Understanding the Basics of Heat Treatment

Heat treatment is a controlled process of heating and cooling metals to alter their physical and mechanical properties without changing the product shape. This technique is essential in metalworking, helping manufacturers enhance hardness, ductility, tensile strength, and wear resistance for various industrial applications.

While there are several sub-processes under the umbrella of heat treatment, four major types are commonly used in practice. Each has a distinct purpose and application based on the material and desired outcome.

1. Annealing

Annealing involves heating the metal to a specific temperature and then allowing it to cool slowly, usually inside a furnace. This process helps to:

- Soften the metal for improved machinability

- Reduce internal stresses

- Refine the grain structure

- Enhance ductility

It’s particularly useful for metals like stainless steel, copper, and aluminum, which are prone to work hardening during fabrication.

Diagram of the annealing process phases.

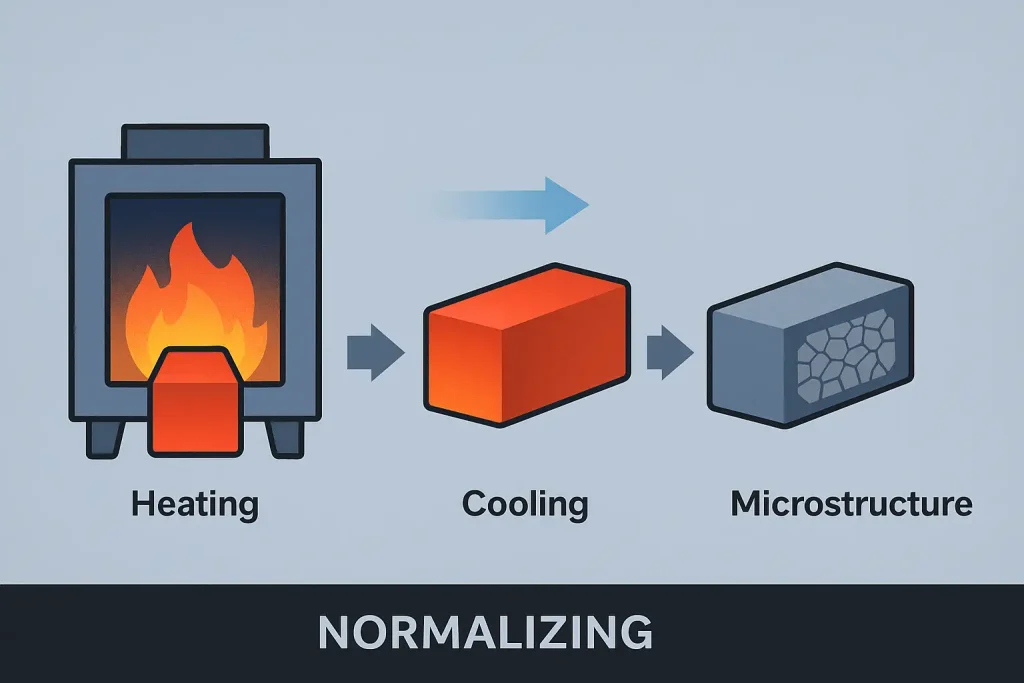

2. Normalizing

Primarily used for ferrous metals, normalizing involves heating the metal above its critical temperature and then air-cooling it. The result is a uniform grain structure and improved mechanical properties.

Key benefits include:

- Better dimensional stability

- Improved toughness

- Enhanced machinability

- Elimination of structural irregularities caused by casting or welding

Normalizing is often a preparatory step before further processing such as machining or quenching.

Stages of the normalizing heat treatment method

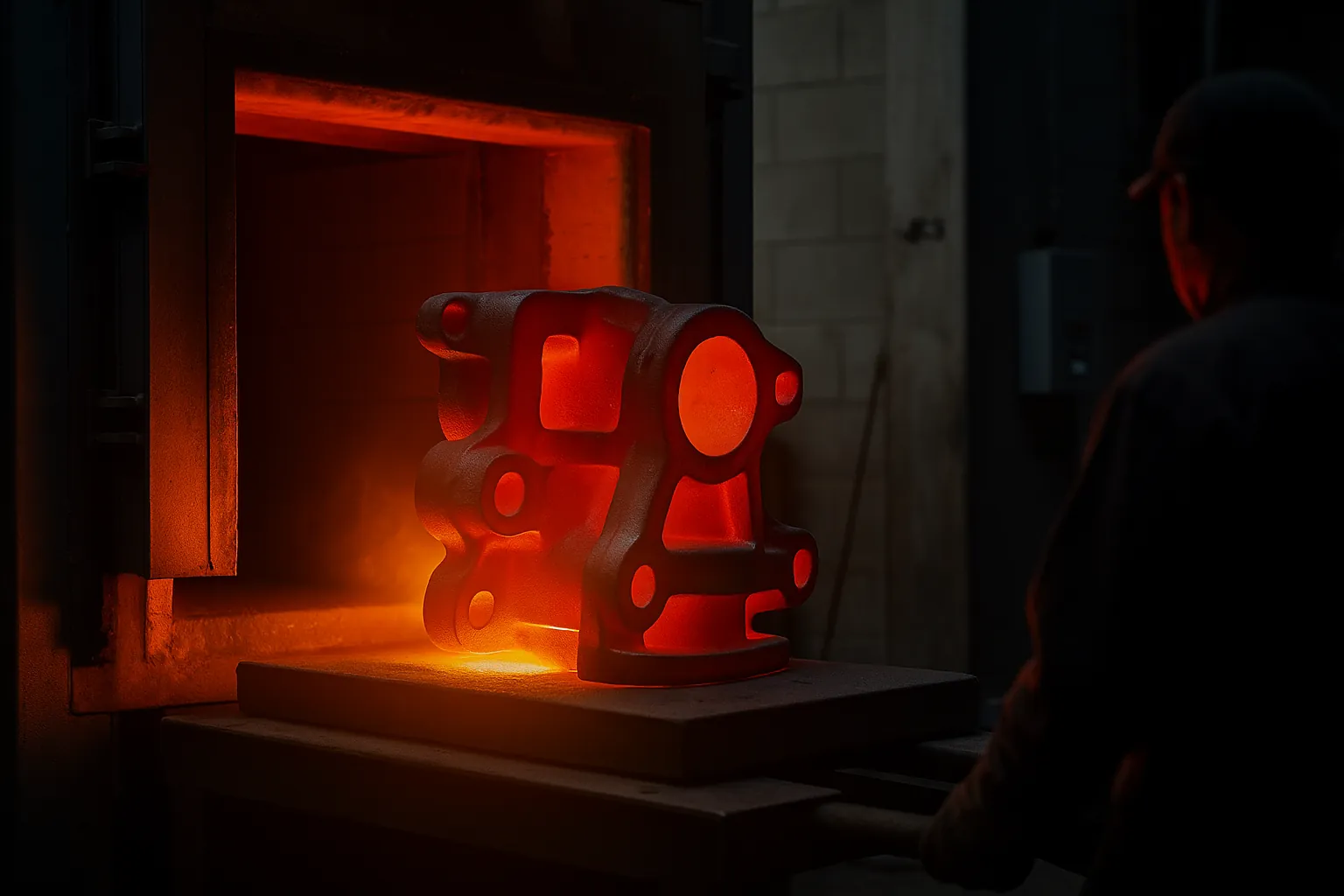

3. Quenching

Quenching involves heating the metal to a high temperature and then rapidly cooling it using a quenching medium—typically water, oil, or air. This sudden cooling traps the carbon atoms in place and hardens the metal.

Advantages of quenching include:

- Significant increase in hardness

- Improved wear resistance

- Shorter processing time compared to slow cooling methods

However, quenching can also make the metal brittle. That’s why it’s often followed by tempering to relieve internal stresses and adjust mechanical properties.

Illustration of the metal quenching process phase

4. Tempering

Tempering is a heat treatment process performed after quenching. It involves reheating the hardened metal to a lower temperature and then cooling it at a controlled rate. The purpose is to reduce brittleness while maintaining an optimal balance of hardness and toughness.

Tempering is essential for:

- Enhancing durability and flexibility

- Reducing internal stress from quenching

- Adjusting mechanical properties to suit specific applications

The exact temperature used during tempering depends on the desired final characteristics. For example, lower temperatures retain more hardness, while higher temperatures increase ductility.

Visual representation of tempering process in metallurgy

Final Thoughts

Each of the four main heat treatment methods—annealing, normalizing, quenching, and tempering—serves a distinct role in enhancing the mechanical performance of metals. Whether you’re working with cast steel, ductile iron, or aluminum alloys, understanding these processes is key to achieving desired strength, ductility, and durability.

For deeper insights into how heat treatment fits into the overall production cycle, you may also be interested in our guide on post-casting heat treatments and the impact of casting defects on material performance.

Need help choosing the right treatment for your casting project? Contact our engineering team to discuss your application and production needs.