Annealing is one of the most fundamental heat treatment processes in metallurgy. It is designed to improve ductility, reduce internal stresses, and refine the microstructure of metals such as cast iron, steel, aluminum, and copper alloys. By heating a metal to a specific temperature, holding it for a controlled duration, and then cooling it slowly—usually in the furnace—the atomic structure of the metal reorganizes into a more stable and uniform form.

What Is Annealing

In simple terms, annealing is a controlled heating and cooling cycle applied to metallic materials to alter their physical and mechanical properties without changing their shape. The primary goal is to soften the metal and restore its workability after it has been hardened or distorted during processes such as casting, forging, or machining.

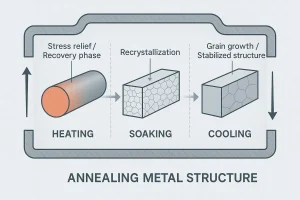

During annealing, three microstructural transformations occur:

- Recovery: Dislocations and internal stresses generated during deformation are relieved.

- Recrystallization: New, strain-free grains form, replacing the deformed structure.

- Grain Growth: At higher temperatures or prolonged holding times, grains enlarge to a stable size.

The result is a material with improved ductility, dimensional stability, and machinability.

Cross-section view illustrating how metal grains transform during the annealing process.

How the Annealing Process Works

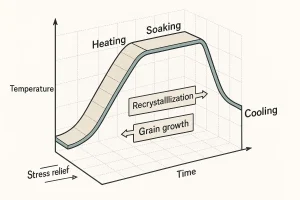

Annealing proceeds through a controlled three-stage thermal cycle. Rather than treating these as isolated steps, it helps to see how each stage prepares the next: heating establishes a uniform temperature field, soaking completes the microstructural changes, and slow cooling locks those changes in without re-introducing stress.

1. Heating stage

In the heating stage, the component is brought up to temperature at a measured rate so that the surface and core rise together without large gradients. For ferrous alloys this usually means targeting 500–900 °C, with heavier castings ramped more slowly to prevent thermal shock or distortion. Proper fixturing keeps load paths balanced, and an inert or reducing furnace atmosphere limits oxidation or decarburization so the surface remains clean for later machining. Temperature is verified with control and load thermocouples so that the entire part—not just the furnace air—reaches the intended setpoint.

2. Soaking stage

Once the section has equalized, the soak allows the metallurgical work to happen. In steels, recovery progresses to recrystallization and produces new, strain-free grains; in cast irons the graphite morphology remains but the matrix can shift toward a softer state that cuts more cleanly. A practical rule is to hold long enough for the thickest ruling section to stabilize—often a base of 30–60 minutes plus additional time with section thickness—while monitoring thermocouples to confirm the whole load is truly at temperature. This stage sets the foundation for stable mechanical properties and predictable machinability.

3. Cooling stage

Cooling then fixes the structure achieved at soak without re-introducing gradients or residual stress. Furnace cooling is preferred when maximum softness and dimensional stability are required, guiding the part slowly through critical ranges to avoid fresh transformations that would harden the matrix. For cast irons in particular, a deliberate, slow cool prevents thermal cracking and avoids re-formation of white-iron patches in thin sections. Parts are typically unloaded below roughly 200 °C and checked on master datums to confirm that the anneal has delivered both microstructural and dimensional stability.

emperature–time curve illustrating the three stages of the annealing process.

Types of Annealing

Different annealing modes exist because production goals differ: sometimes you need the softest possible matrix for machining, sometimes you only need stress removed, and sometimes you must homogenize chemistry before any finishing. Thinking about what outcome you need next will point you to the right subtype.

1. Full annealing

Full annealing is chosen when the priority is maximum softness and a uniform ferrite/pearlite matrix in steels. The workpiece is heated above Ac₃, held long enough for transformation to complete, and then allowed to cool in the furnace so that hardness falls and machinability improves. This is common for forgings, cast-steel housings, and heavy sections that will see significant rough-machining afterward.

2. Process annealing

When parts are only work-hardened from forming and you simply need ductility back for the next pass, process annealing is sufficient. It is carried out below Ac₁ so that recrystallization is limited, time at temperature is modest, and throughput stays high. The result is easier forming without the full softening—or time cost—of a complete anneal.

3. Spheroidizing annealing

High-carbon and tool steels respond best to spheroidizing when the next step is heavy cutting or cold forming. By holding around (or cycling near) Ac₁, lamellar carbides break up into discrete spheroids that reduce cutting forces and improve surface finish. The trade-off is a longer cycle and lower interim hardness, which is usually followed by a hardening and tempering schedule.

4. Stress-relief annealing

If geometry is already near-net and properties are acceptable, but residual stress from casting, welding, or rough machining is a concern, stress-relief annealing is the minimal, targeted option. At temperatures well below the critical range, it relaxes locked-in strain without materially changing the microstructure or hardness. This is the typical stabilization step before precision machining or dimensional inspection.

5. Diffusion (homogenization) annealing

When segregation from solidification is the limiting factor—common in thick alloy castings—diffusion annealing is used first. The component is brought to a high homogenizing temperature for an extended hold so that chemistry evens out across the section. Because this can coarsen grains, it is often followed by a normalizing or full-anneal step to reset the matrix before machining.

6. Recrystallization annealing (non-ferrous)

Aluminum, copper, and brass alloys that have been cold-worked regain ductility through recrystallization annealing. At comparatively low temperatures and short holds, new, strain-free grains form without the risks associated with higher ferrous temperatures. The result is cleaner bends, reduced spring-back, and more predictable forming behavior on the next operation.

Annealing of Cast Iron

Cast iron behaves differently during annealing due to its carbon content and graphite structure:

- Gray Iron: 850–900 °C to relieve stresses and improve machinability.

- Ductile Iron (Nodular Cast Iron): 500–900 °C for stress relief or full annealing to improve elongation.

- White Iron: 850–950 °C to convert cementite into ferrite and graphite, forming malleable iron.

- ADI (Austempered Ductile Iron): Controlled annealing to prepare for re-austempering.

Materials Commonly Annealed

| Material | Typical Temperature (°C) | Purpose |

|---|---|---|

| Carbon Steel | 700–900 | Soften and refine grain |

| Stainless Steel | 1000–1100 | Relieve stress, restore corrosion resistance |

| Gray Cast Iron | 850–900 | Reduce stress, improve machinability |

| Ductile Iron | 500–900 | Stress relief or full softening |

| Aluminum Alloys | 300–400 | Increase ductility |

| Copper Alloys | 250–500 | Remove work hardening |

Advantages of Annealing

- Improves ductility and toughness

- Enhances machinability and dimensional stability

- Relieves internal stresses from casting or forming

- Reduces hardness for easier processing

- Homogenizes microstructure and refines grains

- Restores corrosion resistance in certain alloys

Limitations and Considerations

- Time-consuming process with slow cooling required

- Possible grain coarsening if overheated

- Higher energy cost

- Risk of oxidation or scaling in open-air furnaces

- Requires precise temperature control to avoid phase issues

Applications in Modern Foundries and Manufacturing

Annealing is indispensable in both foundry and post-casting operations. In modern ductile iron or steel foundries, it is used to:

- Remove residual stresses before machining or finishing

- Prepare parts for hardening or carburizing

- Restore toughness in heat-affected weld zones

- Convert white iron to malleable iron for automotive and pipe fittings

- Improve dimensional accuracy of complex castings

Conclusion

Annealing remains one of the most effective and widely used heat treatments for metals. Whether in foundries producing ductile iron castings or machining shops preparing workpieces for finishing, the controlled heating and slow cooling process ensures metals achieve the right balance between strength and ductility.

Request a quote or talk with our foundry engineers today to learn how custom annealing and heat-treatment optimization can enhance your casting performance and stability.

Frequently Asked Questions about Annealing

1. Why is annealing applied after casting?

After casting, metals contain internal stresses and uneven microstructures. Annealing helps relieve these stresses, stabilize dimensions, and improve machinability before machining or surface finishing.

2. Can annealing be performed more than once?

Yes. Components can be re-annealed if they have undergone additional forming, machining, or welding operations that reintroduce stress or strain into the material.

3. How does furnace atmosphere affect annealing quality?

Atmosphere control is critical. An oxidizing or contaminated furnace can cause scaling or decarburization. In foundries, inert or reducing atmospheres such as nitrogen or hydrogen blends are often used for clean surface results.

4. What are common problems during annealing?

Typical issues include uneven heating, oxidation, grain coarsening, or incomplete stress relief. These are prevented through proper temperature control, adequate soaking time, and slow, uniform cooling.