In casting, a pattern is the form used to make the mold. Many people think a pattern is just a copy of the part, but it is actually a functional tool. A pattern must include specific allowances to handle metal shrinkage and ensure the part can be removed from the sand. Choosing the right casting pattern is the first step to reducing costs and avoiding defects.

What is a Casting Pattern?

A casting pattern is a model of the part, but with extra features. These features are called allowances. In every casting pattern design, engineers must include:

-

Shrinkage Allowance: Metal gets smaller as it cools. The pattern is made slightly larger to compensate for this.

-

Draft Allowance: A slight taper is added to vertical walls so the pattern pulls out of the sand easily.

-

Machining Allowance: Extra material is added where the part needs CNC finishing later.

Pattern Configuration Matrix

| Casting Process | Pattern Configuration | Typical Material |

| Manual Sand Casting | Single or Split Pattern | Wood, Resin |

| Automated Molding | Match Plate Pattern | Aluminum, Cast Iron |

| Investment Casting | Wax Pattern | Industrial Wax |

| Lost Foam Casting | EPS Foam Pattern | Polystyrene |

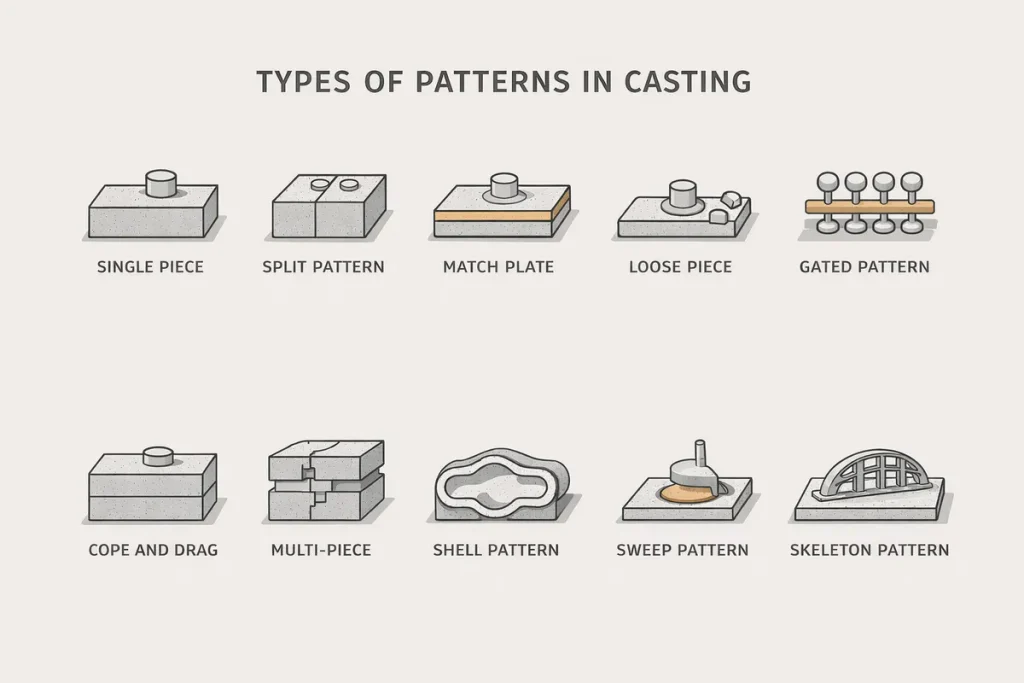

10 Common Types of Patterns in Casting

In the casting process, the choice of pattern is critical as it determines the production efficiency, cost, and geometric complexity of the final product. The following are 10 of the most widely used pattern types in the industry:

1. Single Piece Pattern

The single piece pattern is the most basic type. It is a solid model made from one piece of material like wood or metal. There are no joints or moving parts. This pattern type is common for very simple parts with no undercuts. It is the best choice for low-volume production of heavy machine bases.

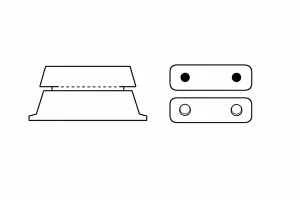

2. Split Pattern

A split pattern is divided into two parts: the cope (top) and the drag (bottom). The two halves are aligned using dowel pins. This is the standard casting pattern for parts with complex shapes. It makes it much easier to remove the pattern from the sand without damaging the mold.

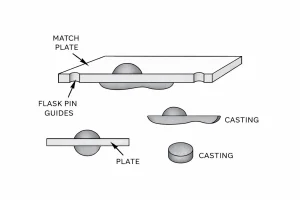

3. Match Plate Pattern

A match plate pattern is used for high-speed automated molding. The cope and drag halves of a split pattern are mounted on opposite sides of a single metal plate. This allows the top and bottom molds to be made at the same time. It is used for mass production of automotive parts.

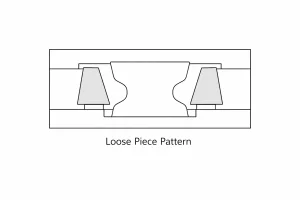

4. Loose Piece Pattern

A loose piece pattern is used when a part has “undercuts” or projections that block a straight pull. These features are made as separate pieces attached to the main pattern. After the main pattern is removed, the molder pulls the loose pieces out sideways. This avoids the need for extra sand cores.

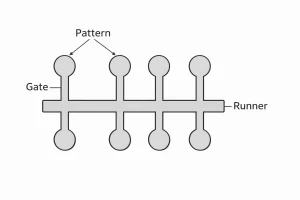

5. Gated Pattern

A gated pattern includes the gating system—the runners and gates—as part of the pattern itself. Instead of cutting gates by hand, the pattern forms the metal flow channels in the sand. This ensures every casting has the same metal flow. It is used for small, repetitive parts.

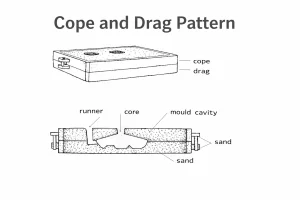

6. Cope and Drag Pattern

For very large or heavy castings, a cope and drag pattern is used. Instead of one plate, the top and bottom halves are on two separate plates. This allows two molding stations to work on the same part at the same time. It is the common choice for engine blocks.

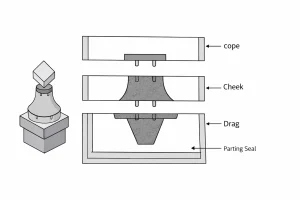

7. Multi-Piece Pattern

A multi-piece pattern uses three or more sections. This is used when a standard two-part mold cannot handle the complexity. It often includes a middle section called a “cheek.” This pattern type gives designers more freedom for complex hydraulic valve bodies.

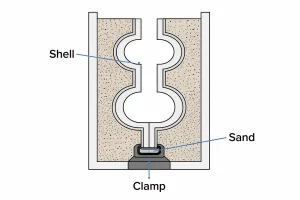

8. Shell Pattern

A shell pattern is used in shell molding, where a heated metal pattern is coated with resin-bonded sand to form a thin, rigid shell mold. Because the shell closely follows the pattern surface, it can reproduce fine details and deliver better dimensional accuracy and surface finish than conventional green sand molds. Shell patterns are typically reused many times and are widely applied in automotive, pump, and aerospace components that require precise geometry and efficient production.

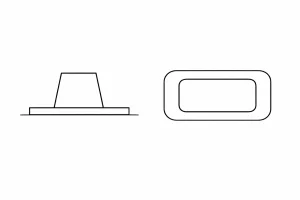

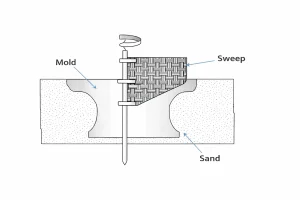

9. Sweep Pattern

A sweep pattern consists of a template or “blade” that defines the cross-section of the part. Instead of a full-scale model, the pattern is rotated or moved along a path to “sweep” the desired shape into the sand mold. This method eliminates the need for expensive, solid patterns and is ideally suited for producing large, symmetrical castings such as bells, rings, or circular lids.

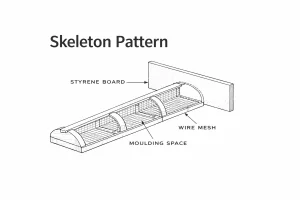

10. Skeleton Pattern

A skeleton pattern is a simplified wooden frame that outlines the general shape of a part rather than being a solid model. It is primarily used for massive castings, such as ship propellers or large water pipes. By using a framework instead of a full-scale solid pattern, this method significantly reduces material costs and solves the logistical challenge of storing oversized patterns.

Conclusion

The choice of casting pattern depends on your production volume, precision needs, and budget. For a small trial, a wood single piece pattern is enough. For mass production, a metal match plate pattern is necessary. Selecting the right pattern type early will reduce your scrap rate and manufacturing costs.

Contact our engineering team today for a technical review of your casting pattern design.