Die casting is a highly efficient and high-precision metal forming technology in modern manufacturing, particularly suited for large-volume production. This article discusses the core content regarding die casting technology, helping you gain a comprehensive understanding of its value and applications.

What is Die Casting?

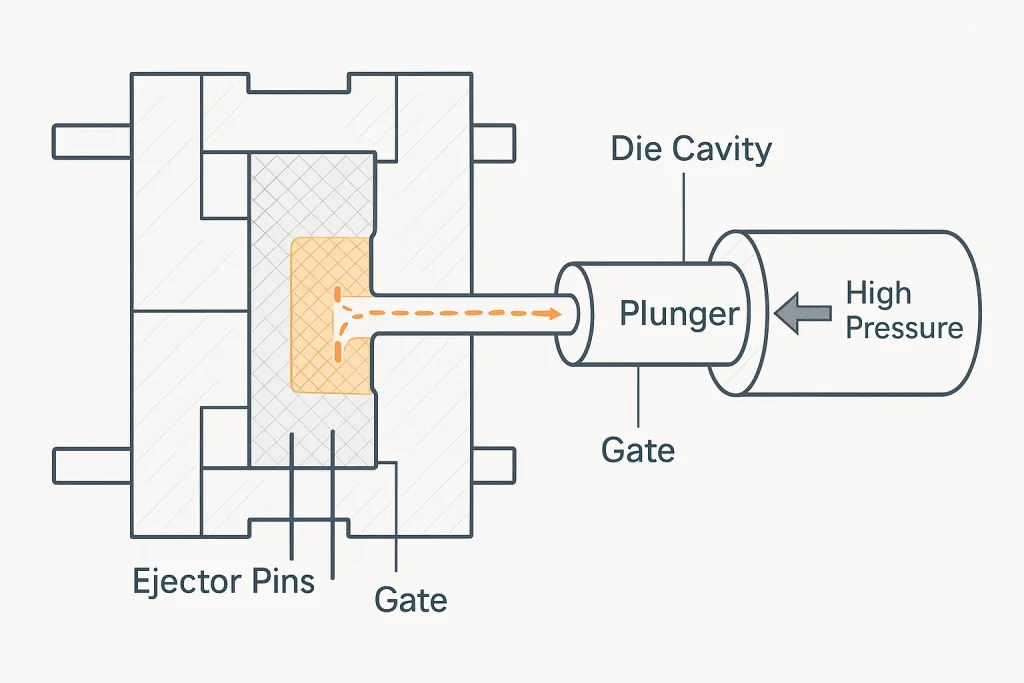

Die casting is a casting method where molten metal is rapidly injected under high pressure into a precise metal mold (Die) cavity, where it cools and solidifies under continuous pressure to form a finished part. The core characteristics of this process are high pressure, high speed, and precision tooling. The resulting castings have sharp contours, extremely high dimensional accuracy, and excellent surface finish, often ready for use as final components.

The Die Casting Process

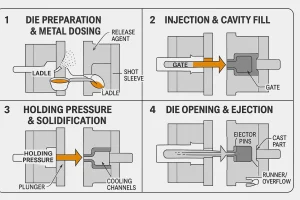

The die casting process is a high-speed, highly automated cycle consisting of four tightly controlled key steps:

- Die Preparation and Pre-treatment:

- First, the mold cavity is thoroughly cleaned, and the die temperature is precisely controlled.

- Next, a release agent (or lubricant) is uniformly sprayed onto the cavity surface. The release agent not only aids in smooth ejection but, more critically, controls the die temperature, prevents the metal from cooling too quickly, and provides necessary lubrication and protection.

- Metal Injection (High-Speed Fill):

- The die is closed and tightly clamped by the casting machine’s immense clamping force.

- A measured amount of molten metal is fed into the shot chamber, and a plunger injects it at extremely high speed and pressure (typically between 70 and 175 MPa) into the die cavity. This high-speed fill is crucial to ensure the metal completely fills complex, thin-walled sections before solidification begins.

- Pressure Application and Solidification (Holding):

- After injection, high pressure must be continuously maintained (holding stage) to compensate for the shrinkage of the metal as it cools and solidifies, and to expel residual gases.

- This stage is vital for ensuring dense internal structure, minimal porosity, and dimensional accuracy of the casting.

- Ejection and Trimming:

- Once the metal is fully solidified, the pressure is released, and the die opens.

- Ejector pins push the casting (including the gating and overflow runners) out of the cavity.

- The casting is then trimmed, either by punching or machining, to remove the excess gate, runners, and flash, completing the finishing process before secondary operations.

Types of Die Casting

Die casting processes can be categorized into various types based on machine structure, metal state, and pressure level:

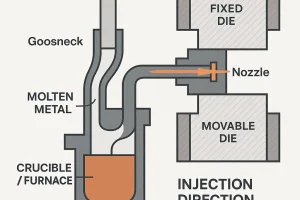

Hot-Chamber Die Casting

The melting pot is integrated with the casting machine. Suitable for low-melting-point metals (e.g., zinc, tin). The advantage is an extremely fast cycle time, ideal for small parts and ultra-high-volume production.

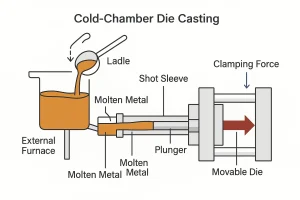

Cold-Chamber Die Casting

The melting furnace is separate from the casting machine. Suitable for high-melting-point metals (e.g., aluminum, magnesium, copper). The advantage is compatibility with a wider range of alloys, making it the preferred choice for high-strength, lightweight structural components.

Low-Pressure Die Casting

Unlike HPDC, LPDC uses lower pressure (approx. 0.08 to 0.1 MPa) to slowly push molten metal up from the bottom of a pressurized crucible into the die. The advantage is a calm fill, resulting in high-density, low-porosity castings, often used for large, axisymmetric, or pressure-tight parts (e.g., automotive wheels).

Vacuum Die Casting

A vacuum system evacuates most of the air from the die cavity before injection. The advantage is a significant reduction in internal porosity, allowing the castings to be heat-treated and welded.

Semi-Solid Casting

The metal is injected while in a slurry state, a mixture of solid and liquid phases. The advantage is stable filling at a lower temperature, which effectively minimizes porosity and shrinkage, yielding higher strength and longer die life.

Advantages of Die Casting

Die casting technology offers unique competitive advantages for manufacturing projects seeking high efficiency and quality:

- Extremely High Production Efficiency and Scalability: The short cycle time allows for hundreds of shots per hour, making it one of the most cost-effective methods for continuous, large-scale, automated production.

- Superior Dimensional Accuracy: Castings hold tight tolerances, often achieving IT13 to IT15 precision, which means little to no subsequent machining is required.

- Excellent Surface Quality: Castings have a high surface finish, often ready for many applications without further treatment, reducing post-processing time.

- Complex, Thin-Walled Part Manufacturing: The high-pressure fill capacity ensures the production of complex structures with very thin walls (down to 0.5 mm), supporting product lightweighting and integration designs.

- High Strength and Density: Rapid solidification under pressure results in a fine grain structure and low porosity, enhancing the part’s mechanical strength and durability.

Disadvantages of Die Casting

Every process has limitations, and the main constraints of die casting include:

- High Initial Investment: The cost of the die casting machines and the precision steel tooling is high, meaning the process is only economical for very large production volumes.

- Limited Material Range: It is primarily restricted to non-ferrous metals like aluminum, zinc, and magnesium, and is not suitable for ferrous metals with higher melting points (e.g., cast iron, steel).

- Risk of Porosity: Traditional HPDC can trap gas due to high-speed filling, which negatively affects the casting’s heat treatment and welding capabilities (though improved by VDC).

- Casting Size Restrictions: Conventional die casting machines are limited by their clamping force, which places constraints on the maximum size and weight of the castings.

Applicable Materials for Die Casting

Die casting is primarily suited for non-ferrous metals and their alloys that have relatively low melting points and good fluidity, as they perform excellently under pressure:

- Aluminum Alloys: The most common die casting material, offering lightweighting, high strength, and excellent electrical and thermal conductivity. Widely used in the automotive, electronics, and aerospace sectors. Common grades include A380 and ADC12.

- Zinc Alloys: Possess superior castability and fluidity, allowing for ultra-high-speed production on hot-chamber machines. Zinc alloys are high-strength and easy to plate/finish, frequently used for precise, complex electronic housings and connectors.

- Magnesium Alloys: The lowest-density structural metal, providing extreme lightweight advantages. Popular in automotive and portable electronics for maximum weight reduction.

- Copper Alloys (Brass): Offer high hardness, excellent corrosion resistance, and mechanical strength. Due to their high melting point, they typically require cold-chamber machines and are mainly used for structural or highly wear-resistant parts.

Applications of Die Casting

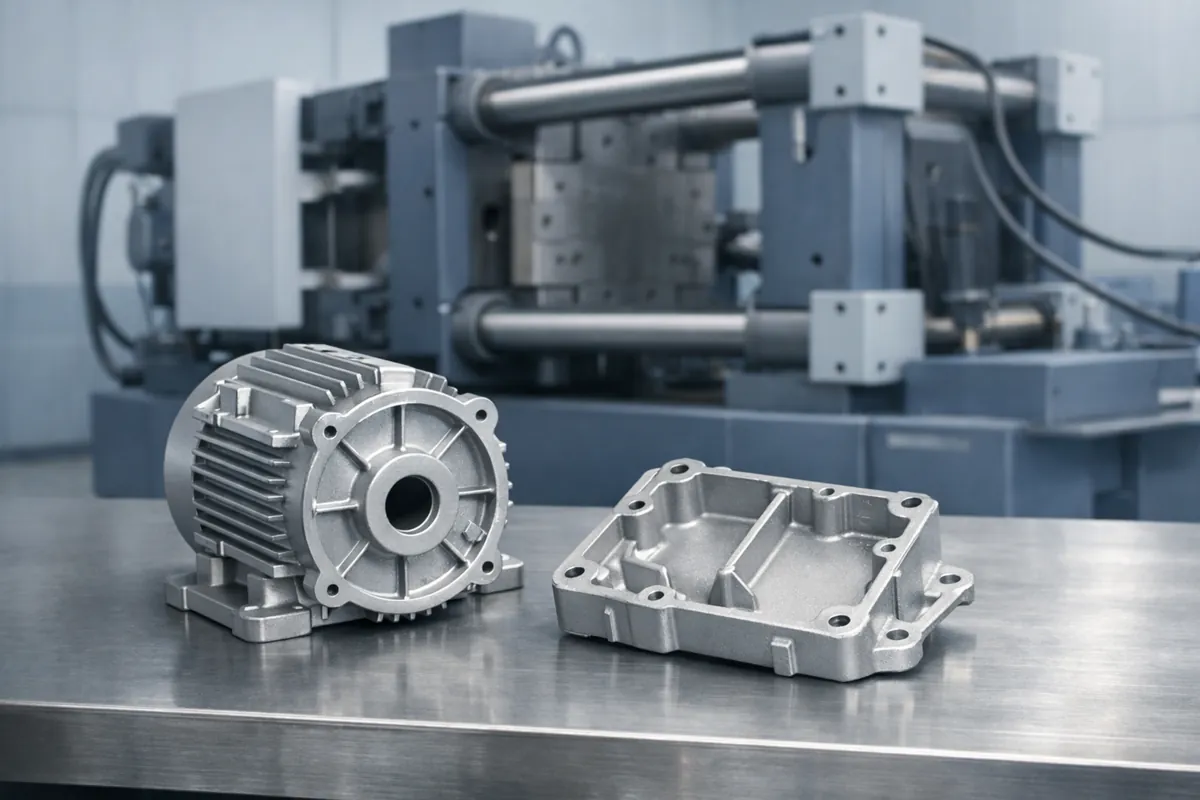

Die castings are widely used in industries requiring high precision, consistency, and rapid supply:

- Automotive Industry: Engine blocks, transmission housings, heat sinks, and structural components (e.g., giga-castings).

- Electronics and Telecommunications: Electronic enclosures, LED lamp housings, heat sinks, and precision connectors.

- Machinery and Equipment: Pump bodies, valve bodies, and hydraulic system parts.

- Consumer Goods: Power tool housings and major appliance components.

Summary

Die Casting is the ideal solution for manufacturing high-precision, high-volume, lightweight non-ferrous metal parts. MinHe Casting specializes in high-quality aluminum, zinc, and magnesium die casting services, and also utilizes technologies like sand casting, ensuring we provide the optimal manufacturing solution for our clients. We operate under the ISO 9001 quality system to guarantee your custom castings meet the most rigorous performance and dimensional requirements. If you are seeking high-quality precision die casting services, contact our engineering experts today to discuss your project needs and receive a custom casting quote.