Introduction

Dans le monde complexe du moulage de précision, les défauts de gaz dans les pièces moulées constituent un problème courant et difficile. Ces minuscules défauts cachés n'affectent pas seulement l'apparence d'une pièce moulée, mais peuvent également avoir un impact important sur ses propriétés mécaniques et sa fiabilité, entraînant en fin de compte des rebuts et des retouches coûteux.

Comprendre les causes des défauts de gaz et maîtriser des méthodes de prévention efficaces sont des compétences essentielles pour tout ingénieur en fonderie et professionnel du contrôle de la qualité. Ce guide est une ressource pratique qui vous aidera à mieux comprendre la définition et les causes des défauts de gaz et à utiliser des méthodes scientifiques pour les éliminer.

Que sont les défauts de gaz et les défauts de porosité dans la coulée ?

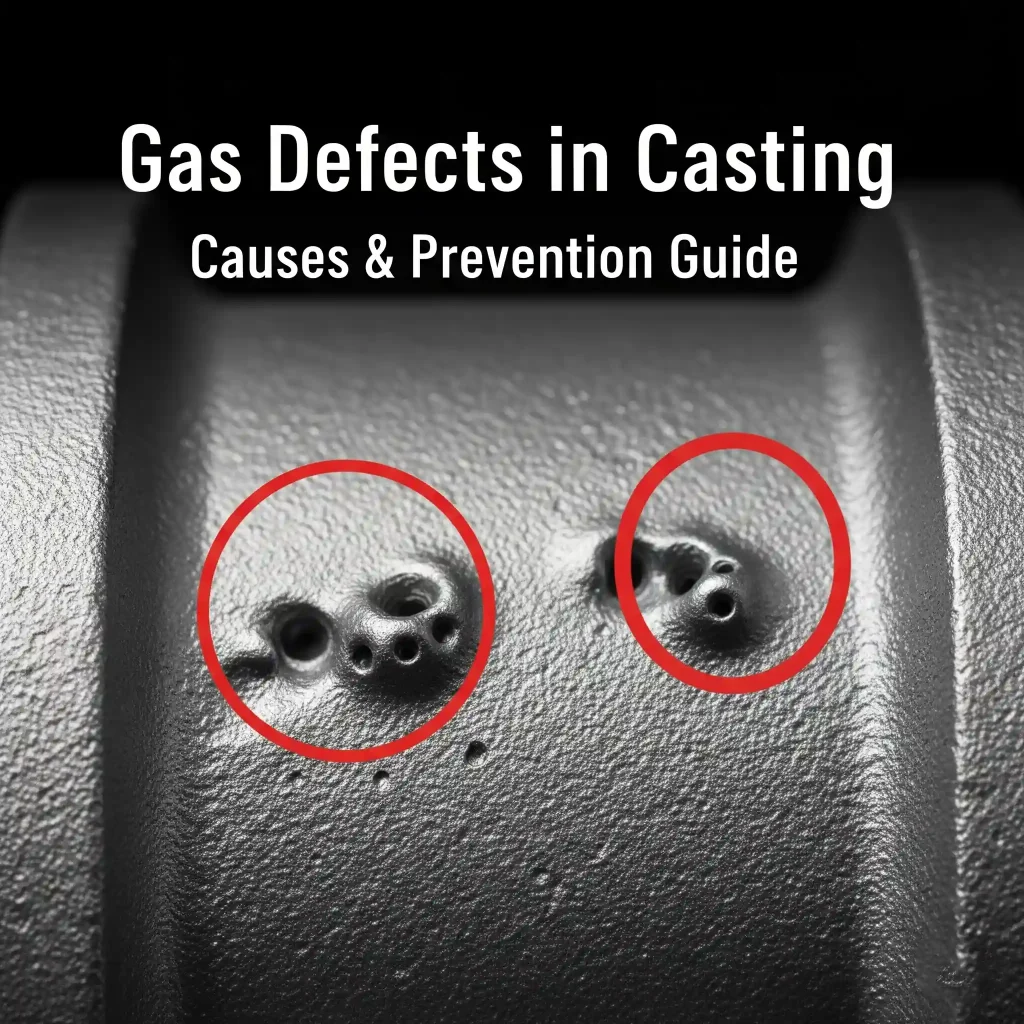

Les défauts de gaz dans la coulée sont généralement définis comme des vides qui se forment à l'intérieur du métal en cours de solidification ou à sa surface en raison de l'impossibilité pour divers gaz de s'échapper. Ces défauts, y compris les défauts de porosité courants en fonderie, peuvent être divisés en plusieurs types principaux en fonction de leur forme et de leur emplacement :

Porosité Il s'agit du type de défaut de gaz le plus courant, souvent appelé défaut de porosité. La porosité se présente généralement sous la forme de cavités sphériques, elliptiques ou irrégulières à l'intérieur ou à la surface de la pièce moulée. Elles peuvent être isolées ou se présenter sous la forme d'un amas en forme de nid d'abeille.

Trous d'épingle Similaires à la porosité mais beaucoup plus petits, les trous d'épingle sont de minuscules vides, généralement d'un diamètre inférieur à 2 mm, qui apparaissent souvent en grappes sur ou juste sous la surface de la pièce moulée.

Trous d'air Il s'agit de cavités plus grandes aux parois lisses, généralement situées sur le dessus ou les côtés de la pièce moulée. Elles se forment généralement lorsque du gaz est piégé dans la cavité du moule.

Causes courantes des défauts de gaz

Pour prévenir efficacement les défauts de gaz et les défauts de porosité connexes, il est essentiel de comprendre d'abord leurs causes profondes. La formation de pores dans une pièce moulée n'est pas due à un seul facteur, mais résulte de l'interaction de plusieurs éléments. Ces causes peuvent être classées dans les catégories suivantes :

Questions relatives au métal en fusion

-

Excès de gaz dissous : Le métal en fusion peut absorber des gaz, en particulier de l'hydrogène, à des températures élevées. Lorsque le métal se refroidit et se solidifie, la solubilité du gaz diminue et l'excès de gaz forme des pores.

-

Humidité et huile dans les matériaux : Si les matières premières ou la ferraille refondue contiennent de l'humidité, de l'huile ou de la rouille, ces substances se décomposent pendant le processus de fusion et produisent du gaz.

Moule à sable et problèmes de noyaux

-

Mauvaise perméabilité des moules à sable : La perméabilité du moule de sable est essentielle pour que les gaz puissent s'échapper. Si les grains de sable sont trop fins, si la teneur en argile est trop élevée ou si le compactage est excessif, la perméabilité peut être insuffisante, ce qui empêche les gaz de s'échapper facilement.

-

Humidité et liants dans les carottes : L'humidité ou les liants organiques présents dans le noyau peuvent générer une grande quantité de gaz à haute température. Si ces gaz ne disposent pas d'une voie d'évacuation adéquate, ils seront piégés à l'intérieur de la pièce moulée.

Questions relatives au processus de déversement et de coulée

-

Système de fermeture inadéquat : Un système de fermeture mal conçu peut provoquer des turbulences dans le métal en fusion, entraînant un piégeage de l'air. De même, des évents ou des colonnes montantes mal placés peuvent empêcher le gaz de s'échapper.

-

Température de coulée excessivement élevée : Une température de coulée élevée augmente la teneur en gaz du métal en fusion et prolonge le temps de solidification, créant ainsi des conditions propices à la formation de gaz.

Méthodes efficaces de prévention des défauts de gaz

Heureusement, les défauts de gaz ne sont pas inévitables. Grâce à un contrôle complet des matériaux, de l'équipement et des processus, il est possible de réduire considérablement leur fréquence.

Contrôle et préparation des matériaux

-

Traitement avant fusion : Sécher soigneusement tous les déchets refondus et les matières premières pour éliminer l'humidité et l'huile.

-

Traitement de dégazage : Dégazer le métal en fusion avant de le couler, par exemple en le purgeant avec un gaz inerte (tel que l'argon).

-

Contrôle de la température de coulée : Contrôler strictement la température de coulée dans la fourchette recommandée pour éviter toute surchauffe.

Conception de moules et de noyaux en sable

-

Améliorer la perméabilité : Utilisez du sable à grains plus grossiers et plus perméable, et contrôlez la densité de compactage.

-

Créer des canaux d'aération : Concevoir des évents et des élévateurs raisonnables dans la cavité du moule et dans le noyau afin de permettre aux gaz de s'échapper en douceur. Pour en savoir plus sur la façon dont le noyautage affecte la qualité du moulage, vous pouvez lire notre article détaillé, Fabrication de noyaux dans la coulée en sable : Types, procédés et conseils de conception.

Optimisation du système et du processus de traitement des vannes

-

Optimiser le système de portes : Concevoir un système d'obturation et des glissières appropriés pour que le métal en fusion s'écoule en douceur dans la cavité du moule, en réduisant les turbulences.

-

Contrôle de la vitesse de versement : Maintenir une vitesse de versement stable afin d'éviter un débit irrégulier qui pourrait entraîner l'emprisonnement de l'air.

Résumé et recommandations

Grâce à un contrôle de qualité complet, la formation de défauts de gaz, en particulier de défauts de porosité, peut être efficacement évitée. Chaque étape est cruciale, de la préparation de la pré-fusion à la conception du moule et à l'opération de coulée finale.

La prévention de ces défauts n'est pas seulement une question de qualité des produits, mais aussi de rentabilité. Pour comprendre l'impact économique, consultez notre guide sur les Les 5 principaux facteurs de coût dans les projets de moulage de métaux sur mesure.

Nous vous recommandons de vous référer à ce guide et de l'ajuster en fonction de vos conditions de coulée spécifiques. Si vous rencontrez des problèmes difficiles liés aux défauts de gaz dans votre production, notre équipe d'ingénieurs professionnels en fonderie est prête à vous fournir une assistance technique et des solutions.