What is Ductile Iron?

Ductile iron, also known as spheroidal graphite cast iron or nodular cast iron, is a cast iron alloy renowned for its superior mechanical properties. Its core advantage lies in its unique spheroidal graphite microstructure.

The composition of ductile iron is precise and complex, including:

-

Carbon (C): 3.0% – 4.0%

-

Silicon (Si): 1.8% – 2.8%

-

Manganese (Mn): 0.1% – 0.5%

-

Sulfur (S): < 0.02%

-

Phosphorus (P): < 0.08%

-

Magnesium (Mg): 0.03% – 0.06%

-

Rare Earth Elements (RE): 0.01% – 0.05%

Unlike the flake-like graphite in traditional gray cast iron, the graphite in ductile iron exists in a nodular form. This fundamental change in microstructure drastically improves the material’s properties, making it far superior to conventional cast iron.

Origin of Ductile Iron

Ductile iron isn’t a material that was discovered by accident. It’s a landmark modern invention that came about in the late 1940s.

Before its creation, cast iron was notoriously brittle. This was because its internal graphite formed into sharp flakes, which created weak points that made the material prone to shattering.

The true breakthrough happened in 1943 when Dr. H. Morrogh of the British Cast Iron Research Association discovered that adding cerium to molten iron could change the graphite’s shape. At nearly the same time, Keith Millis of the U.S. International Nickel Company independently discovered a similar effect by using magnesium.

It was the tireless work of these scientists that led to the birth of ductile iron. The innovation completely transformed the material’s properties, making the internal graphite into strong, tough spheres instead of brittle flakes. This gave ductile iron the strength and toughness of steel, allowing it to be widely used in modern industry.

Ductile Iron’s Microstructure

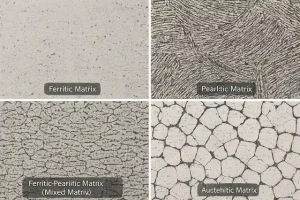

Ductile iron’s performance is determined by its unique microstructure, which is composed of spheroidal graphite dispersed within a metallic matrix. This metal matrix is a crystalline structure formed by iron and carbides at various temperatures, and its type directly dictates the material’s lefinal mechanical properties.

Here are the primary types of matrices:

-

Ferritic Matrix:

-

What It Is: A soft and ductile crystalline structure of pure iron with a small amount of dissolved carbon.

-

Properties: Offers high ductility and excellent toughness, but with a relatively lower strength.

-

Applications: Commonly used for components that require high impact resistance and plasticity.

-

-

Pearlitic Matrix:

-

What It Is: A layered crystalline structure of ferrite and iron carbide (cementite).

-

Properties: Characterized by high strength, high hardness, and good wear resistance, but less ductile than a ferritic matrix.

-

Applications: Ideal for manufacturing components that require both high strength and good wear resistance, such as crankshafts and gears.

-

-

Ferritic-Pearlitic Matrix (Mixed Matrix):

-

What It Is: A mixture of ferrite and pearlite.

-

Properties: Provides a balanced combination of strength and toughness.

-

Applications: The most common matrix type, suitable for a wide range of general engineering parts.

-

-

Austenitic Matrix:

-

What It Is: A solid solution of carbon in iron formed at higher temperatures.

-

Properties: Possesses excellent corrosion resistance, heat resistance, and high toughness.

-

Applications: Used in specialized environments for applications like heat-resistant valves and pump bodies.

-

The perfect combination of spheroidal graphite and a suitable metal matrix is what gives ductile iron both the excellent castability of iron and the superior mechanical properties of steel.

Advantages of Ductile Iron

Ductile iron is a revolutionary material that combines the best properties of both traditional cast iron and steel.

- Superior Strength and Toughness: The spherical graphite structure gives ductile iron a very high tensile strength and excellent impact resistance.

- Exceptional Ductility: Unlike brittle cast irons, it can undergo plastic deformation similar to steel before breaking, which is crucial for safety and durability.

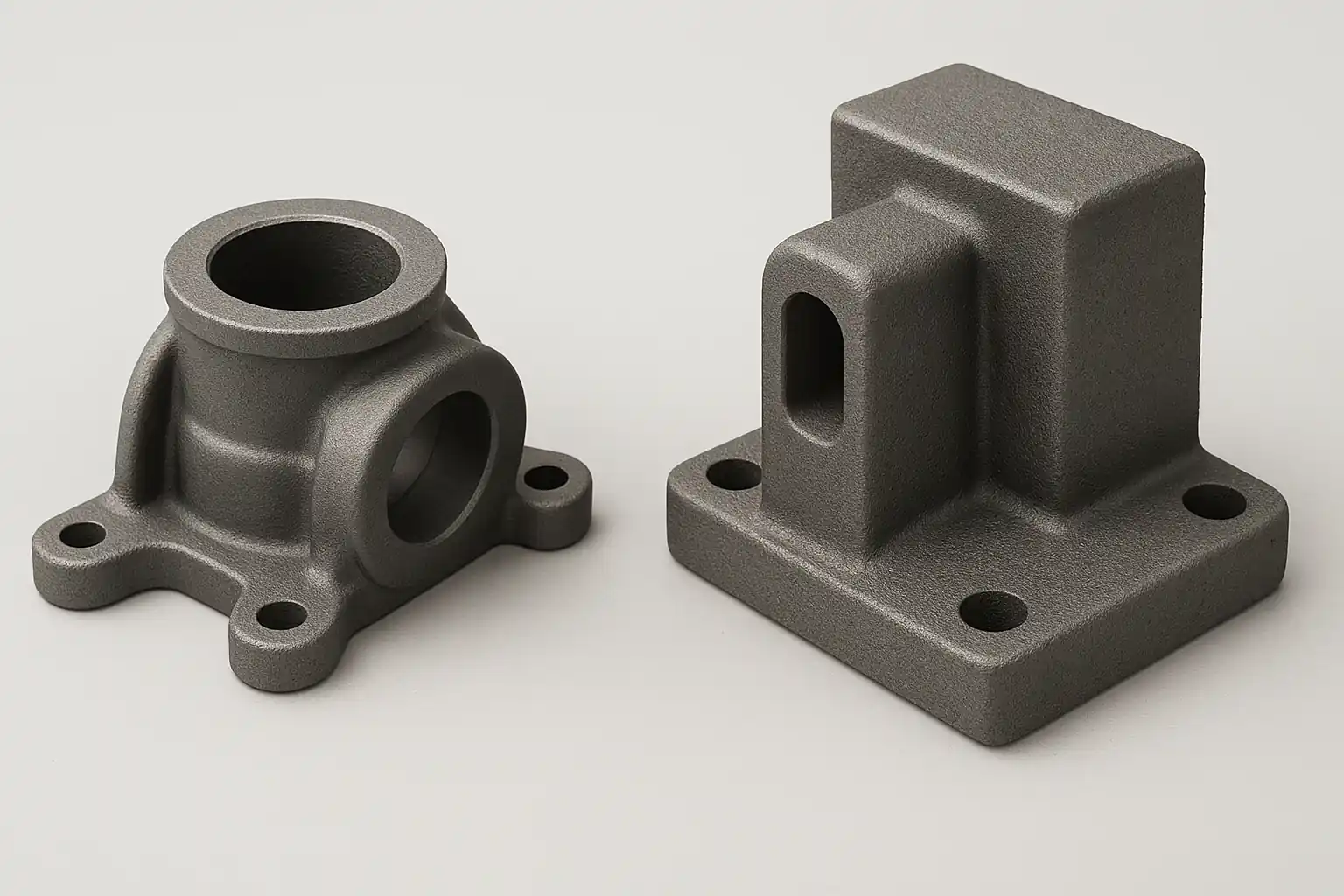

- Excellent Castability: It has great fluidity and low shrinkage, allowing for the precise manufacturing of complex, intricate parts.

- Long-lasting Durability: Inheriting the wear and corrosion resistance of cast iron, it ensures products can perform reliably in harsh environments for a long time.

Ductile Iron Performance

The specific performance of ductile iron is defined by its grade, which directly reflects its key mechanical properties.

- Tensile Strength: This material offers a wide range of tensile strength, typically from 400 MPa to over 900 MPa.

- Example: The QT500-7 grade has a tensile strength of over 500 MPa, which is several times higher than that of common gray cast iron.

- Elongation: This metric measures the material’s ductility and can range from 2% to over 25%.

- Example: The QT400-18 grade has an impressive elongation of 18%, while the high-strength QT800-2 grade has a lower elongation of around 2%.

- Yield Strength: This indicates the stress a material can withstand before permanent deformation occurs.

- Example: The QT500-7 grade has a yield strength of approximately 320 MPa, ensuring its reliability under load.

Ductile Iron Grades

Ductile iron’s grades are the most direct way to measure its performance, with each grade representing a specific level of mechanical properties. The following table provides a comparison of common grades.

| Grade (ISO) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Brinell Hardness (HBW) | Key Characteristics |

| QT350-22 | ≥350 | ≥220 | ≥22 | ≤150 | Extremely high toughness, for impact-resistant parts |

| QT400-18 | ≥400 | ≥250 | ≥18 | ≤170 | High ductility and toughness, good for impact loads |

| QT450-10 | ≥450 | ≥280 | ≥10 | ≤187 | Good all-around performance |

| QT500-7 | ≥500 | ≥320 | ≥7 | 170-230 | Balanced strength and ductility, most widely used |

| QT550-5 | ≥550 | ≥340 | ≥5 | 180-250 | Improved strength with good toughness |

| QT600-3 | ≥600 | ≥370 | ≥3 | 190-270 | Higher strength, good wear resistance |

| QT700-2 | ≥700 | ≥420 | ≥2 | 210-290 | High strength, used for critical components |

| QT750-5 | ≥750 | ≥450 | ≥5 | 220-300 | Combines high strength and good toughness |

| QT800-2 | ≥800 | ≥500 | ≥2 | 240-300 | Very high strength, excellent wear resistance |

| QT900-2 | ≥900 | ≥600 | ≥2 | 270-350 | Highest strength, for heavy-duty and abrasive environments |

Source: ISO 1083 International Standard

What Is Ductile Iron Made Of?

Ductile iron is produced through a process called spheroidization treatment. This involves adding a small amount of a spheroidizing agent (such as magnesium or rare earth elements) to the molten iron. This chemical reaction forces the carbon to crystallize as spherical graphite during solidification, which is the crucial step for achieving its unique properties.

What Are the Uses of Ductile Iron?

Ductile iron is a versatile material used across various industries, including:

- Automotive Industry: Crankshafts, connecting rods, cylinder blocks, and differential housings.

- Mechanical Engineering: Valves, pump casings, gears, and bearing housings.

- Agricultural Machinery: Tractor parts and other farm implements.

Frequently Asked Questions

What Is the Difference Between Ductile and Cast Iron?

The primary difference between ductile and conventional cast iron (gray cast iron) is their microstructure. Ductile iron’s nodular graphite makes it strong and ductile, while gray cast iron’s flake graphite makes it brittle and weak in tension. For a more detailed comparison of these two materials, read our full article here.

Ductile Iron vs. Steel

While some steels are stronger, ductile iron offers a superior combination of strength, castability, and lower cost, making it a viable alternative to cast steel and forgings in many applications.

What Is Ductile Iron Pipe?

Ductile iron pipes (DI Pipe or DICL Pipe) are a leading application for this material due to their exceptional properties. Because of their high tensile strength, resistance to corrosion, and durability, ductile iron pipes are widely used for water, natural gas, and sewage pipelines.

Contact Us to Get Professional Casting Solutions

We hope this article has helped you better understand ductile iron.

If you have questions about material selection, process optimization, or any casting project, feel free to contact us. Leveraging our deep metallurgical knowledge and extensive project experience, we’ll provide professional solutions and reliable technical support to ensure your project’s success.