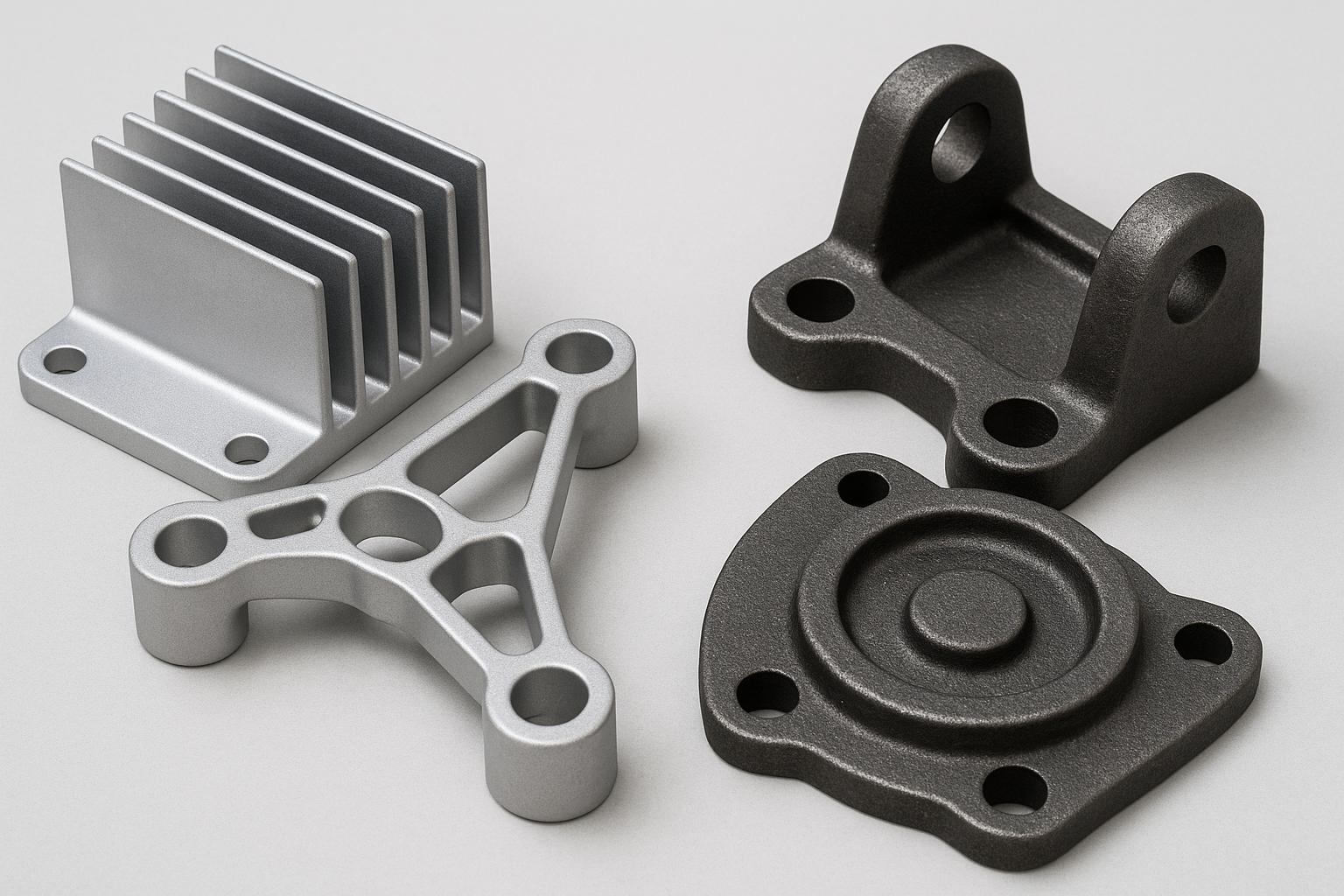

Cast iron and cast steel are two fundamental and important materials in the casting industry. While they both have iron as their main component, they have significant differences in their physical properties and final applications due to variations in their carbon content and manufacturing processes. Understanding these differences is crucial for selecting the right material for any engineering project.

What Are Cast Iron and Cast Steel?

Cast Iron is an iron-carbon alloy with a carbon content typically ranging from 2.11% to 4.0%. This high carbon content gives it excellent castability, allowing it to melt at a lower temperature and easily flow into complex molds. Cast iron’s advantages are high compressive strength and good vibration dampening, but its disadvantages are poor toughness and ductility, making it prone to brittle fracture.

Cast Steel is an iron-carbon alloy with a carbon content typically ranging from 0.05% to 2.11%. Compared to cast iron, cast steel’s lower carbon content gives it greater toughness, ductility, and impact resistance. Cast steel has a higher melting point and a more complex casting process, but its overall mechanical properties are far superior to cast iron.

Main Types of Cast Iron

Cast iron can be classified into several types based on the morphology of graphite in its microstructure, with each type offering unique properties:

- Gray Cast Iron: Graphite appears as flakes. It has low toughness but excellent vibration dampening and machinability. It is commonly used for machine beds and engine blocks.

- Ductile Iron: Graphite is in the form of spheres or nodules. This significantly increases its toughness and strength, making it one of the most widely used types of cast iron for automotive parts and pipes.

- Malleable Iron: Produced by heat-treating white cast iron, its graphite is in the form of irregular clumps. It has good toughness and plasticity, and is often used for pipe fittings and agricultural machinery.

- Compacted Graphite Iron: The graphite is in a vermicular or worm-like shape, giving it properties that are a hybrid of gray and ductile iron. It combines excellent vibration dampening with high strength, and is often used for diesel engine blocks and exhaust manifolds.

Main Types of Cast Steel

Cast steel can also be categorized into different types based on its alloy content and properties:

- Carbon Steel Casting: The main components are iron and carbon. It is used to produce parts that require high strength and toughness.

- Low Alloy Steel Casting: Contains small amounts of alloying elements like manganese, chromium, and molybdenum to further improve strength and wear resistance. It is suitable for heavy machinery and structural components.

- High Alloy Steel Casting: Contains a large percentage of alloying elements, providing superior corrosion, heat, and wear resistance. It is often used in the chemical, energy, and aerospace industries.

- Martensitic Steel Casting: Achieves high hardness and strength through heat treatment but has poor weldability. It is commonly used for water turbine parts.

- Austenitic Steel Casting: Offers excellent corrosion and heat resistance, and is non-magnetic, making it an ideal choice for chemical equipment and cryogenic components.

- Precipitation-Hardening Steel Casting: Achieves extremely high strength and toughness through special heat treatment, and is often used in the aerospace industry.

Core Performance Comparison

| Performance Metric | Cast Iron | Cast Steel |

| Toughness & Impact Resistance | Poor | Excellent |

| Compressive Strength | Excellent | Excellent |

| Castability | Excellent (for complex parts) | Good (high shrinkage, prone to defects) |

| Weldability | Poor | Excellent |

| Machinability | Good | Poor |

| Cost | Lower | Higher |

Toughness and Impact Resistance

This is the most significant difference between cast iron and cast steel. Cast steel, with its low carbon and uniform microstructure, possesses exceptional toughness, allowing it to withstand powerful impacts and dynamic loads. Cast iron, due to its internal graphite structure, has poor toughness and is prone to brittle fracture upon severe impact.

Compressive Strength

In this regard, cast iron excels. It can withstand extremely high static compressive loads, making it an ideal material for supporting heavy structures. Cast steel also has excellent compressive strength but is generally slightly less effective than cast iron at the same weight.

Castability

Cast iron, with its high carbon content, has excellent fluidity, allowing it to be easily cast into parts with intricate details and internal channels, which significantly reduces manufacturing costs. Cast steel has a higher melting point and greater shrinkage, making it more prone to defects like shrinkage porosity during casting, which requires more stringent process control.

Weldability

Cast steel has excellent weldability, making it easy to weld, assemble, and repair. In contrast, cast iron has very poor weldability and is susceptible to cracking from thermal stress during welding, making repairs difficult.

Machinability

Due to the self-lubricating effect of its internal graphite, cast iron has good machinability and is easy to work with. Cast steel is relatively more difficult to machine and requires harder tooling.

Cost

Due to differences in raw materials and manufacturing processes, the production cost of cast iron is typically lower than that of cast steel. Therefore, cast iron can be a more economical choice when performance requirements are met.

Typical Application Scenarios

Due to their differences in properties, these two materials are used in different fields:

Applications for Cast Iron

Primarily used in situations that require high compressive strength and vibration dampening but are not subject to heavy impact. Typical products include machine bases, engine blocks, heavy machinery frames, manhole covers, water pipes, and valve bodies.

Applications for Cast Steel

Often used for critical components that require high toughness, impact resistance, and weldability. Typical products include excavator bucket teeth, crane hooks, wind turbine hubs, bridge components, and pressure vessels.

Conclusion

Simply put, if you need a component that can withstand a large static load but will not be subjected to heavy impact, cast iron may be a more cost-effective choice. However, if you need a part that can withstand impact, tension, and extreme stress, cast steel is irreplaceable. Making the right material choice is crucial for ensuring the success and safety of your project.

Ready to make the right material choice for your project? Contact our expert team today for a free consultation and quote. We’re here to help you cast your vision into reality.