Understanding the Hidden Drivers of Casting Costs

When planning a custom metal casting project, many buyers initially focus on material pricing and order quantity. While these are important, they’re just part of the cost equation.

In reality, a number of less-visible factors—ranging from design complexity to secondary processing—can significantly influence the total cost.

Understanding these drivers helps engineering teams make smarter decisions and avoid unexpected overruns.

Material Choice: More Than Just a Price Tag

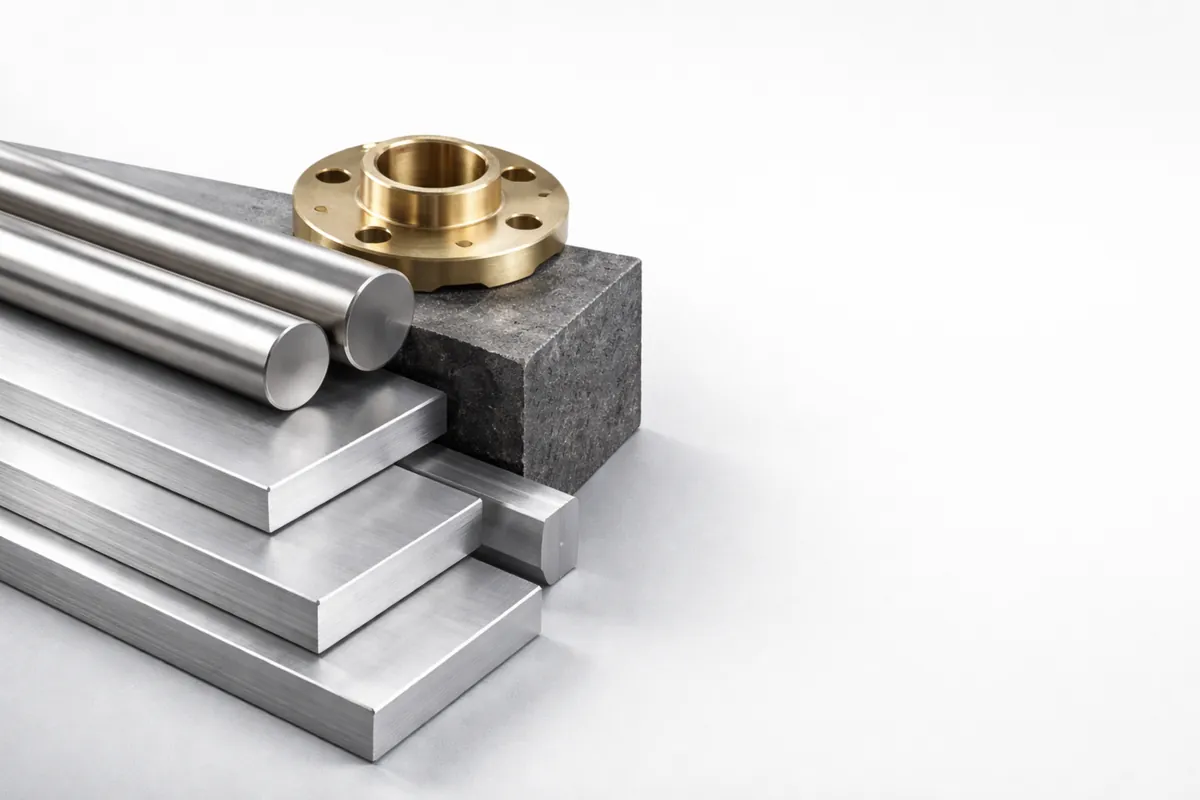

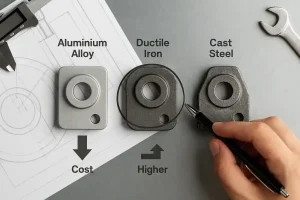

Raw material cost isn’t just about the price per kilogram—it affects casting performance, tooling, machining, and even scrap rate.

For example, ductile iron is generally cheaper than stainless steel, but may lack the corrosion resistance or tensile strength required for certain applications. Aluminum alloys, while lightweight and easy to machine, may demand tighter casting tolerances and better mold control.

his image visually compares common casting materials and their cost impact.

In custom metal casting projects, material choice has a direct impact on both production quality and cost efficiency. Using commonly available alloys can also reduce lead times and improve overall sourcing reliability.

Learn more about the properties and use cases of cast iron in our in-depth guide.

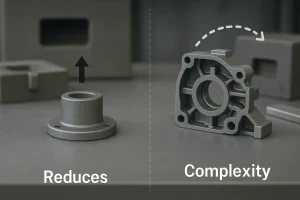

Process Complexity: When Design Drives Cost Up

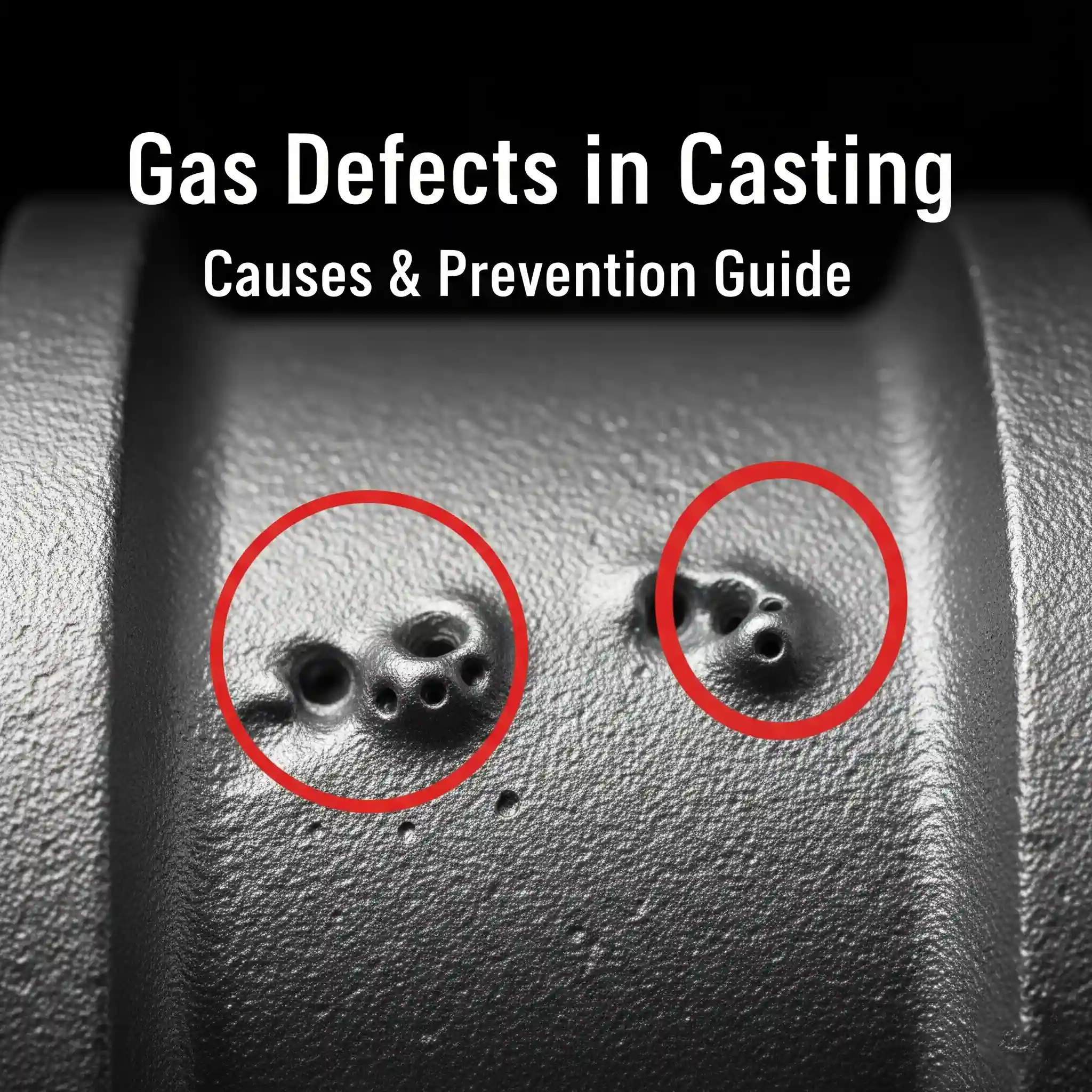

Not all casting processes are created equal. Choosing between sand casting, investment casting, or permanent mold depends not only on technical fit, but also on budget and complexity.

A simple structural part with consistent wall thickness can often be cast using green sand at minimal cost. But when a design includes tight corners, thin sections, or multiple cores, the tooling becomes more sophisticated—and more expensive.

Complexity also affects cycle time and defect rate. Intricate molds take longer to prepare and may increase the risk of porosity, cold shuts, or misruns. For a deeper dive into preventing a common issue like porosity, you can read our guide: [A Practical Guide to Gas Defects in Casting: Causes, Types, and Prevention. In custom metal casting projects, every added geometric challenge tends to push cost upward across multiple stages—from tooling to quality control.

This image compares casting methods with respect to part geometry and production complexity.

Each process has distinct cost implications, as detailed in our comparison of sand casting and die casting.

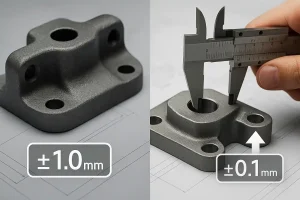

Tolerances and Surface Requirements: Hidden Cost Multipliers

Tight dimensional tolerances and refined surface finishes are often necessary in metal casting projects—but they come at a price.

Achieving close tolerances usually requires post-casting machining, which adds labor time, tooling wear, and fixture costs. Similarly, demanding surface finishes may require additional treatments like grinding, polishing, or coating—each step increasing total cost and production time.

This image shows how tighter dimensional tolerances in casting can increase manufacturing costs.

In many cases, over-specifying tolerances or finishes has little to no impact on function, but significantly drives up cost. For example, specifying a ±0.1 mm tolerance on a non-mating surface could trigger unnecessary secondary operations.

When planning custom castings, it’s essential to match precision levels to actual performance needs. A good casting design minimizes overprocessing without sacrificing part quality.

For common tolerance ranges by material and method, refer to our aluminum casting tolerance guide.

Volume and Batch Size: Why Scale Matters

In metal casting, quantity has a direct influence on unit cost. The same part can cost significantly more per piece in low-volume production compared to a larger run.

This is largely due to how fixed costs—like tooling, setup, and pattern making—are spread across the total order. For small batches, these fixed costs remain high, making the per-part cost disproportionately expensive. In contrast, large production runs allow these expenses to be absorbed more efficiently.

In custom casting projects, understanding your batch size early can help you select the right process. For example, sand casting is typically more economical for short runs, while permanent mold casting becomes viable as volumes increase.

Working closely with your supplier to align expected quantities with the right process can lead to meaningful cost savings without compromising part quality.

Post-Processing and Logistics: The Final Cost Layer

Casting is only part of the journey—many components require further processing before they’re ready for use. These post-casting steps can significantly increase overall project costs.

Common secondary operations include heat treatment, CNC machining, drilling, painting, or surface coating. Each of these adds time, equipment usage, and quality inspection requirements. If not accounted for early, they can lead to budget overruns and delivery delays.

Logistics is another hidden cost, especially in international projects. Factors such as export packaging, shipping method, insurance, and customs clearance all contribute to the final price. Bulky or irregularly shaped castings may require special handling, further increasing freight charges.

When evaluating quotes for custom metal casting, it’s important to clarify what’s included—and what isn’t. A seemingly low unit price may exclude critical post-processing or delivery costs.

Smart Design: The Best Way to Control Cost

One of the most effective ways to manage casting cost is through design optimization. Uniform wall thickness, generous draft angles, and reduced core usage can all simplify manufacturing and reduce material waste.

Engaging with your casting supplier early in the design process often uncovers opportunities to eliminate unnecessary features, consolidate parts, or switch to a more cost-effective alloy—all without compromising function.

Proactive design reviews not only improve castability but often shorten lead time and reduce tooling revisions, making your entire project more efficient.

Plan Ahead, Cast Smarter

Understanding where costs come from is the first step toward controlling them. From material choice to logistics, every decision shapes the total cost of a custom casting project.

If you’re planning a new casting project, contact our engineering team for guidance on cost-effective options tailored to your design, quantity, and delivery needs.