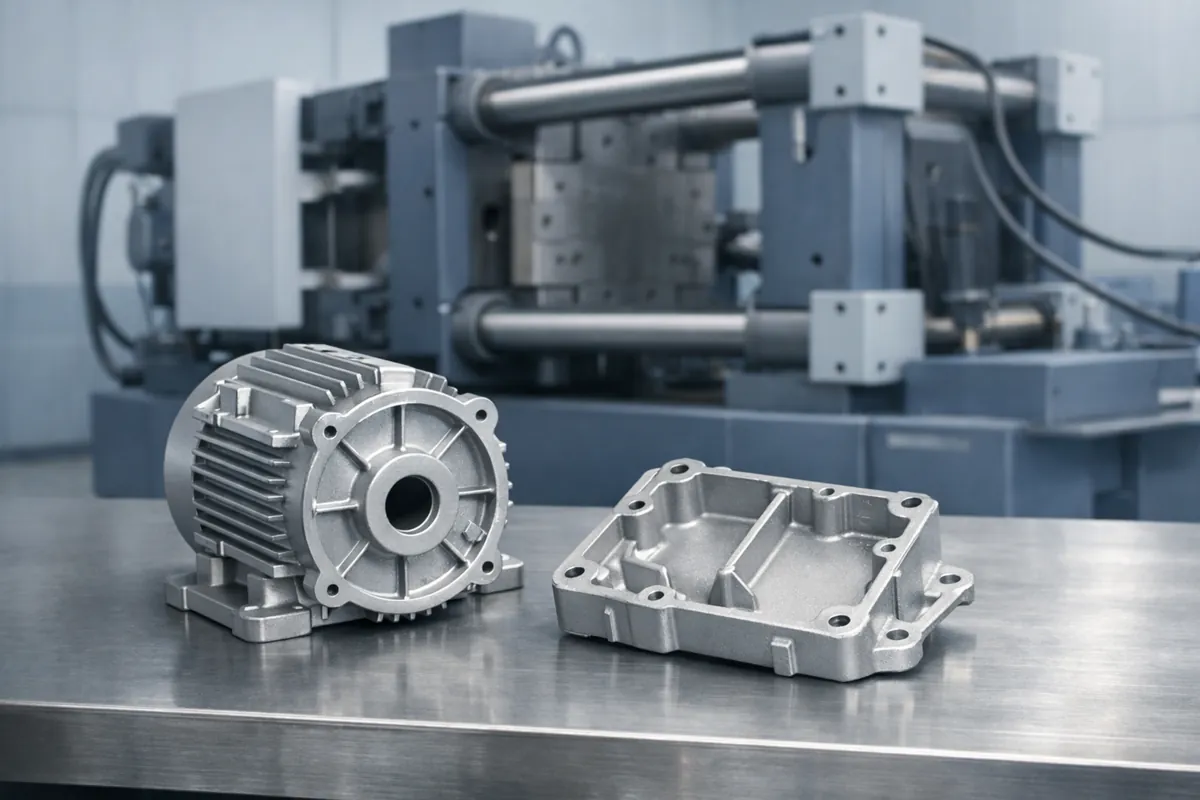

In the sand casting process, the sand mold is more than just a container for molten metal; it acts as a precise regulator that directly affects the cooling quality, dimensional accuracy, and overall production cost. The choice of mold depends on how the sand grains are bonded together to withstand the heat and pressure of the casting process.

Below, we explore the three most common types of sand molds used in modern manufacturing, analyzing their unique characteristics and ideal applications.

Three Common Sand Molding Systems in Industrial Casting

In actual production, there is no such thing as a “one-size-fits-all” sand molding solution. Process engineers must balance and choose among the following three mainstream sand molding systems based on the alloy type, structural complexity, and budget constraints.

1. Green Sand

Green sand does not actually refer to the color green; rather, it indicates that the sand is in an uncured or moist state. It is a mixture of silica sand, clay (usually bentonite), and water, essentially functioning like moist clay. Because the sand is easy to recycle and reuse, it remains the most cost-effective option for many foundries.

The production of green sand molds is straightforward and efficient, making it a popular choice for mass-producing general mechanical parts. However, because green sand is somewhat plastic and relies on physical compaction, there are risks involved. The mold may collapse or crack during the pouring process if not handled correctly. Despite this, its high efficiency and low price make it a staple in the sand casting industry.

2. Sodium Silicate or Water Glass Sand

Sodium silicate, commonly known as water glass, is ideal for casting applications that require complex internal cavities. This method involves mixing sand with liquid sodium silicate and then hardening it with $CO_2$ gas to create a high-strength mold.

This process allows for higher tolerances and is perfect for parts with high complexity, multiple cavities, and strict requirements for surface finish. It is particularly popular in Chinese manufacturing, though less common in some other countries. One unique aspect is the breakdown process; the mold can be dissolved or melted (often using hot water) to release the casting, and the materials can be collected for future projects. Its recyclability and lower material cost make it an excellent choice for balancing precision with budget.

3. Furan Resin Sand

Furan resin sand is a self-hardening process where the sand is mixed with resin and a catalyst that reacts at room temperature. This creates a mold with high rigidity and excellent thermal stability.

Compared to green sand, resin sand significantly reduces defects such as shrinkage or gas holes, producing parts with extremely accurate dimensions and clear surface details. It is the preferred choice for heavy-duty industrial components or parts where quality cannot be compromised. While the chemical additives make it more expensive than green sand and the reclamation process is more complex, it greatly reduces the scrap rate and the need for extensive post-process machining.

Conclusion

In summary, the choice of sand casting method depends entirely on your project’s specific priorities. Green sand remains the foundation of mass production due to its unmatched cost advantages and high recyclability, making it the go-to for standard industrial parts.

For complex designs and high-precision cavities, water glass sand offers a superior balance. It is particularly valued in markets like China for its ability to deliver high-quality surface finishes at a manageable material cost.

Meanwhile, furan resin sand represents the gold standard for high-quality, heavy-duty components. Its exceptional dimensional accuracy and structural integrity make it non-negotiable for engineering projects where precision is the top priority. Ultimately, selecting the right process is a strategic balance between manufacturing efficiency and the final product’s quality.

Ready to start your next casting project? Contact our engineering team today to discuss which sand casting method is best suited for your specific parts and budget. We provide professional guidance to ensure your components are delivered with precision and cost-effectiveness.