Does Stainless Steel Rust?

Stainless steel is corrosion-resistant but not corrosion-proof. Its passive chromium-oxide film can fail under chlorides,…

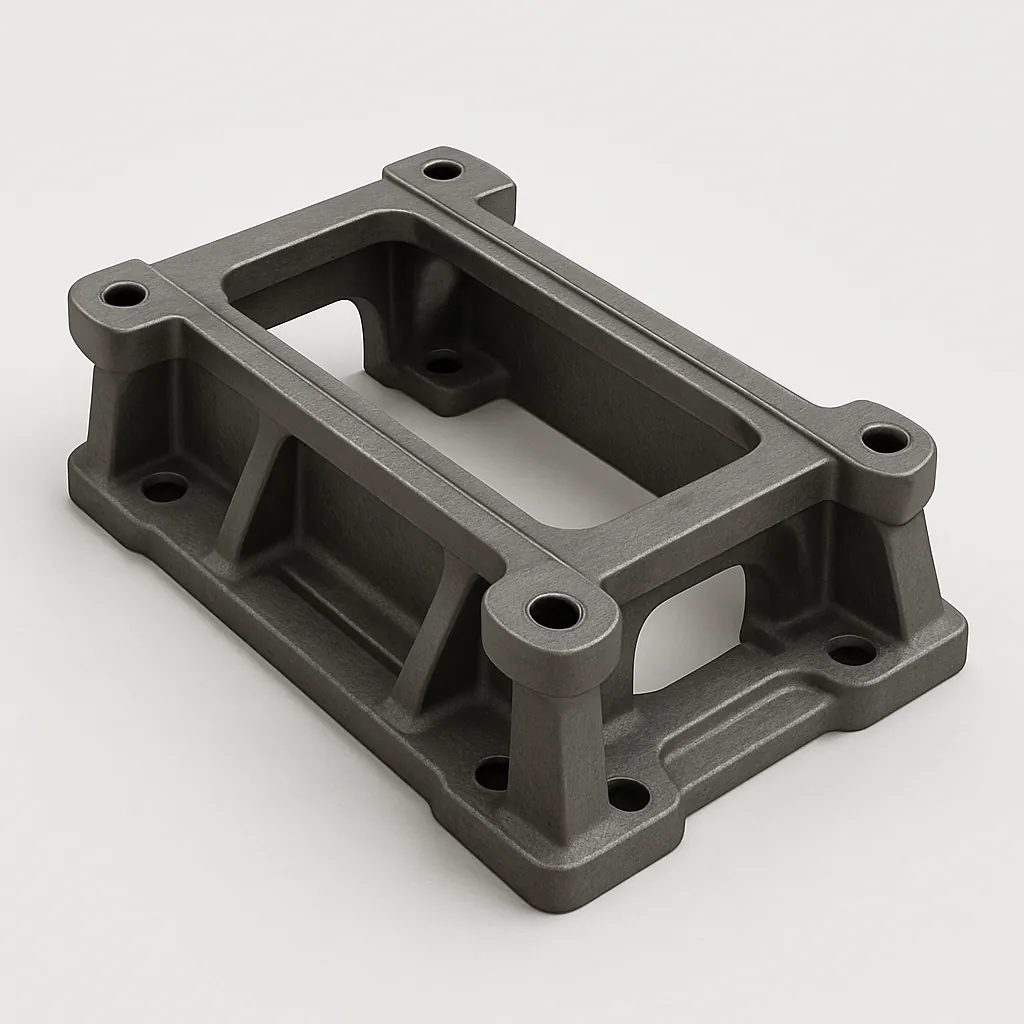

Durable and high-strength steel castings for demanding applications. Suitable for construction, mining, and heavy industrial components. ISO 9001 certified, ±0.05mm tolerance, heat-treated if required.

Over two decades of expertise in producing high-strength steel castings — engineered for performance in the world’s toughest environments.

Our steel castings are built for impact resistance, load-bearing applications, and long-term service life — ideal for construction, mining, and heavy equipment. .

We offer a wide range of steel grades, including carbon steel, alloy steel, and stainless steel — customized for your mechanical and corrosion requirements. .

From low-volume prototypes to high-volume production, we support rapid development with lead times as short as 10 days. .

Each casting undergoes dimensional checks, non-destructive testing (NDT), and material certification to ensure reliability under critical conditions. .

From mold design to final inspection, our steel casting process ensures structural integrity and performance under the most demanding conditions.

Custom molds are created using CAD and simulation tools to ensure proper solidification and casting precision for steel parts. .

We melt steel in induction or arc furnaces and pour into sand or investment molds — ensuring material consistency and metallurgical quality. .

Parts are heat-treated to improve strength, toughness, or wear resistance, followed by CNC machining for precise dimensional control. .

Each casting undergoes NDT (such as UT/RT/MT), surface cleaning, and final inspection to meet functional and cosmetic requirements. .

We provide custom steel casting services to meet demanding industrial applications — from wear-resistant components to large structural parts.

| Specification | Details |

|---|---|

| Casting Weight Range | 1 kg – 500 kg |

| Typical Materials | Carbon Steel, Alloy Steel, Stainless Steel |

| Annual Capacity | 100,000+ parts |

| Machining Tolerance | ±0.1 mm (after heat treatment) |

| Tooling Lead Time | 20–35 days |

We use a range of steel casting routes to match different part sizes and requirements.

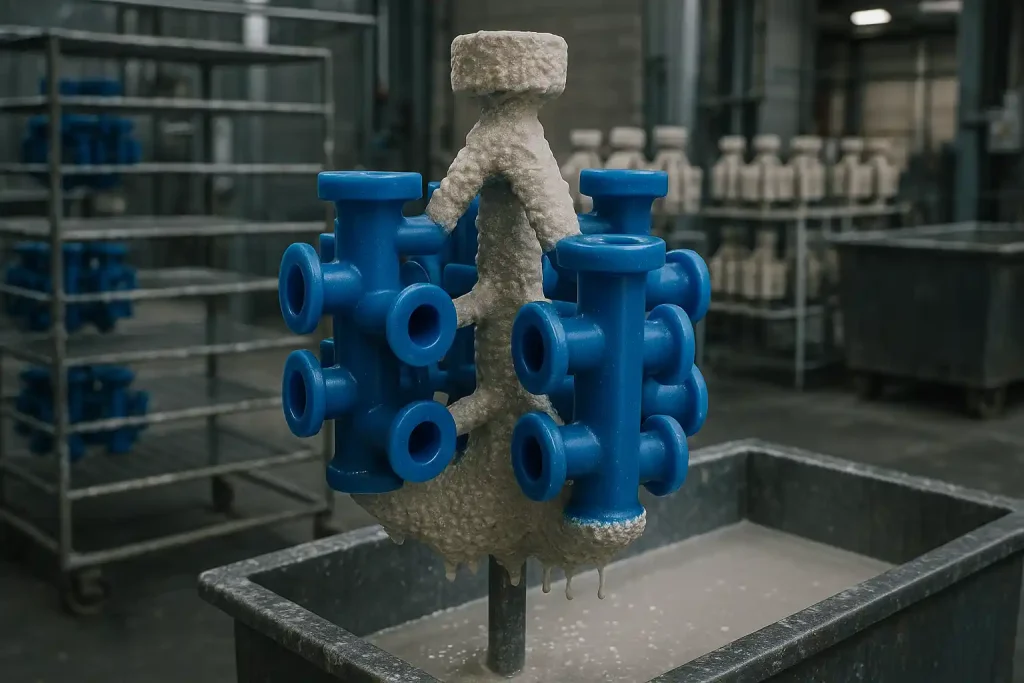

Investment casting, sand casting, and centrifugal casting are our core processes, supported by shell molding, core making, heat treatment, and finish machining as needed.

Precision steel investment casting enables intricate shapes with tight tolerances and smooth surface finish, ideal for complex pump, valve, and machinery components.

It supports alloy steels and stainless grades such as CF8M, CF3M, 17-4PH, and heat-resistant tool steels.

Steel sand casting allows large and heavy-duty industrial components with reliable mechanical strength.

Common grades include WCB, LCB for pressure parts, and WC6 for high-temperature steam service.

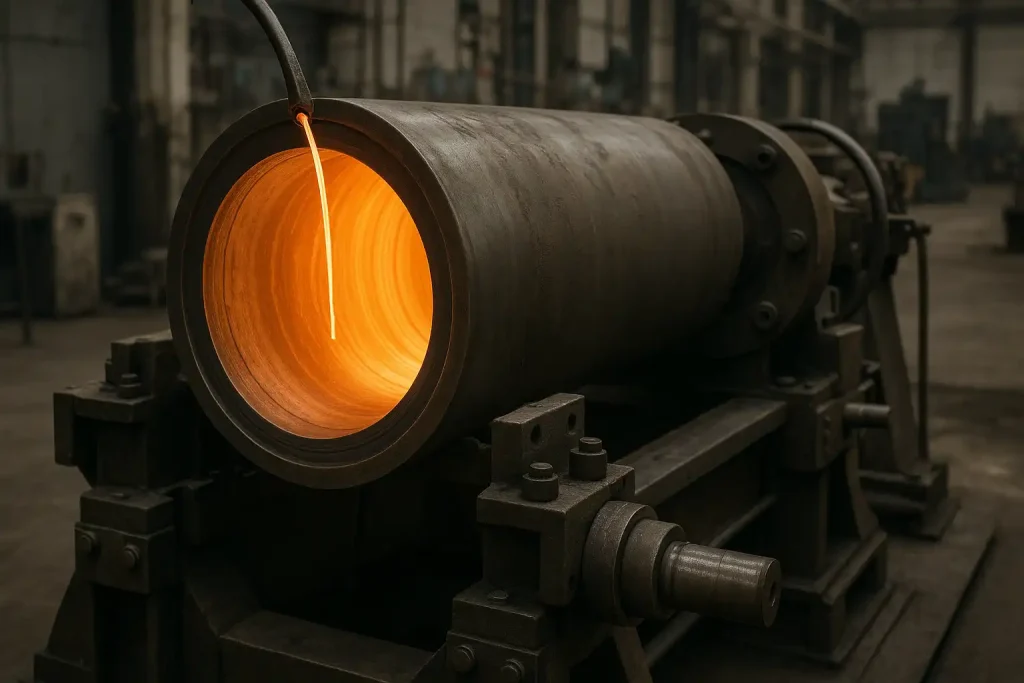

Centrifugal steel casting produces highly dense, defect-free ring-shaped parts with superior wear and pressure resistance.

Typical materials include high-alloy and stainless steels for pump sleeves, bearing rings, and turbine components.

We cast carbon steel, low-temperature steel, alloy steel, and stainless steel for critical industrial use. These materials are selected for pressure-retaining components, corrosion-resistant parts, and high-temperature service in valves, pumps, turbines, and pipeline systems.

The grades below represent widely used steels that offer a reliable balance of strength, impact resistance, weldability, and corrosion performance for demanding applications.

| Steel Grade | Key Properties | Typical Applications | Example Parts |

|---|---|---|---|

| ASTM A216 WCB | Carbon steel casting for high-temperature service with good strength and toughness after normalizing and tempering. Good weldability for general-purpose pressure components. | Valve and pump bodies, flanges and fittings in oil & gas, power generation and industrial piping systems. | Gate Valve Body, Pump Casing, Pipe Flange |

| ASTM A352 LCB | Low-temperature carbon steel casting with strong notch toughness down to −46 °C. Retains impact resistance in cryogenic and cold environments. | Low-temperature valves and pumps, LNG equipment, refrigeration and cold-climate piping components. | Cryogenic Valve Body, LNG Pump Housing, LT Flange |

| ASTM A217 WC6 | Cr-Mo low-alloy steel casting with high strength and creep resistance at elevated temperature. Excellent thermal fatigue resistance for long-term pressure service. | Steam valves, boiler parts and turbine components in power and petrochemical applications. | Steam Valve Body, Stop Valve Bonnet, Turbine Casing |

| ASTM A351 CF8M | Austenitic stainless casting equivalent to 316 with excellent corrosion resistance and weldability. Suitable for chemical, food and marine environments. | Corrosion-resistant valves, pumps, sanitary equipment and marine hardware. | Stainless Valve Body, Pump Impeller, Sanitary Fitting |

| ASTM A351 CF3M | Low-carbon 316 stainless casting grade with superior weld corrosion resistance and low sensitization risk. Ideal for welded components in corrosive service. | Welded piping components, corrosion-resistant tanks and pressure parts requiring reliable weld performance. | Welded Valve Body, Pump Casing, Piping Spool |

Stainless steel is corrosion-resistant but not corrosion-proof. Its passive chromium-oxide film can fail under chlorides,…

This comprehensive guide breaks down the six major types of stainless steel and 43 common…

What’s the difference between stainless steel and carbon steel? This article provides a detailed comparison…