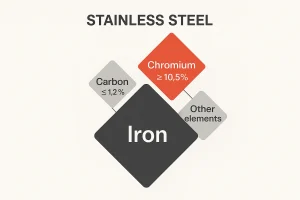

Stainless steel is an alloy of iron, chromium, and small amounts of other elements. Its unique properties are derived from the fact that it contains at least 10.5% chromium, which is the key ingredient that provides its superior corrosion resistance, allowing it to remain durable and stable in a wide range of harsh environments.

This article will provide a comprehensive breakdown of stainless steel’s composition, types, characteristics, and its widespread applications in various fields.

The History of Stainless Steel

Did you know how stainless steel was discovered? Its birth was, in fact, a complete accident.

Back in 1913, a British metallurgist named Harry Brearley was busy trying to find an alloy for gun barrels that wouldn’t rust. He ran countless experiments, but none seemed to work. He eventually discarded a sample with a high chromium content and just left it in a scrap pile, paying it no mind.

Months later, when he happened to look through the pile again, he was astonished to find that while all the other ordinary steel samples had rusted away, the one he’d forgotten about was still bright and shiny. This seemingly insignificant find unlocked the secret to stainless steel’s corrosion resistance and went on to completely change our world.

How Is Stainless Steel Made?

The creation of stainless steel is a complex and precise industrial process. From raw materials to the finished product in our hands, it goes through several key steps.

1. Melting and Casting

Imagine a giant furnace. This is where all the raw materials—like stainless steel scrap, iron, and chromium—are melted down in a high-temperature process that can take 8 to 10 hours. After cooling, the molten steel is cast into semi-finished forms like large slabs, billets, bars, and round tubes, preparing them for their next transformation.

2. Forming

Next, these semi-finished products are heated up and then rolled through massive rollers. Much like rolling out dough, slabs and billets are flattened into plates and sheets, while bars are turned into wires and rods. This step gives stainless steel the basic shapes we’re all familiar with.

3. Heat Treatment

After being shaped, the stainless steel has to go through a “tempering.” This process, called annealing, involves heating the metal and then cooling it in a controlled manner to relieve internal stress and soften it. This stage is extremely delicate, as different cooling speeds and temperatures can drastically alter the steel’s properties. For instance, a rapid cooling process can increase the steel’s strength without compromising its toughness.

4. Descaling

After annealing, a layer of oxide scale forms on the steel’s surface. To restore its clean finish, it undergoes a descaling process. The most common method is pickling, which uses a nitric-hydrofluoric acid solution to clean the steel. Another method, electro-cleaning, uses an electric current and a phosphoric acid solution. The choice of process depends on the specific type of steel.

5. Cutting

Before the final product is made, the steel usually needs to be cut to precise shapes and sizes. There are many methods, from basic mechanical cutting with shears and circular blades, to high-speed sawing, stamping, and blanking. For thicker steel, flame cutting and plasma beam cutting are used.

6. Finishing

This is the final and crucial step that gives stainless steel its polished look, especially for products directly facing the end user. Through a series of polishing and grinding, the steel can achieve various surface finishes, from a matte look to a bright, reflective, or even mirrored appearance. After all these steps, the steel is finally ready to be sold and shipped around the world.

Composition of Stainless Steel

Here are the key elements that make up stainless steel:

- Iron (Fe): The main base element of the alloy.

- Chromium (Cr): The most crucial element. When its content exceeds 10.5%, it forms the dense, passive layer on the surface that prevents corrosion.

- Carbon (C): Affects the hardness and strength of the steel.

- Nickel (Ni): Improves the steel’s toughness, ductility, and corrosion resistance, especially against acids.

- Molybdenum (Mo): Significantly enhances the steel’s resistance to pitting corrosion in chloride environments, such as saltwater.

- Other Elements: Including manganese, silicon, and nitrogen, which are used to fine-tune the steel’s properties.

Types of Stainless Steel

Based on their microstructure and main properties, stainless steels are classified into several major families:

- Austenitic Stainless Steel: The most common type, known for its excellent corrosion resistance, ductility, and weldability. It is generally non-magnetic.

- Martensitic Stainless Steel: Can be heat-treated to achieve high hardness and strength, but with relatively lower corrosion resistance. It is magnetic.

- Ferritic Stainless Steel: Offers good corrosion resistance and oxidation resistance at a relatively lower cost. It is magnetic.

- Duplex Stainless Steel: Combines the best properties of both austenitic and ferritic structures, offering a mix of high strength and superior corrosion resistance.

- Precipitation-Hardening (PH) Stainless Steel: Can achieve extremely high strength and hardness through a special heat treatment process while maintaining good corrosion resistance.

Common Grades of Stainless Steel

The table below shows some common casting grades for each type:

| Type | Common Casting Grades | Corresponding Standard Grades | Key Properties | Applications |

| Austenitic | CF8, CF8M | 304, 316 | Corrosion resistant, good ductility | Food processing equipment, kitchenware, chemical containers, marine components (316) |

| Martensitic | CA15, CA40 | 410, 420 | High hardness, high strength | Cutlery, valves, turbine blades, surgical instruments |

| Ferritic | CA6NM | 430 | Lower cost, good corrosion resistance | Automotive exhaust systems, kitchen appliances, furnace parts |

| Duplex | CD4MCu | 2205 | High strength, superior corrosion resistance | Chemical processing, oil and gas industry, marine environments, structural components |

Characteristics of Stainless Steel

Core Performance

-

Exceptional Corrosion Resistance: Stainless steel’s most famous characteristic is its outstanding resistance to corrosion. This is thanks to a minimum of 10.5% chromium in its alloy, which forms an invisible, self-repairing passive layer on the metal’s surface. This protective film allows stainless steel to withstand a wide range of corrosive media, including moisture, chemicals, and saltwater.

-

High Strength and Toughness: Stainless steel boasts excellent mechanical properties. It can endure high-pressure and impact loads, making it widely used in structures that require strength and impact resistance, such as buildings, bridges, and various industrial equipment. Its good toughness also prevents it from fracturing, ensuring safety in its applications.

-

Good Fabricability: Stainless steel is not difficult to work with. It can be easily processed into a wide range of complex shapes through various methods including casting, forging, welding, and cutting. This versatility makes it an ideal material for applications in the automotive, aerospace, and precision instrument industries.

-

Excellent Heat and Cold Resistance: Certain grades of stainless steel can maintain their stable performance at extremely high or low temperatures without becoming brittle or soft. This makes it a preferred material for manufacturing critical components like furnace parts, cryogenic containers, and rocket engines.

Outstanding Advantages

-

Safety and Hygiene: Stainless steel’s smooth, non-porous surface does not harbor bacteria and will not leach any harmful substances into food or the human body. This makes it a benchmark for hygiene and a top choice for medical instruments, tableware, and food processing equipment. Its easy-to-clean nature also significantly reduces maintenance costs and the risk of cross-contamination.

-

Aesthetics and Maintenance: Stainless steel has a unique, modern appearance and a natural luster that doesn’t require any coating or plating. Its resistance to scratches and stains means it is easy to maintain, and a simple wipe with a cleaner is all it takes to restore its shine. This makes it highly popular in architecture, kitchens, and consumer product design.

-

High Recyclability and Environmental Friendliness: Stainless steel is a highly sustainable “green” material. Because it contains valuable alloy elements like chromium and nickel, recycling stainless steel is economically very attractive, and its recycling rate is close to 100%. This forms a highly efficient “furnace-to-furnace” circular economy, which significantly reduces the need for new mineral mining and minimizes its environmental footprint.

Typical Uses of Stainless Steel Castings

The combination of stainless steel’s properties with the flexibility of casting has made stainless steel castings an ideal choice for manufacturing complex parts. Stainless steel castings are widely used in:

- Chemical and Petrochemical Industries: For components like pump bodies, valves, impellers, and pipe fittings that handle corrosive fluids.

- Food and Beverage Industry: For manufacturing various hygienic-grade equipment, such as mixers, filters, and containers.

- Marine and Naval Engineering: For marine hardware, propellers, and seawater pumps due to their resilience against saltwater corrosion.

- Medical Devices: For surgical instruments, implants, and other medical equipment components.

Frequently Asked Questions (FAQ)

Here are answers to some of the most common questions about stainless steel.

What is the difference between stainless steel and regular steel?

The most essential difference is chromium. Regular steel, which is mainly made of iron and carbon, rusts easily in a humid environment. In contrast, stainless steel contains at least 10.5% chromium, which forms an invisible, self-healing passive layer on the surface. This protective layer is what gives stainless steel its superior corrosion resistance.

Is stainless steel magnetic?

Most common austenitic grades of stainless steel, such as 304 and 316, are generally non-magnetic in their annealed state. However, they can become weakly magnetic after cold working or welding. Other types, like martensitic and ferritic stainless steels, are magnetic.

How do you know if something is stainless steel?

While a definitive test requires a lab, you can perform a basic check by using a magnet. If the material is strongly attracted to the magnet, it is likely a magnetic type of stainless steel or another steel alloy. You can also look for markings and check the material’s reaction to an acid test for a more conclusive result.

Can stainless steel be welded?

Yes, stainless steel is weldable, but the process requires specific techniques to maintain its corrosion resistance. Proper heat management and the use of appropriate welding materials are crucial to ensure the final weld retains the desired properties.

Contact Us

Want to find the most suitable stainless steel material for your project? Our team of experts is ready to provide you with professional consultation and customized solutions. Whether you need to understand the performance differences between various grades or require expert advice for a specific application, we are here to offer comprehensive support. Contact us now for a free quote and technical support.