Continuous Casting (CC) plays a pivotal role in modern metallurgy, transforming how molten metal solidifies into continuous semi-finished products such as billets and slabs. Compared to traditional Ingot Casting, CC offers far greater efficiency and product consistency by eliminating several intermediate, energy-intensive steps. This makes it the preferred process for medium-to-high-volume metal production, producing slabs, blooms, and billets as feedstock for subsequent rolling and extrusion.

What Is Continuous Casting

Continuous Casting is an industrial process that utilizes a water-cooled crystallizer (Mold) to continuously solidify molten metal, thereby forming a semi-finished product (cast billet or semi-finished slab/plate) with a constant geometric shape.

The core difference between Continuous Casting and the ingot method is the continuity of the process: in CC, the metal is continuously poured and solidified, producing a semi-finished product that is theoretically infinitely long; the ingot method is intermittent, producing fixed-size ingots. Thus, the continuous casting process is linear and highly automated.

The central piece of equipment in this process is the Continuous Casting Machine (CCM).

How the Process Works

Continuous Casting leverages the continuity of the flow and a high level of automation to ensure product quality and production efficiency. Key control parameters include stable molten metal level, uniformity of initial solidification (primary shell), and precise control of the withdrawal speed.

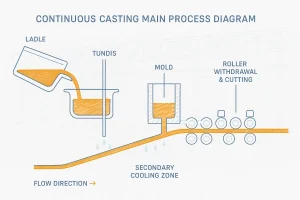

Step-by-step process flow of continuous casting, from molten metal pouring to billet cutting and storage.

1. Metal Transfer and Flow Control

Molten metal is transferred from the ladle to the tundish. The tundish serves to buffer the flow, stabilize the pouring pressure and liquid level, and is a critical area for inclusion removal. The liquid metal enters the water-cooled crystallizer through a Submerged Entry Nozzle. The key in this phase is maintaining a stable liquid level and precise flow control to ensure smooth pouring.

2. Mold Zone and Initial Solidification

This is the heart of the continuous casting process. The molten metal contacts the water-cooled copper crystallizer, rapidly dissipating heat and forming a thin, uniform primary shell.

In the crystallizer zone, the role of mold flux (or protective slag) is crucial. Applied to the molten metal surface inside the crystallizer, it melts to form a lubricating, insulating, and protective layer. The molten slag flows between the shell and the mold wall, providing lubrication to reduce friction; the slag layer on the surface provides insulation and prevents steel oxidation; and crucially, it actively prevents sticking (sticking).

Furthermore, the crystallizer must undergo slight high-frequency oscillation to periodically break the bond between the primary shell and the mold wall, further optimizing surface quality.

3. Secondary Cooling and Withdrawal

Upon exiting the crystallizer, the casting only has a fragile solidified shell. The process then enters the secondary cooling zone, where the casting is intensely cooled, typically via water spray ( spray cooling ) or water immersion, until complete solidification is achieved. This is a critical step in the continuous casting process.

Roller support and withdrawal speed control must be precise to determine the solidification length and production rate. CCM structures include the common curved type, as well as vertical type and horizontal type.

4. Cutting and Handling

Once the casting is fully solidified, it is withdrawn at a constant speed by the roller traction system. Subsequently, it is cut to pre-determined lengths by flame cutting machines or shears. The cut billets can often be sent directly to the downstream rolling production line (hot charging), which significantly saves reheating energy consumption and time.

Materials Used

Continuous Casting is a highly versatile technology applicable to multiple metal systems:

- Steel: The primary application material, including carbon steel, alloy steel, and stainless steel. During steel casting, Electro-Magnetic Stirring (EMS) is often used to optimize the solidification structure and precisely control internal defects such as center segregation.

- Aluminum: Typically uses CC variants like strip casting or twin-roll casting. These materials require more precise control over heat exchange efficiency and inert gas protection to suppress oxidation.

- Copper and its Alloys: Due to its extremely high thermal conductivity, stringent control over the cooling rate is necessary to prevent cracking and internal stress.

Advantages

Continuous Casting offers significant technical and economic benefits in metallurgical production:

- High Metal Yield: Metal yield typically exceeds 90% ( $>90\%$ ), substantially reducing the head and tail losses associated with the traditional ingot method.

- Energy Savings and Efficiency: Eliminates intermediate steps like ingot stripping and soaking furnace reheating. Specifically, the capability for hot charging significantly reduces reheating energy consumption and shortens the total production cycle.

- Product Quality and Consistency: Continuous and stable solidification conditions form a uniform fine-grain structure, ensuring high consistency in billet dimensional accuracy and internal structure.

- Automation and Integration: The entire process is highly automated, facilitating the integration of advanced digital control systems, and allowing direct integration with downstream rolling lines.

Limitations

Despite its benefits, the continuous casting process has inherent limitations:

- High Capital Investment: The design, manufacturing, and installation costs of the CCM are very high.

- Limited Cross-Section Shapes: Primarily suitable for producing billets with a constant cross-section (slabs, blooms, rounds), making it difficult to adapt to complex or non-constant geometries.

- Narrow Process Window: The requirements for parameters such as pouring temperature, withdrawal speed, and cooling intensity are extremely strict, demanding precise and stable control.

- Low Alloy Switching Flexibility: The transition and adjustment periods between different alloys or specifications are relatively long, and cleaning is complex.

Applications

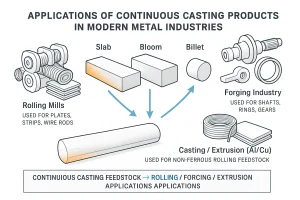

Technical illustration showing how continuous casting feedstock—slabs, blooms, and billets—are used for rolling, forging, and extrusion processes.

Continuous Casting applications cover all major metal material industries:

- Steel Industry: The vast majority of steel slabs, blooms, and billets are produced by CC, serving as raw materials for rolling plates, profiles, and wire rods.

- Aluminum Industry: Widely used in processes like strip casting and twin-roll casting, as feedstock for aluminum foil, sheet, and plate.

- Copper and Brass: Used to produce continuous rods, tubes, and wire rod feedstock required for electrical wiring.

Comparison

Continuous Casting holds a unique position in terms of efficiency and volume:

- Vs. Ingot Casting: Continuous Casting holds a decisive advantage in efficiency, uniformity, and yield.

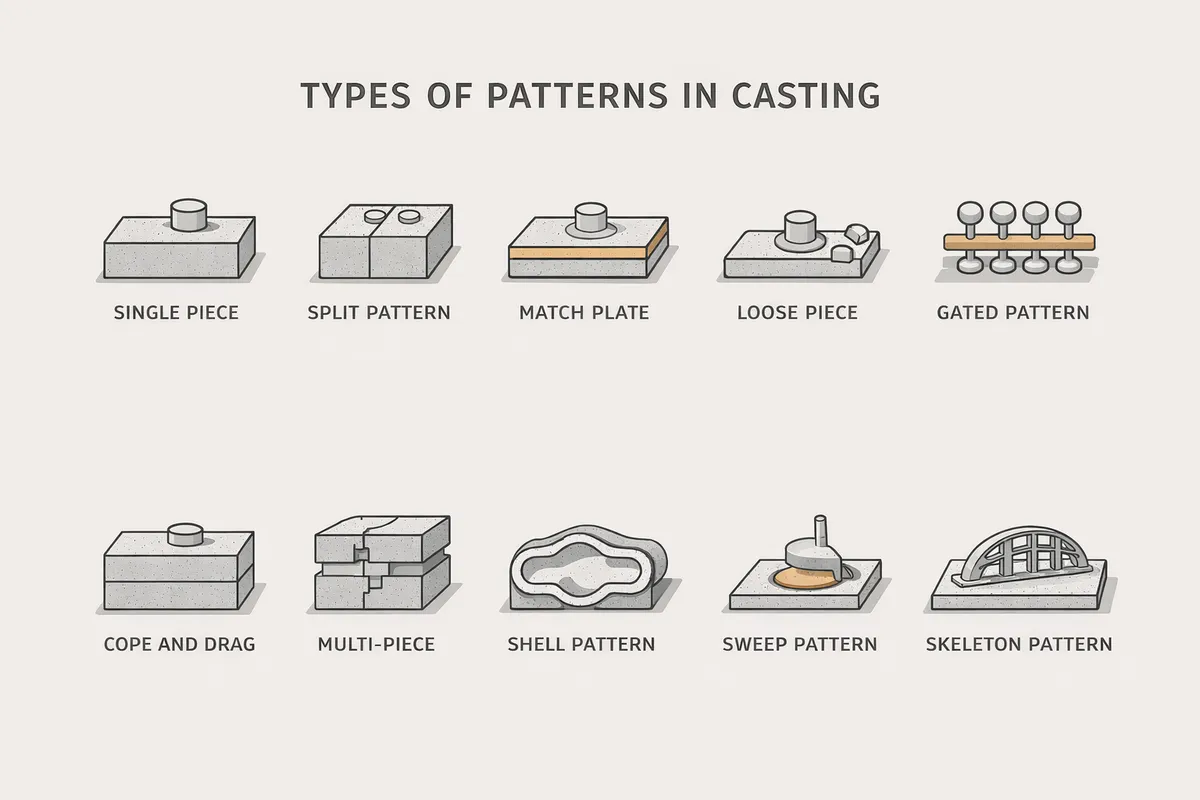

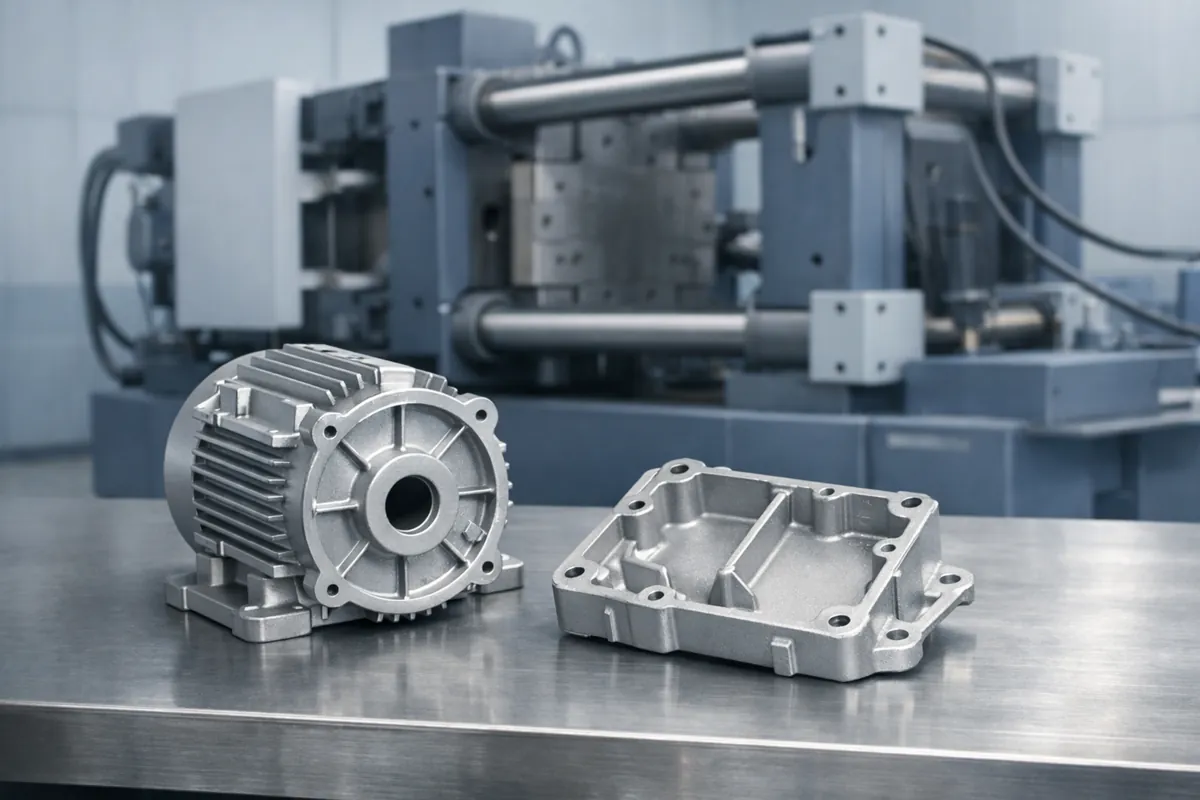

- Vs. Sand Casting: Sand casting is used to produce final or near-final shape parts with complex geometries; CC focuses on the efficient production of continuous semi-finished products.

- Vs. Direct Chill (DC) Casting: DC casting is primarily used for aluminum ingots. It pours molten metal directly into a water-cooled mold while sinking slowly, offering higher cooling rates. The fundamental difference from traditional CC is that DC is a semi-continuous or batch ingot process, rather than achieving theoretically infinite continuous production.

Conclusion

Continuous Casting demonstrates outstanding modern engineering value through its characteristics of high efficiency, high consistency, and production integration. By eliminating intermediate steps, optimizing product quality, and saving resources, it has become a foundational technology for the global metallurgical industry. Therefore, it will maintain its core position in medium-to-high volume metal production.

Ready to start your project? Contact our engineers for a detailed casting evaluation.