In the vast world of manufacturing, casting is renowned for its ability to transform molten metal into complex parts. However, casting isn’t a single process; it encompasses a variety of methods, each suited for specific applications. Understanding the unique characteristics of each casting process is key to ensuring part quality, controlling production costs, and optimizing delivery schedules. This article will provide a detailed look at the 10 most common casting processes to help you find the perfect solution for your project.

What is the Casting Process?

Simply put, the casting process is the method of heating a metal until it becomes liquid, then pouring or injecting it into a mold with a specific shape. After the metal cools and solidifies, the mold is removed to reveal a solid part identical to the mold’s interior. The different casting processes are essentially just different ways to achieve this goal, varying in their mold materials, pouring methods, and pressure conditions to meet diverse product needs.

Okay, I will make sure to keep the pros and cons for each casting process. Here is the revised content with the full details, including the advantages and disadvantages for each method.

The Casting Process

The casting process is the method of heating a metal until it becomes liquid, then pouring or injecting it into a mold with a specific shape. After the metal cools and solidifies, the mold is removed to reveal a solid part identical to the mold’s interior. The different casting processes are essentially just different ways to achieve this goal, varying in their mold materials, pouring methods, and pressure conditions to meet diverse product needs.

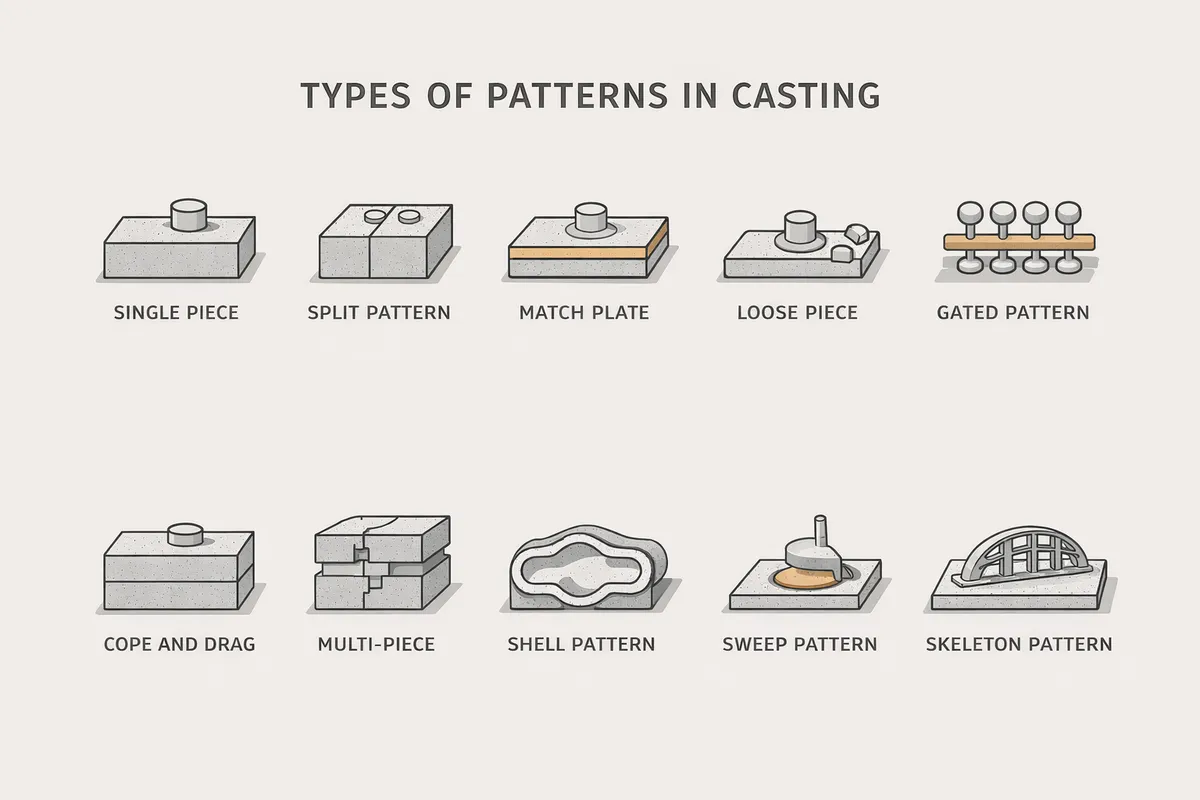

Main Types of Casting Processes

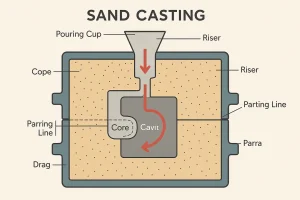

1. Sand Casting

Sand casting uses a reusable pattern (made of wood or metal) to create a negative shape of the part within a sandbox. The mold is made of a mixture of sand, clay, and water or chemical binders. This process is highly versatile, able to cast parts ranging from a few kilograms to several tons, and is compatible with almost any metal, from cast iron to various alloys.

- Pros:

- Low Cost: The mold materials (sand) and equipment are relatively inexpensive.

- High Flexibility: It can be used to cast a wide range of part sizes.

- Wide Material Range: This process can handle almost any metal.

- Cons:

- Rough Surface Finish: Castings have a rough surface texture, which often requires post-processing.

- Low Dimensional Accuracy: Compared to precision casting methods, sand casting has wider dimensional tolerances.

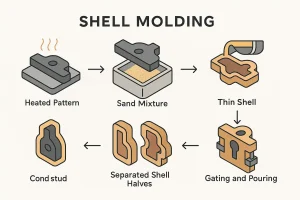

2. Shell Molding

Shell molding uses a resin binder to create a thin, rigid shell mold from sand. The process begins by heating a metal pattern and applying a mixture of sand and thermosetting resin. The resulting shell mold is denser and more stable than a regular sand mold, leading to a better surface finish and higher dimensional accuracy.

- Pros:

- High Production Efficiency: The process can be automated, and the cycle time is short.

- Good Casting Quality: The denser mold results in a better surface finish and higher dimensional accuracy than regular sand casting.

- Reusable Molds: The molds can be used multiple times, lowering the per-part cost.

- Cons:

- Higher Material Cost: The resin binder is more expensive than regular sand.

- Not for Large Parts: The mold size is limited by the equipment, making it unsuitable for casting extremely large parts.

3. Investment Casting

Investment casting is a process born for extreme precision. It first creates a detailed wax pattern, which is then coated with a ceramic slurry to form a rigid shell. This method is capable of producing incredibly complex shapes with very high dimensional accuracy and an excellent surface finish, often eliminating the need for subsequent machining.

- Pros:

- Extremely High Dimensional Accuracy: It can achieve very tight tolerances.

- Excellent Surface Finish: The castings have a very smooth surface.

- Complex Shapes: It can easily produce complex internal and external geometries.

- Cons:

- High Cost: The molds and materials (wax, ceramic slurry) are expensive, and the process involves many steps.

- Long Production Cycle: The entire process, from pattern making to final casting, is time-consuming.

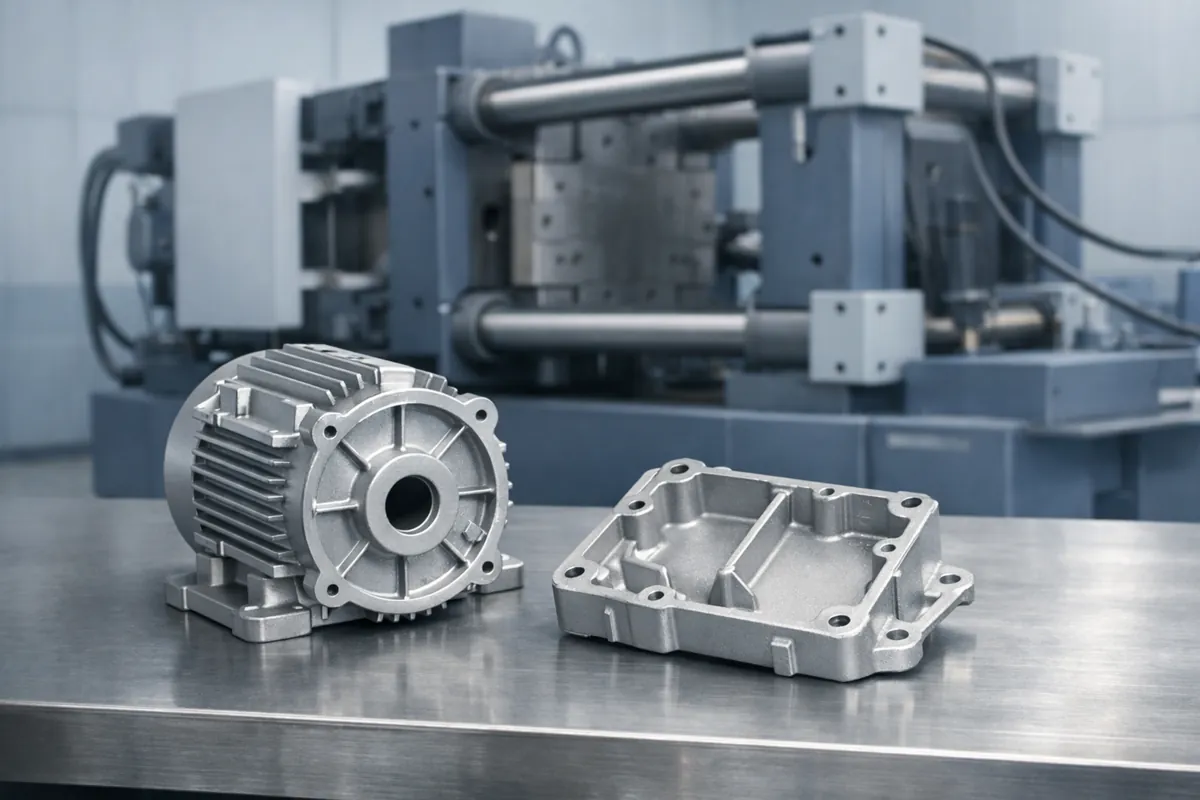

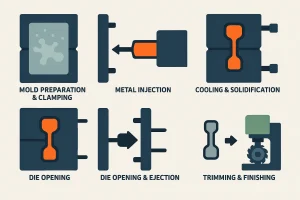

4. Die Casting

Die casting is a process built for mass production. It involves injecting molten metal at high speed and pressure into a precise, reusable steel mold, known as a die. The high pressure ensures the metal fills even the most intricate details, creating a dense internal structure with no air pockets.

- Pros:

- Extremely High Production Efficiency: The cycle time is very short.

- High Part Strength: The high-pressure fill creates a dense internal structure, resulting in stronger parts.

- Suitable for High Volume: The per-part cost drops significantly with increased volume.

- Cons:

- Extremely High Mold Cost: The design and manufacturing of a precise steel mold require a huge initial investment.

- Not for Small Batches: The high mold cost cannot be amortized if the production volume is low.

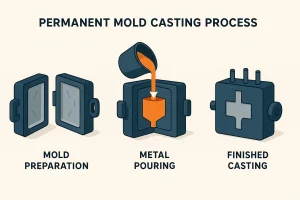

5. Permanent Mold Casting

Permanent mold casting uses a reusable metal mold, with molten metal filling the cavity under gravity or low pressure. Castings from this process have a dense internal structure with good mechanical properties and a better surface finish than sand castings.

- Pros:

- Good Casting Quality: Castings have a dense internal structure with no pores.

- Higher Production Efficiency: Molds can be used repeatedly, and cycle times are faster than in sand casting.

- High Dimensional Accuracy: Castings have tight tolerances and a good surface finish.

- Cons:

- High Mold Cost: The manufacturing cost for metal molds is high.

- Not for Complex Shapes: Molds are typically made in two halves, making it difficult to create overly complex geometries.

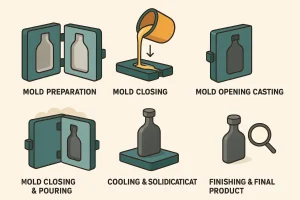

6. Gravity Casting

Gravity casting is a method that uses the molten metal’s own weight to flow into the mold cavity, typically in a metal mold. The process is relatively simple and requires less complex equipment than die casting.

- Pros:

- Simple Process: The operation is relatively straightforward, with low equipment requirements.

- Stable Casting Quality: Due to gravity filling, the castings have fewer internal defects and more stable quality.

- Lower Cost: The upfront investment is much lower than for die casting.

- Cons:

- Long Production Cycle: The natural cooling speed is slower, leading to lower production efficiency.

- Not for Thin-Walled Parts: The limited fluidity of the molten metal makes it difficult to fill complex, thin-walled structures.

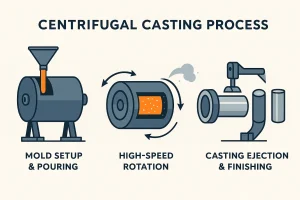

7. Centrifugal Casting

Centrifugal casting uses rotational force to throw liquid metal against the inner wall of a mold. The mold spins at high speed as the molten metal is poured, and the centrifugal force pushes the metal to the outer wall, where it solidifies.

- Pros:

- Dense Internal Structure: The centrifugal force eliminates shrinkage defects and pores.

- No Risers: It doesn’t require complex gating and riser systems, which improves material utilization.

- High Casting Quality: Impurities and lighter materials are pushed to the inner wall and are easy to remove.

- Cons:

- Limited Shapes: Only suitable for manufacturing cylindrical or tubular parts.

- High Equipment Cost: Specialized centrifugal casting equipment requires a large investment.

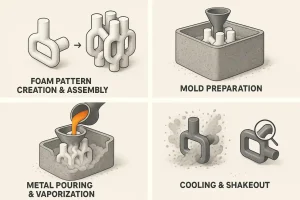

8. Lost Foam Casting

Lost foam casting uses a pattern made of expanded polystyrene (EPS) foam. When molten metal is poured directly onto the pattern, the heat vaporizes the foam, and the metal fills the space left behind. This “vaporization” process allows for near-net-shape casting, reducing the need for post-machining.

- Pros:

- Near-Net Shape: The casting perfectly matches the foam pattern, reducing the need for post-machining.

- One-Piece Casting: Multiple parts can be integrated into a single foam pattern and cast as one piece.

- Simplified Process: There is no need for mold parting lines, simplifying the process.

- Cons:

- Requires High Pattern Accuracy: The foam pattern must be extremely precise, or the final casting quality will be affected.

- Produces Fumes: The foam vaporization process creates toxic fumes, requiring a good ventilation system.

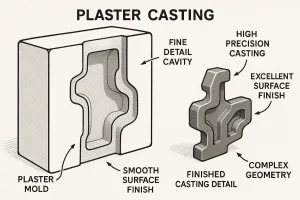

9. Plaster Casting

Plaster casting uses gypsum-based plaster as the mold material. A liquid plaster slurry is poured around a pattern, and after it hardens, the mold is separated and the pattern is removed. Due to the fine texture of the plaster, this process can achieve very high precision and capture extremely fine details.

- Pros:

- High Surface Finish: The castings have a very smooth surface and can capture very fine details.

- High Dimensional Accuracy: The mold precisely replicates the pattern details, resulting in tight tolerances.

- Suitable for Complex Shapes: The plaster’s fluidity allows it to fill complex mold cavities.

- Cons:

- Only for Low-Melting-Point Metals: Plaster molds cannot withstand high temperatures, limiting their use to aluminum, zinc, and other alloys.

- Poor Mold Permeability: It can lead to gas porosity if not properly handled.

10. Continuous Casting

Continuous casting is a special process that continuously produces cast parts of a specific cross-section, rather than individual pieces. Molten metal is continuously poured into a water-cooled mold (crystallizer), and as the metal solidifies, it is continuously withdrawn from the bottom.

- Pros:

- Extremely High Production Efficiency: The process is highly automated and can produce continuously.

- High Material Utilization: Castings do not require risers, so there is less material waste.

- Good Casting Quality: The uniform cooling speed results in a dense and stable casting structure.

- Cons:

- Limited Shapes: It is restricted to producing base materials with a specific cross-section.

- Huge Equipment Investment: It requires a large and complex production line, with very high upfront costs.

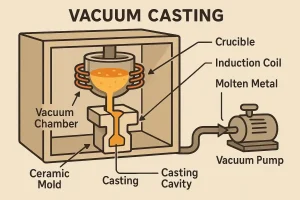

11. Vacuum Casting

Vacuum casting is a specialized method that involves evacuating air from the mold cavity during the casting process. By creating a negative pressure environment, the molten metal is drawn into the mold, ensuring it perfectly fills every detail, including complex and intricate sections, without resistance from trapped air.

Pros:

- High Casting Quality: The vacuum effectively eliminates gas porosity and trapped air, resulting in a dense internal structure.

- Excellent Detail Reproduction: The negative pressure ensures the metal reaches all parts of the mold, accurately reproducing fine details from the pattern.

- Superior Surface Finish: The castings have a very smooth surface, often reducing the need for post-machining.

Cons:

- High Equipment Cost: It requires specialized vacuum equipment, leading to a higher initial investment.

- Lower Production Efficiency: The process is relatively slow and not suitable for high-volume, rapid production.

Conclusion

Each casting process is a testament to human ingenuity, providing a perfect solution for specific industrial needs. Understanding the characteristics of these processes is key to making informed decisions in engineering design and manufacturing. Ultimately, the choice should be based on a comprehensive analysis of the part’s design, material requirements, and production budget, ensuring the chosen process maximizes your project’s goals.

Need help choosing the right casting process for your project? Contact our experts today for a free consultation and let us help you find the optimal manufacturing solution.