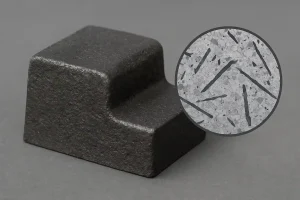

Gray cast iron is an iron-carbon alloy with a relatively high carbon and silicon content. Its name is derived from the unique gray color of its fractured surface, which is caused by the exposure of graphite in its microstructure.

The origin of gray cast iron can be traced back to China around the 5th century BC, where the technology for casting molten iron was first developed. This technology was introduced to Europe around the 15th century and was subsequently advanced and widely applied during the Industrial Revolution in the 18th century.

Gray Cast Iron Material Properties

The performance of gray cast iron is determined by its unique microstructure, giving it several properties that are highly valuable in industrial applications.

1. Damping Capacity

Gray cast iron has excellent damping capacity, which is its most prominent physical characteristic. The flake graphite structure in its interior effectively absorbs and dissipates mechanical vibration energy, demonstrating high damping properties. This feature makes it an ideal choice for manufacturing components that require high stability and low vibration, such as the bases of machine tool beds.

2. Machinability

The material possesses good machinability. This ease of processing comes from the graphite phase within it, which acts as a lubricant during cutting. It effectively reduces cutting resistance and tool wear, and helps to achieve a smooth surface finish. This is a significant cost consideration for components that require extensive post-processing.

3. Wear Resistance

Gray cast iron exhibits good wear resistance under sliding friction conditions. Its microstructure can retain lubricants and form a protective film on the friction surface, effectively preventing direct metal-to-metal contact and wear.

4. Tensile Strength & Ductility

Tensile strength and ductility are weak points for gray cast iron. The flake graphite in its microstructure acts as a stress concentration point, making the material sensitive to tensile and impact loads and prone to brittle fracture. Therefore, these are crucial factors to consider when evaluating applications.

5. Solidification Shrinkage

During the casting process, the volume expansion caused by the precipitation of graphite offsets some of the solidification shrinkage. This results in a low net shrinkage rate, making gray cast iron well-suited for casting complex shapes with strict dimensional requirements.

Density of Gray Cast Iron

The density of gray cast iron is one of its important physical properties, typically influenced by its chemical composition and cooling rate. As different grades of gray cast iron have variations in their microstructure (specifically in graphite content and matrix type), their density will fluctuate within a specific range.

Here are the reference density values for different grades of gray cast iron:

| Gray Cast Iron Grade | Density Range (g/cm³) | Density Range (lb/in³) |

| HT100 (Class 20) | 7.00 – 7.15 | 0.253 – 0.258 |

| HT150 (Class 25) | 7.10 – 7.25 | 0.256 – 0.262 |

| HT200 (Class 30) | 7.20 – 7.35 | 0.260 – 0.266 |

| HT250 (Class 35) | 7.25 – 7.40 | 0.262 – 0.267 |

| HT300 (Class 40) | 7.30 – 7.45 | 0.264 – 0.269 |

Export to Sheets

Note:

Generally, as the grade increases (indicating higher strength and hardness), the density of gray cast iron also tends to increase.

Density can vary slightly depending on the specific chemical composition and casting process parameters.

Gray Cast Iron Microstructure

1. The Core Structure: Graphite Flakes and Metallic Matrix

- Overview: The microstructure of gray cast iron is composed of two primary parts: Graphite Flakes and the Metallic Matrix. These two components are the key determinants of all gray cast iron properties.

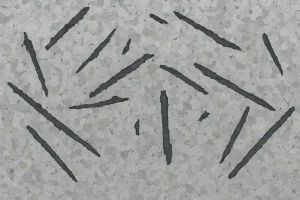

2. Graphite Flakes

- Morphology: Graphite exists in the form of flakes within the metallic matrix, often resembling rose petals or worms in shape. Their size, number, and distribution significantly influence the material’s final performance.

- Impact on Properties:

- Positive Impact: These graphite flakes are what give gray cast iron its exceptional damping capacity and machinability. They act as both internal lubricants and vibration absorbers.

- Negative Impact: The flakes also create stress concentration points within the material, which are responsible for the significantly reduced tensile strength and ductility of gray cast iron.

3. The Metallic Matrix

- Composition: The metallic matrix is the metal phase that holds the graphite flakes. It is typically composed of Ferrite, Pearlite, or a mixture of both.

- Impact on Properties:

- Pearlitic Matrix: If the matrix is predominantly pearlitic, the gray cast iron will have higher strength and hardness, though its machinability may be slightly lower.

- Ferritic Matrix: A predominantly ferritic matrix results in lower hardness and strength, but the material will have better ductility.

- Mixed Matrix: By controlling the cooling rate and chemical composition during the casting process, a mixed pearlitic-ferritic matrix can be achieved to balance the material’s properties.

4. Summary: The Link Between Microstructure and Macroscopic Properties

Concluding Point: The final properties of gray cast iron can be adjusted by controlling the microstructure of both the graphite flakes and the metallic matrix. For example, increasing the number of graphite flakes enhances damping capacity, while increasing the proportion of pearlite improves strength. This is the core principle that allows casting engineers to customize material performance by precisely controlling composition and processing.

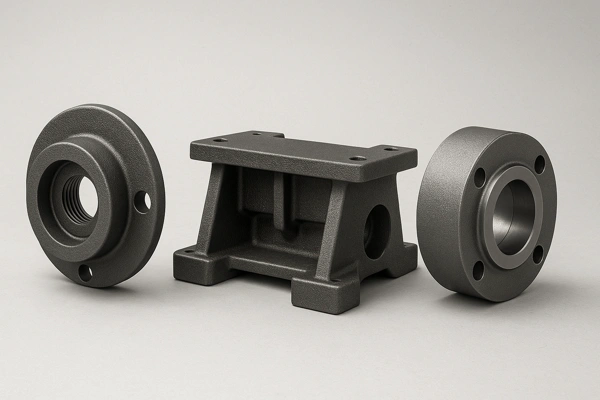

Application of Gray Cast Iron

Thanks to its unique combination of properties—particularly its excellent damping capacity, good machinability, and cost-effectiveness—gray cast iron finds widespread application across multiple industries. Its use is typically concentrated in areas where high strength and impact toughness are not critical, but where stability and wear resistance are highly valued.

1. Machinery and Machine Tool Industry

In the machinery manufacturing sector, gray cast iron is a fundamental material. Key components like machine tool beds, bases, and frames are predominantly made from gray cast iron. This is primarily due to its exceptional damping capacity, which effectively absorbs vibrations generated during the cutting process, thereby ensuring processing accuracy and surface quality. Other components such as gearbox casings and bearing housings are also commonly made from gray cast iron.

2. Automotive Industry

Gray cast iron plays a vital role in the automotive industry. Typical applications include engine blocks and cylinder heads, which utilize the material’s good damping properties to reduce engine noise and vibration. Its wear resistance is also crucial for the reciprocating motion of pistons inside the cylinders. Furthermore, gray cast iron is widely used for brake discs, brake drums, and flywheels, benefiting from its good wear resistance and thermal conductivity.

3. Pipes and Valves Industry

In the pipes and valves industry, gray cast iron is used to manufacture various pipes, fittings, and valve bodies. This is because of its excellent castability, which allows it to be easily cast into complex shapes. Its good corrosion resistance also makes it suitable for transporting media such as water and gas.

4. Agricultural and Construction Machinery

For agricultural and construction machinery, gray cast iron is often used for heavy-duty counterweights. This leverages the material’s high density and low cost. For instance, counterweights for tractors and excavators are largely made of gray cast iron. Other components like transmission housings and gear covers are also commonly produced from this material.

In conclusion, the applications of gray cast iron clearly demonstrate its advantages in specific performance areas. Despite its limited tensile strength, gray cast iron remains an indispensable material in fields where damping, machinability, and cost are critical requirements.