Introduction

In sand casting, creating complex internal geometries often requires more than just a well-designed mold. That’s where core making becomes essential. A core is a pre-formed sand shape inserted into the mold cavity to form internal passages, hollows, or complex undercuts that cannot be achieved through the mold alone. Whether it’s a pump housing with intricate flow channels or an engine block with coolant pathways, cores play a vital role in shaping the internal structure of a casting.

Understanding how cores are made, what types are available, and how to design them properly can significantly affect the quality, cost, and manufacturability of your final part. In this article, we’ll explore the core making process within the context of sand casting and offer practical guidance for engineers and buyers alike.

What Is a Core in Sand Casting?

A sand casting core is typically made of sand mixed with a binder, formed in a separate core box, and placed inside the main mold cavity. Its primary purpose is to shape internal voids that are not accessible by standard pattern equipment. Cores are essential for creating:

-

- Internal cavities in valve bodies or manifolds

-

- Cooling channels in engine components

-

- Hollow sections in pump and compressor housings

Because cores are sacrificial, they are removed after the casting solidifies and is taken out of the mold—either mechanically or by thermal or vibratory methods.

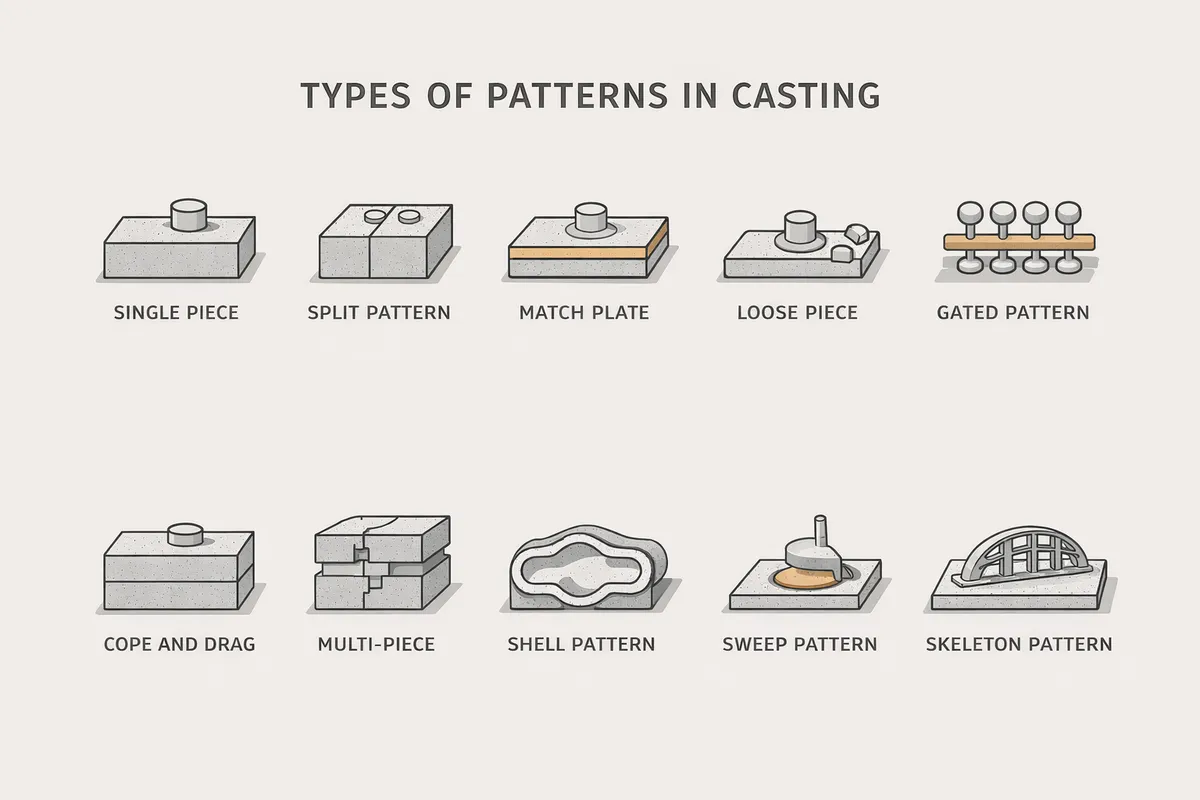

Common Types of Cores

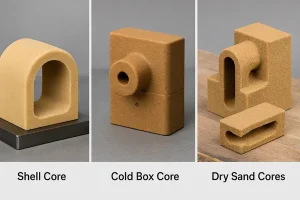

There are several types of cores used in casting, each suited to specific applications based on strength, accuracy, and production speed. Understanding the types of cores in casting helps optimize both design and cost.

-

- Green sand cores

Made from the same sand as the mold, these are low-cost but fragile—suitable for simple shapes.

- Green sand cores

-

- Dry sand cores

Baked cores with better strength and dimensional accuracy; widely used in general applications.

- Dry sand cores

-

- Shell cores

Created by heating resin-coated sand in a shell core machine. These offer excellent surface finish and dimensional control, ideal for high-precision parts.

- Shell cores

-

- Cold box cores

Made using gas-hardened resins at room temperature. These cores offer fast production cycles and high strength.

- Cold box cores

-

- Hot box cores

Cured using heat and a thermosetting resin, providing excellent collapse characteristics after pouring.

- Hot box cores

Each type of core comes with trade-offs in terms of strength, collapsibility, and process complexity.

Visual comparison of common casting core types used in sand casting: solid, hollow, and shell cores

Core Making Process

The core making process involves multiple stages, each affecting the performance of the final casting:

-

- Core box design – Determines the shape and tolerance of the core; must account for draft angles and handling stress.

-

- Sand and binder mixing – Sand is mixed with binders like phenolic urethane, sodium silicate, or furan.

-

- Core shooting or blowing – Sand is injected into the core box under pressure or gravity.

-

- Hardening or curing – Using heat (hot box), chemical gassing (cold box), or baking (dry core), the core gains strength.

-

- Core removal and handling – After curing, cores are removed, trimmed, inspected, and stored until used.

Each step demands quality control to avoid dimensional errors or core shift during mold assembly.

A visual breakdown of each step in the sand casting core making process, from mold setup to hardened core removal.

Design Considerations for Cores

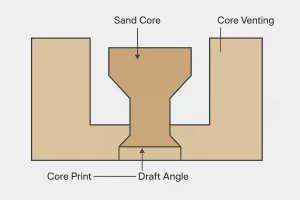

Effective core design in casting helps prevent defects, reduce material use, and simplify core removal. Key design tips include:

-

- Use proper draft angles

Draft allows easy removal from the core box and ensures dimensional accuracy.

- Use proper draft angles

-

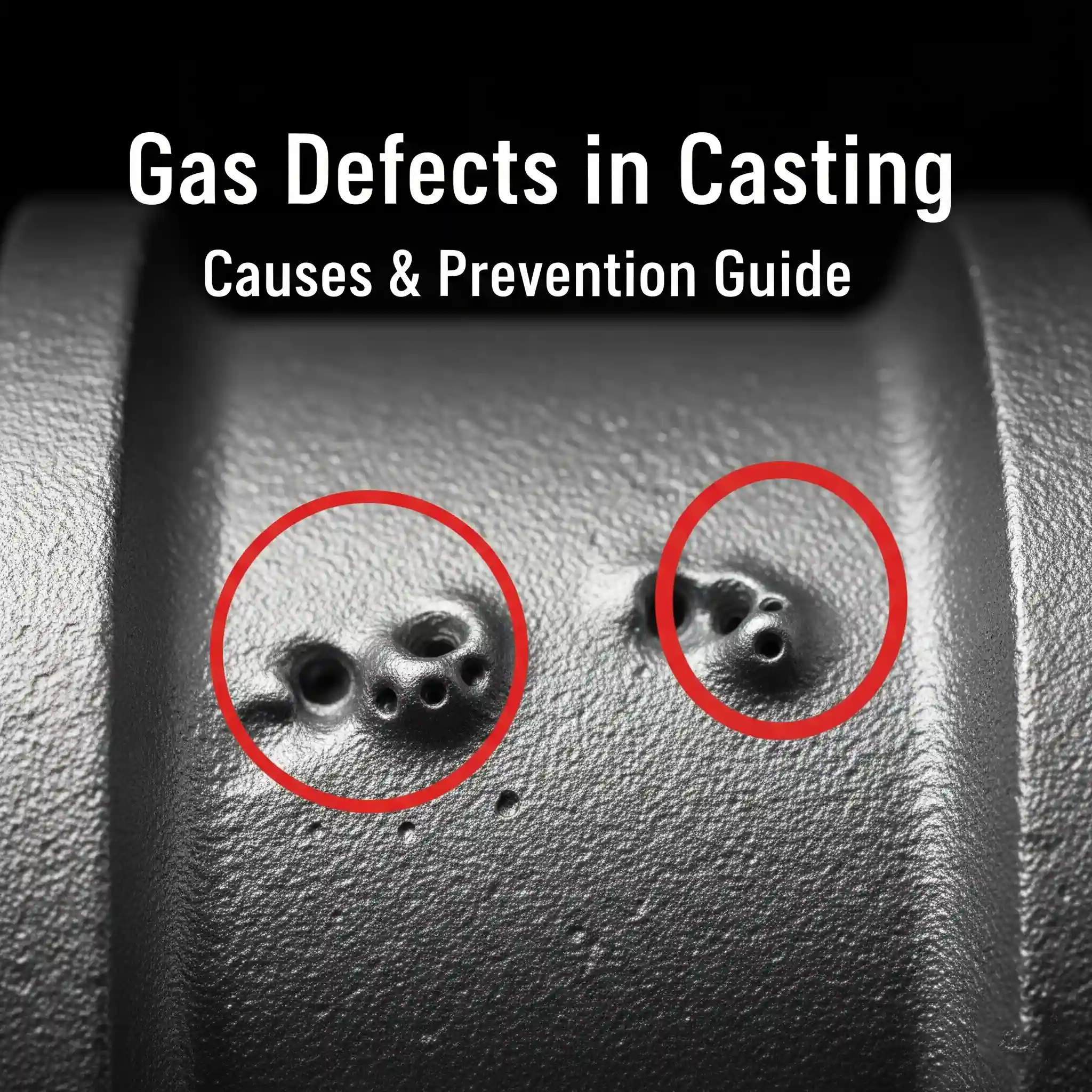

- Include vents

Proper core venting prevents gas buildup, which can cause porosity or blowholes in the final casting.

- Include vents

-

- Integrate core prints

A core print is a feature in the mold that supports and aligns the core. It ensures accurate positioning and prevents movement during pouring.

- Integrate core prints

-

- Balance strength and collapsibility

The core must withstand mold handling but also break away cleanly during shakeout.

- Balance strength and collapsibility

-

- Avoid thin unsupported sections

These can lead to breakage during core removal or metal turbulence during pouring.

- Avoid thin unsupported sections

Good design minimizes rework and scrap, while ensuring reliable and repeatable casting performance.

Diagram showing correct and incorrect core design approaches in sand casting, highlighting key structural support considerations.

Conclusion

Core making is an indispensable part of the sand casting process, enabling the production of complex, high-performance castings. From selecting the right core type to optimizing the core print and venting layout, each design decision directly impacts casting quality, cost, and manufacturability.

By understanding the available technologies—like shell core, cold box core, and core baking methods—foundry engineers and buyers can make informed choices that reduce defects and improve final part consistency.

Want to learn more about casting design and defect prevention?

Check out our articles on Common Casting Defects, How to Make a Sand Cast Mold and How to Design Castings for Sand Molds.