids.

5. Opening and Ejection

Once the metal has fully solidified and gained enough structural integrity, the mold is opened mechanically. An ejection system (usually hydraulic pins) pushes the casting out of the mold cavity, clearing the die for the next cycle.

6. Cleaning and Inspection

The newly removed casting includes extra material such as gates, runners, and flash. These are removed via cutting, sawing, or grinding. Finally, the part undergoes dimensional inspection, non-destructive testing (such as X-ray), or pressure testing to ensure it meets strict quality standards.

What Are the Materials Suitable for Gravity Die Casting?

GDC is primarily used for non-ferrous metals with moderate melting points to maximize mold longevity:

- Aluminum Alloys: The most widely used material (e.g., A356, AC4C), offering excellent castability and high strength-to-weight ratios.

- Copper Alloys: Such as brass and bronze, used for corrosion-resistant or high-conductivity parts.

- Magnesium Alloys: Ideal for ultra-lightweight applications in the aerospace and automotive sectors.

Advantages of Gravity Casting

- Superior Mechanical Properties: The rapid cooling rate from the metal mold results in a fine grain structure. Parts can undergo T6 heat treatment, achieving much higher strength and hardness than standard pressure die castings.

- High Pressure Tightness: The dense internal structure minimizes porosity, making it ideal for components that must be leak-proof under gas or liquid pressure.

- Long Tooling Life: The mold experiences less pressure and impact than in die casting, leading to lower maintenance costs.

- Complex Internal Geometries: It allows the use of sand cores, enabling the creation of intricate hollow internal shapes.

Limitations of Gravity Casting

- Wall Thickness Constraints: Because it relies on gravity, the minimum wall thickness is typically 3mm or more; thinner sections may not fill completely.

- Slower Production Rate: The cooling and cycle times are longer compared to high-pressure die casting, resulting in lower hourly output.

- Surface Detail: While better than sand casting, the surface finish is slightly less refined than that of high-pressure die casting.

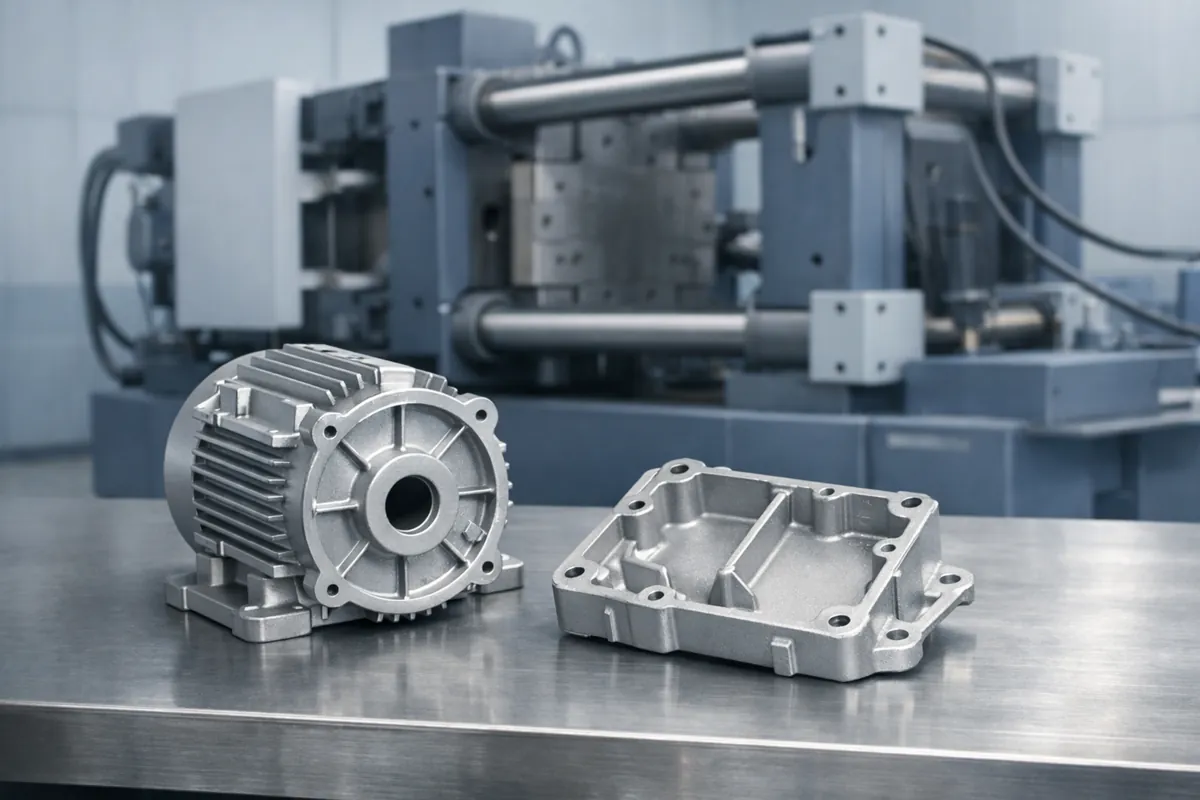

Common Applications of Gravity Casting

- Automotive Industry: Engine cylinder heads, pistons, brake calipers, and steering knuckles.

- Machinery & Energy: Pump impellers, hydraulic valve bodies, high-voltage switchgear housings, and heat sinks.

- High-End Consumer Goods: Professional-grade cookware (cast aluminum pans) and heavy-duty lighting fixtures.

Gravity Casting vs Sand Casting

Compared with sand casting, gravity die casting uses a reusable metal mold instead of expendable sand molds, so it offers higher dimensional accuracy, better surface finish, and more consistent mechanical properties from batch to batch. This makes it easier to control machining allowance and achieve stable, repeatable quality on medium-volume projects. Sand casting, on the other hand, has much lower tooling cost and far greater design freedom, especially for very large castings or extremely complex internal passages. In practice, sand casting is preferred for low volumes, very large parts, or frequently changing designs, while gravity die casting is chosen when you need more stable precision and performance at a reasonable, medium production volume.

Gravity Casting vs Die Casting

Compared with high-pressure die casting, gravity die casting fills the cavity under its own weight rather than by high-speed injection, so metal flow is calmer with less turbulence and a lower risk of gas porosity. This often makes gravity castings more suitable for T6 heat treatment and for components that must be pressure-tight, such as hydraulic or pneumatic housings. Die casting excels in ultra-thin walls, very high annual volumes, and highly complex external shapes, but requires expensive tooling and equipment and is more sensitive to porosity and heat-treat limitations. As a result, die casting is usually selected for high-volume, cost-sensitive housings and covers, while gravity die casting occupies the middle ground where structural integrity, density, and lifecycle cost are more important than maximum production speed.

What Are the Alternatives for Gravity Die Casting?

Gravity die casting is not the only option for non-ferrous castings. Depending on wall thickness, annual volume, cost targets, and internal quality requirements, engineers typically compare it with the following processes:

- Squeeze Casting: sits between casting and forging. High pressure is applied to the metal during solidification, producing extremely dense microstructures and very high mechanical properties. It is suitable for safety-critical components or lightweight designs where a casting is intended to replace a forged part. The process window is narrow, equipment and tooling requirements are demanding, and overall cost is high, so it is typically reserved for high-value parts with very demanding performance requirements.

- Investment Casting: uses wax patterns and ceramic shells to achieve very complex geometries and fine details. It is well suited to small to medium-sized components with intricate shapes, such as blades and small structural parts. Compared with gravity die casting, unit cost is higher and cycle time is slower, so it is usually chosen when geometric complexity and surface detail are more critical than production rate, and when batch sizes are relatively limited.

- Sand Casting: uses expendable sand molds instead of reusable metal dies. Tooling cost is low and design freedom is very high, making it suitable for large parts, extremely complex internal passages, or designs that are still being modified frequently. The trade-off is lower dimensional accuracy, rougher surface finish, and less consistent mechanical properties compared with gravity die casting, which can make it harder to control machining allowance and cosmetic quality.

- High-Pressure Die Casting (HPDC): injects molten metal into the mold cavity at high speed and high pressure. It is ideal for ultra-thin walls, very complex external geometries, and very high annual volumes, where unit cost must be minimized. However, tooling and equipment investment are high, the filling process is highly turbulent, and the risk of gas porosity is greater. Many alloy systems and wall thickness combinations are not suitable for T6 heat treatment or for components that require very high pressure tightness, so HPDC is often used for consumer products and automotive housings where cycle time and piece price are the primary drivers.

- Low-Pressure Casting: uses a low gas pressure to push molten metal from below into the mold cavity. Filling is smoother and more controllable than in gravity casting, enabling excellent consistency and very good internal integrity. It is commonly used for safety-critical structural components such as wheels and suspension parts. Compared with gravity die casting, equipment investment and per-part process cost are higher, and cycle times are generally longer, so it is mainly selected when structural integrity requirements are very high and production volume can justify the additional investment.

Conclusion

Gravity Die Casting is an essential process in modern manufacturing, offering a perfect balance between material performance, internal quality, and investment cost. While it has limits regarding wall thickness and speed, its ability to produce high-density, heat-treatable parts makes it the preferred choice for critical industrial components.

If you are looking for high-quality aluminum casting solutions or have questions about the feasibility of a specific part, feel free to contact our technical team for a detailed consultation. We provide full technical support from design optimization to mold manufacturing!