In an era where lightweighting and structural integrity are paramount, producing high-performance aluminum components with zero defects remains a top priority for engineers. Low Pressure Die Casting (LPDC) has emerged as the definitive solution, offering a unique “bottom-up” filling method that balances the cost-effectiveness of gravity casting with the precision of high-pressure systems. In this article, we explore the mechanics of LPDC, its standout advantages, and why it remains the gold standard for safety-critical manufacturing.

What Is Low Pressure Die Casting (LPDC)?

Low Pressure Die Casting (LPDC) is a metal casting process characterized by the filling of a mold with molten metal under low pressure (typically 0.02 to 0.15 MPa). The metal rises from a pressurized holding furnace into the mold, solidifying under constant pressure to ensure high structural integrity.

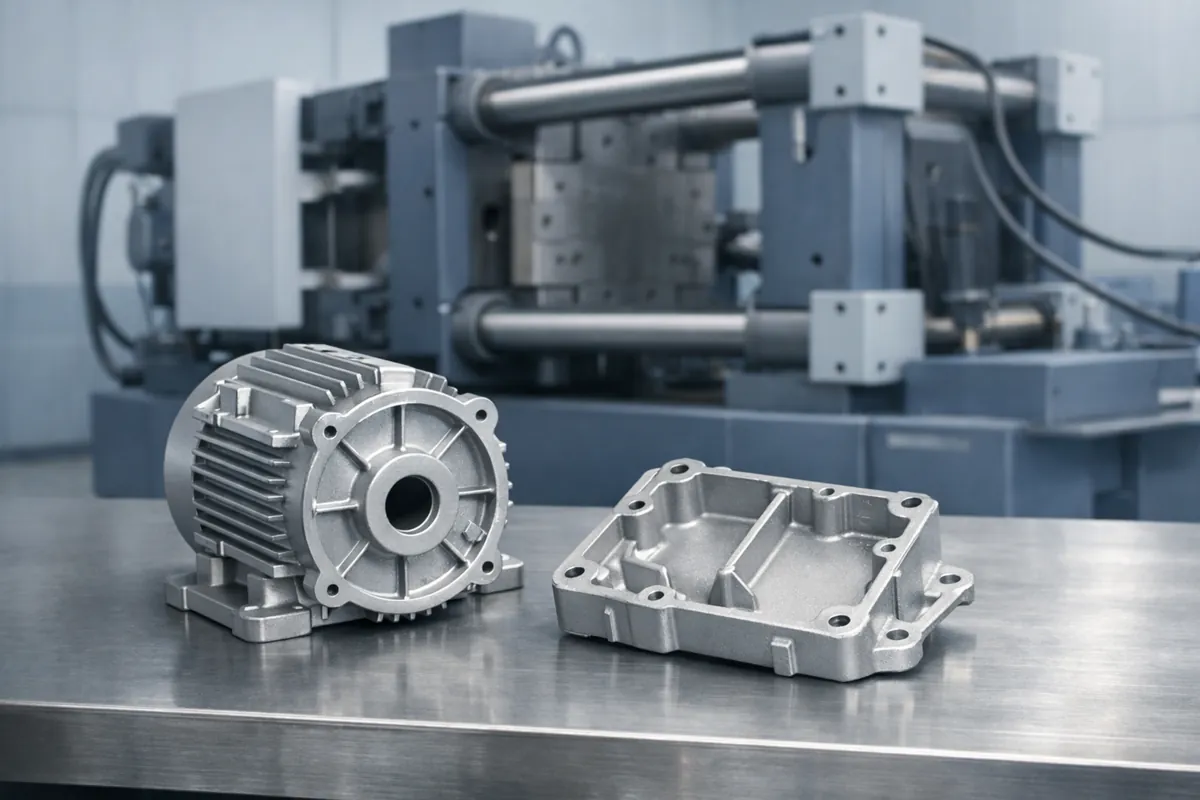

Positioned between gravity casting and high-pressure die casting, LPDC is the preferred method for producing high-quality, high-precision non-ferrous metal parts, such as aluminum alloy wheels, engine cylinder heads, and complex thin-walled structural components.

How Does Low Pressure Die Casting Work?

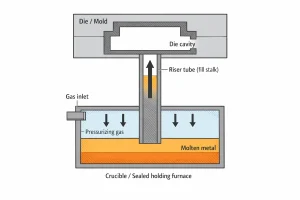

The LPDC process functions similarly to a controlled liquid delivery system. The standard setup consists of a sealed holding furnace, a riser tube (also known as a stalk), and a mold positioned above the furnace.

The Step-by-Step Process:

- Sealing & Pressurization: Dry compressed air or inert gas is introduced into the sealed holding furnace.

- Rising: As the pressure increases, the molten metal is forced up through the riser tube—submerged below the liquid surface—to fill the mold cavity smoothly from the bottom up.

- Filling & Holding: Once the cavity is filled, the pressure is maintained. This constant pressure allows the molten metal in the riser tube to act as a “riser,” feeding the shrinkage of the casting as it cools to ensure a dense internal structure without porosity.

- Solidification & Exhaust: The casting solidifies under pressure. Once solidified, the pressure is released, and the remaining unsolidified metal in the riser tube flows back into the furnace by gravity.

- Ejection: The mold opens, the part is ejected, and the system is ready for the next cycle.

Materials Suitable for Low Pressure Die Casting

Low Pressure Die Casting is primarily utilized for non-ferrous metals, particularly alloys that demand superior internal integrity. Key materials include:

- Aluminum Alloys: The most common material for LPDC, such as A356, A380, and AlSi7Mg. Due to their excellent fluidity and strength-to-weight ratio, they are the standard for automotive wheels and engine parts.

- Magnesium Alloys: For aerospace or high-performance racing components requiring extreme weight reduction, LPDC ensures smooth filling without gas entrapment for highly reactive magnesium.

- Copper Alloys: Including bronze and brass. Because LPDC minimizes oxidation during the process, it is often used for high-performance valve bodies, pump components, and electrical fittings.

- Other Non-Ferrous Metals: In specific industrial sectors, zinc alloys may also be processed via LPDC to achieve superior mechanical properties.

Advantages of Low Pressure Die Casting

LPDC is widely utilized in the automotive and aerospace industries due to several key benefits:

- Superior Material Purity: Since the metal is drawn from beneath the surface, the entry of oxide skins and dross into the mold is prevented, resulting in exceptional internal quality.

- Dense Microstructure: Solidification under pressure provides excellent feeding capabilities, significantly reducing the occurrence of shrinkage cavities and porosity.

- High Material Yield: This process typically requires fewer and smaller gates and risers compared to gravity casting, leading to a metal utilization rate often exceeding 90%.

- Stable Filling: Controllable pressure and velocity ensure a smooth, laminar flow. This minimizes gas entrapment and mold erosion, making it ideal for complex, thin-walled parts.

- Automation-Friendly: The entire process is controlled by precise pressure curves, ensuring high repeatability and reducing dependence on manual labor.

Limitations of Low Pressure Die Casting

While LPDC offers exceptional part quality, it is important to consider certain limitations based on your production requirements:

- Longer Cycle Times: Because the molten metal is injected slowly and must solidify completely under pressure before the cycle ends, the production speed is generally slower than High Pressure Die Casting (HPDC).

- Equipment Maintenance: Components like the riser tube and sealing gaskets are constantly exposed to high-temperature molten metal. This requires regular maintenance and periodic replacement, which can increase operational costs.

- Minimum Wall Thickness Constraints: While LPDC is excellent for medium-to-thick-walled components, it may struggle to fill extremely thin sections (typically under 2-3mm) as effectively as the high-velocity HPDC process.

- Stringent Process Control: The quality of the casting is highly sensitive to fluctuations in air pressure and furnace sealing. Achieving consistent results requires high-precision equipment and strict environmental controls on the shop floor.

Key Applications of Low Pressure Die Casting

LPDC is the preferred choice for components that must endure high stress, require excellent airtightness, and feature complex geometries.

- Automotive Industry: The most prominent sector, utilizing LPDC for aluminum alloy wheels, engine cylinder heads, blocks, suspension brackets, and battery housings for electric vehicles (EVs).

- Aerospace: Critical for structural components, fuel system parts, and magnesium alloy housings where extreme weight-to-strength ratios are required.

- Power & Energy: Used for high-voltage switchgear housings, electrical fittings, and key aluminum connectors in wind energy systems.

- General Industrial: High-end pump bodies, valve housings, impellers, and precision machinery parts that demand superior internal integrity.

Low Pressure Die Casting vs. High Pressure Die Casting

While both processes use pressure, they serve different industrial needs:

| Feature | Low Pressure Die Casting (LPDC) | High Pressure Die Casting (HPDC) |

| Pressure Range | Very Low ($<0.15 \text{ MPa}$) | Very High ($>10 \text{ MPa}$) |

| Filling Velocity | Slow, Smooth Laminar Flow | Rapid, Turbulent Flow |

| Mechanical Properties | Excellent (Supports T6 Heat Treatment) | Moderate (Gas entrapment limits heat treatment) |

| Mold Life | High (Less thermal/physical erosion) | Lower (High-speed impact causes wear) |

| Key Applications | Safety-critical parts (Wheels, Cylinder Heads) | High-volume, complex thin-walled housings |

| Wall Thickness | Suitable for thick to medium walls | Ideal for extremely thin walls |

Conclusion

Low Pressure Die Casting (LPDC) has become the go-to solution for manufacturers seeking high-performance castings and maximum material efficiency. While its cycle time may be slower than high-pressure die casting, its ability to produce safety-critical, structurally sound components makes it irreplaceable in modern manufacturing.

As the global demand for lightweight solutions in the automotive and aerospace sectors continues to grow, the role of LPDC in high-end aluminum and magnesium alloy processing is more vital than ever.

If you are looking for high-quality low-pressure die casting solutions or need a feasibility assessment for your next project, please contact our engineering team for professional technical support and a customized quotation.