High-Pressure Die Casting (HPDC) holds a central position in modern lightweight manufacturing, particularly in the large-scale production of aluminum, magnesium, and zinc alloys. With the automotive industry’s pursuit of weight reduction and integration, alongside consumer electronics’ demand for ultra-thin profiles, HPDC has become the preferred process for manufacturing automotive structural components, motor housings, and precision electronic enclosures. This article explores the process principles, typical materials, technical advantages, and limitations of HPDC to provide a comprehensive selection guide for your engineering needs.

What Is High-Pressure Die Casting?

High-Pressure Die Casting (HPDC) is a permanent-mold manufacturing process where molten metal is injected into a precision-engineered steel die at extremely high velocities and under significant mechanical pressure.

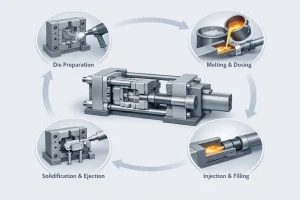

As illustrated in the process diagram below, the core characteristics of this process include high-pressure/high-speed filling, the use of permanent metal molds, and short production cycles. In terms of technical parameters, injection pressures typically range from 1,500 to 25,000 psi, with filling velocities reaching 30–100 m/s. The synchronized action of the injection plunger and clamping force ensures that molten metal fully occupies the die cavity within milliseconds.

History and Development of High-Pressure Die Casting

Die casting technology originated in the mid-19th century within the printing industry, where it was initially used to cast lead type. Subsequent industrial demands pushed the process from simple shape forming toward complex functional components.

In the early 20th century, the explosion of demand for engine parts in the automotive industry brought aluminum die casting into the industrial mainstream. By the late 20th century, the introduction of Computer-Aided Engineering (CAE) and simulation software transformed die casting from an experience-driven craft into a precision-controlled science. Today, the industry is moving toward “Giga-casting,” aiming to integrate dozens of body-in-white components into a single massive aluminum casting.

How High-Pressure Die Casting Works

High-pressure die casting is a highly automated cyclic process where every step requires precise parameter control to ensure the mechanical properties and surface quality of the final part.

1.Die Preparation and Spraying

Before each cycle, the mold surfaces are cleaned and sprayed with a release agent. This lubricant not only facilitates the ejection of the casting but also creates a thermal barrier that regulates die temperature and protects the steel from erosion by the molten metal.

2.Metal Melting and Dosing

The metal is heated to a specified temperature in a controlled furnace. An automated dosing system (such as a robotic ladle or pump) transfers a precise volume of molten metal into the shot sleeve of the die casting machine, which is critical for maintaining part weight consistency.

3.High-Pressure Injection and Filling

The injection plunger moves in two distinct phases: a slow phase to purge air from the shot sleeve, followed by an instantaneous acceleration (milliseconds) to fill the cavity. This high velocity ensures the metal fills thin-walled sections before solidification begins.

4.Solidification, Ejection, and Trimming

The system maintains high pressure (intensification) to compensate for volume shrinkage during cooling. Once solidified, the die opens and ejector pins push the part out. Finally, the runner system and overflows are removed through a trimming die or robotic process.

Differences Between HPDC and LPDC (HPDC vs. LPDC)

When selecting a casting process, understanding the technical boundaries between High-Pressure Die Casting (HPDC) and Low-Pressure Die Casting (LPDC) is vital, as it directly impacts performance and cost.

Regarding pressure and filling velocity, HPDC relies on extreme mechanical pressure and high-speed flow, making it ideal for thin-walled complex parts (1–4 mm). In contrast, LPDC uses low air pressure for a smooth, tranquil fill, which is better suited for thicker-walled, structurally simpler parts.

In terms of internal density and heat treatment, LPDC follows a directional solidification pattern that results in very few internal pores, allowing parts to undergo T6 solution and aging heat treatments. HPDC, due to the turbulence of high-speed filling, tends to entrap air; these micro-pores expand during high-temperature heat treatment, causing surface blistering. Therefore, T6 treatment is generally not recommended for standard HPDC parts.

From an efficiency and application standpoint, HPDC has a very short production cycle and is the top choice for achieving economies of scale. While LPDC offers better airtightness and mechanical strength, it is often reserved for safety-critical components like aluminum wheels, whereas HPDC is used for complex housings and brackets.

Materials Used in High-Pressure Die Casting

Different materials grant die-cast parts unique physical and mechanical characteristics. Selecting the right alloy is the prerequisite for balancing cost, weight, and functionality.

Aluminum Alloys

This is the most common material for HPDC (e.g., ADC12, A380), offering an excellent strength-to-weight ratio, high thermal conductivity, and good corrosion resistance. It is the go-to for automotive and industrial components.

Magnesium Alloys

As the lightest structural metal, magnesium alloys (e.g., AZ91D) provide superior vibration damping and EMI shielding capabilities. They are widely used in high-end consumer electronics frames and automotive interior components.

Zinc Alloys

Zinc alloys (e.g., Zamak 3) feature excellent fluidity and low melting points, allowing for ultra-thin walls (less than 0.5 mm). They are also gentle on tooling, resulting in an exceptionally long die life.

Other Special Alloys

This category includes copper alloys for high-strength wear-resistant parts and specially developed low-silicon aluminum alloys for parts requiring high airtightness or specific surface treatment finishes.

Advantages of High-Pressure Die Casting

- High Production Efficiency: Short cycle times make it the most economical solution for mass production (over 10,000 units per year).

- Thin-Walled Complexity: Capable of forming extremely complex geometries, significantly reducing the need for secondary machining.

- Dimensional Consistency: High repeatability and stable tolerance control make it ideal for automated assembly lines.

Limitations of High-Pressure Die Casting

- Porosity Risks: High-speed filling can cause air entrapment, which limits the part’s weldability and conventional high-temperature heat treatment.

- High Initial Investment: The cost of precision dies and large-scale die-casting machinery is high, making it unsuitable for very low-volume production.

- Wall Thickness Sensitivity: Sensitive to thick sections (hot spots); designs must maintain uniform wall thickness to prevent shrinkage defects.

Applications of High-Pressure Die Casting

Due to its balance of production efficiency and structural complexity, HPDC is used across industries with high precision and capacity requirements.

Automotive

HPDC dominates the automotive sector, used for gearbox housings, motor end caps, steering brackets, alternator housings, and integrated body structures. Its lightweight properties are essential for improving fuel efficiency and EV range.

Consumer Electronics

With its ability to achieve ultra-thin walls and excellent surface finishes, HPDC is widely used in smartphone frames, laptop chassis, tablet internal components, and camera bodies, providing rigid yet lightweight support.

Industrial and Communication Equipment

In the industrial sector, HPDC is used for pump bodies, power tool housings, and heat-sink bases. In telecommunications, it is the core manufacturing process for 5G base station radiators and antenna cavity brackets, where its thermal conductivity ensures equipment stability.

FAQ

Q: Why is this process called “High-Pressure” die casting? A: Unlike gravity casting or low-pressure casting (<0.1 MPa), HPDC applies massive mechanical pressure during the filling stage (typically 10 MPa to over 150 MPa). This high pressure forces the molten metal to overcome resistance and fill intricate gaps instantaneously.

Q: Can HPDC parts achieve waterproof-level airtightness? A: Yes. Although there is a risk of air entrapment, through optimized runner design, vacuum-assisted die casting, or secondary impregnation treatments, HPDC can meet the airtightness requirements of most motor housings and fluid components.

Q: Can die-cast parts be anodized? A: Standard die-casting aluminum (high silicon content) typically appears dark or mottled after anodizing. If anodizing is required, special low-silicon alloys must be used, or alternative finishes like electrophoresis or powder coating should be considered.

Conclusion

High-Pressure Die Casting (HPDC) is the optimal path to balancing “complex geometry, lightweighting, and low unit cost.” While it presents challenges in porosity control and initial investment, its position in modern manufacturing for high-volume, high-consistency production is irreplaceable.

[Upload your 3D drawings now for a fast quote] [Contact our engineers to discuss your process selection]