Sand casting is an ancient and widely used metal-forming technique, but even experienced foundry workers face various challenges. Casting defects are among the most frustrating issues, as they can compromise a product’s aesthetic appeal, structural integrity, and functionality. This guide systematically introduces the most common types of sand casting defects, analyzes their root causes, and provides practical prevention and solution strategies to help you produce high-quality castings.

Common Types of Sand Casting Defects

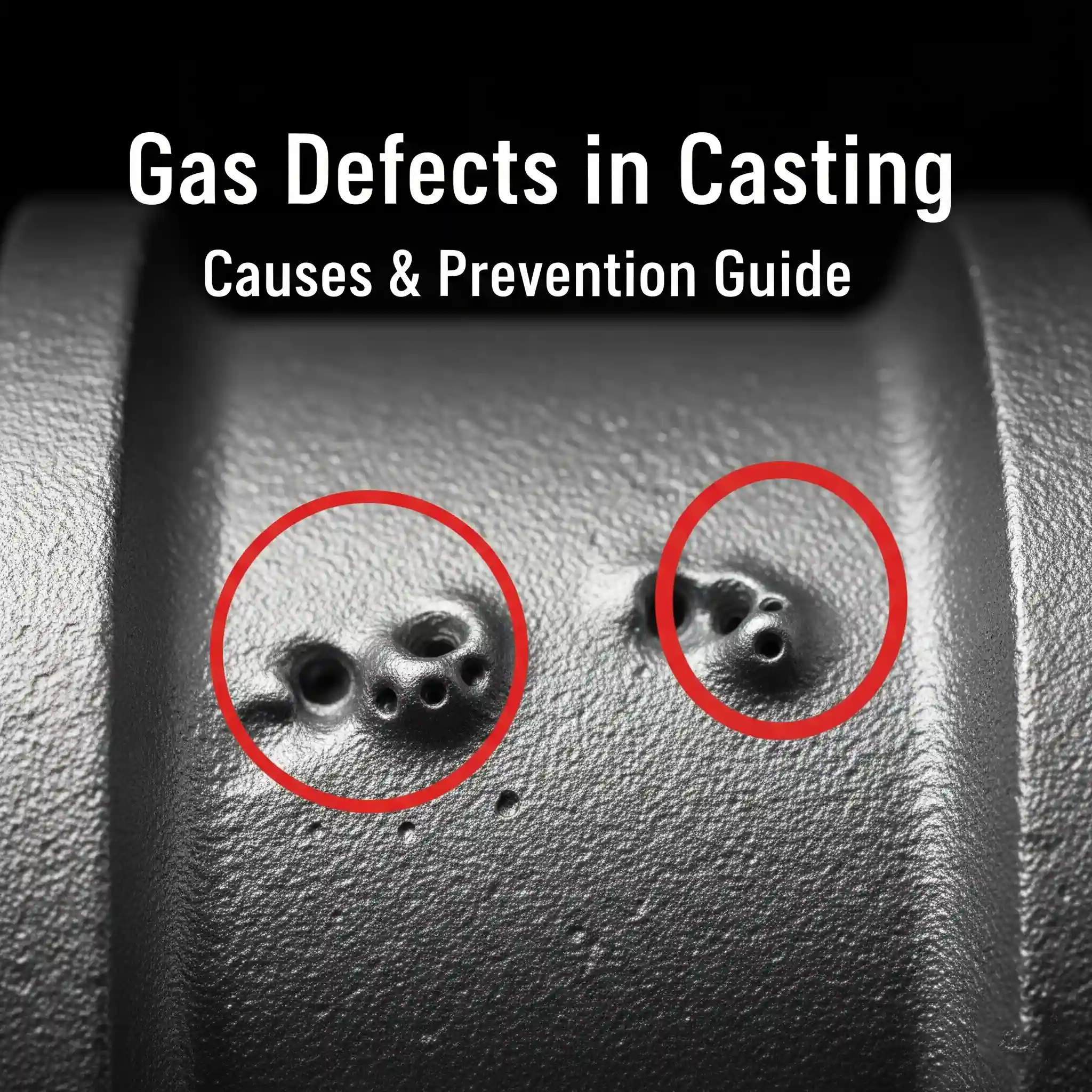

Gas Porosity (Blowholes & Pinholes)

- Description: Round or oval-shaped cavities found inside or on the surface of the casting.

- Causes: Gases trapped in the molten metal (e.g., hydrogen, nitrogen) or gases generated by the mold (e.g., from moisture) fail to escape smoothly during solidification.

- Solutions: Ensure the sand has good permeability; thoroughly bake the cores; use dry tools and equipment; and degas the metal before pouring.

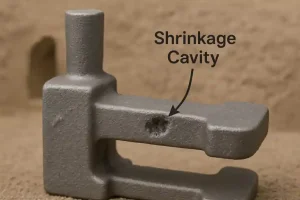

Shrinkage Defects

- Description: Irregularly shaped depressions or voids with sharp, jagged edges, found internally or on the surface.

- Causes: As the metal solidifies, it shrinks in volume. If there isn’t enough liquid metal to feed the contraction, a void is created.

- Solutions: Optimize the gating and riser system design; place risers in thicker sections; use chills to promote directional solidification.

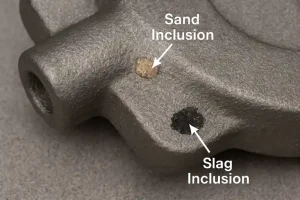

Sand & Slag Inclusion

- Description: Non-metallic impurities, such as sand grains or slag, embedded within the casting.

- Causes: The mold or core is eroded by the molten metal flow, or slag from the melting process is not properly removed and enters the mold cavity.

- Solutions: Increase the strength and compaction of the sand; use a proper gating system with slag traps or filters; and ensure thorough slag removal during melting.

Cold Shut / Misruns

- Description: A well-defined line or crack with rounded edges on the casting surface, where two streams of metal failed to fuse properly; or an incomplete casting.

- Causes: The pouring temperature is too low, leading to high metal viscosity; the pouring speed is too slow; or the gating system design is poor.

- Solutions: Increase the pouring temperature; pour the metal faster; and optimize the gate design for smooth flow.

Hot Tears / Cold Cracks

- Description: Linear cracks appearing on the casting surface, which can form during solidification or as the casting cools to room temperature.

- Causes: The mold or core offers excessive resistance to the metal’s natural contraction, causing internal stress that leads to cracking.

- Solutions: Optimize the casting’s structural design to avoid stress concentration; improve the collapsibility of the mold and cores; and use stress-relieving measures in critical areas.

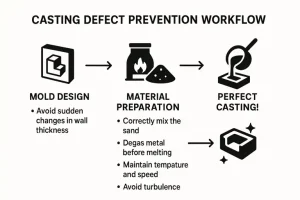

General Prevention Strategies & Best Practices

From the Source: Mold Design

- Avoid sudden changes in wall thickness to ensure uniform solidification.

Material Preparation & Control

- Correctly mix and prepare the sand to ensure optimal permeability, strength, and moisture content.

- Pre-treat metal before melting (e.g., degassing).

Precise Control of the Pouring Process

- Maintain the correct pouring temperature and speed.

- Operate safely to avoid turbulence that can trap gases.

Practice & Learning

- Gain hands-on experience through small-scale practice.

- Analyze defects to find the root cause.

Conclusion

Casting defects are an inevitable challenge in sand casting, but by understanding their types, causes, and prevention methods, you can significantly reduce their occurrence. Mastering this knowledge will not only improve your casting skills but also allow you to enjoy the rewarding process of creating a perfect, high-quality piece.