What Is Ductile Iron? Understand Its Properties, Composition, and Uses in One Article

Explore the world of ductile iron. This article provides a comprehensive analysis of its unique…

Durable and high-strength steel castings for demanding applications. Suitable for construction, mining, and heavy industrial components. ISO 9001 certified, ±0.05mm tolerance, heat-treated if required.

Over 20 years of experience in producing durable and precision cast iron components — trusted by industries worldwide.

Our cast iron parts are designed for load-bearing, vibration-damping, and wear-resistant applications — ideal for construction and heavy machinery. .

We offer both gray iron and ductile iron grades (HT200, QT450, QT500) to meet varied mechanical and performance needs. .

Standard lead times from 15 to 30 days. We support small batch prototyping and fast production turnaround. .

All parts undergo dimensional checks, NDT (UT/RT/MT), and material testing to ensure structural integrity and consistency. .

From mold design to final inspection, our cast iron process ensures durability, dimensional accuracy, and cost-efficiency across all applications.

Custom sand or resin molds are designed using CAD and simulation tools to optimize solidification and reduce internal defects in iron castings. .

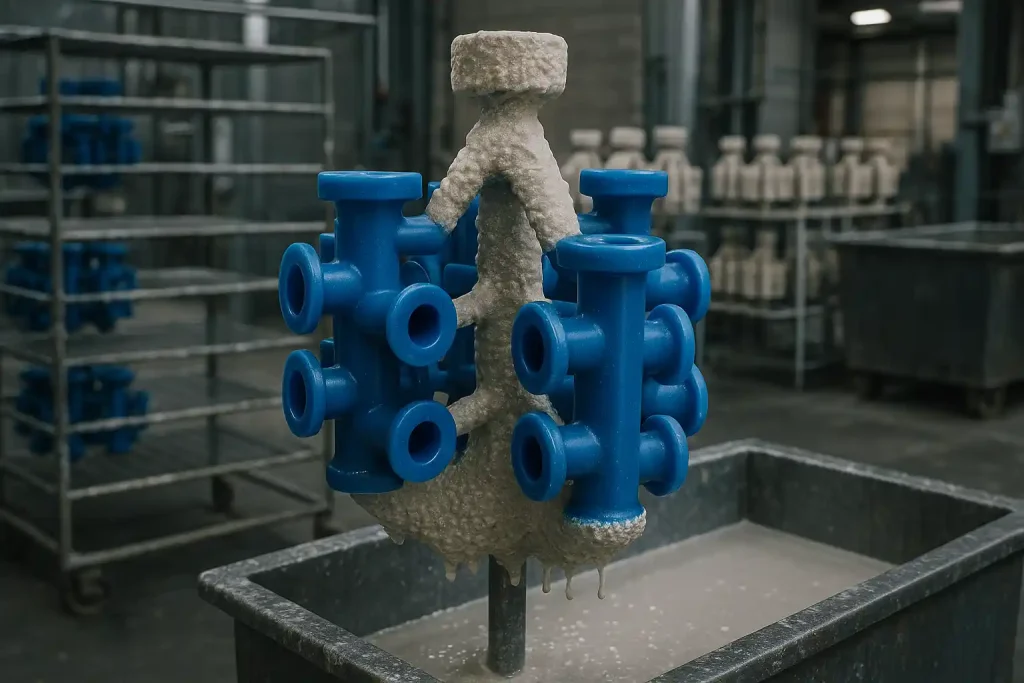

We melt gray or ductile iron in cupola or induction furnaces and pour into preheated molds — ensuring metallurgical stability and clean castings. .

After controlled cooling, castings undergo shakeout, sand removal, and rough cleaning to prepare for further processing. .

Each part is inspected for dimensional accuracy and defects. Optional machining or surface treatment is applied based on final use. .

We provide custom iron casting services to support a wide range of industrial needs — from durable gray iron to high-strength ductile iron components.

| Specification | Details |

|---|---|

| Casting Weight Range | 0.5 kg – 800 kg |

| Typical Materials | Gray Iron (HT200), Ductile Iron (QT450, QT500) |

| Annual Capacity | 150,000+ parts |

| Machining Tolerance | ±0.2 mm (after stress relief or annealing) |

| Tooling Lead Time | 15–30 days |

We use a range of iron casting routes to match different part sizes, shapes, and performance requirements.

Sand casting, shell molding, and ductile iron casting are our core processes, supported by core making, heat treatment, and final machining as needed.

This flexible approach allows us to deliver reliable structural parts for industrial machinery, fluid handling systems, and high-wear applications.

Sand casting is the most common production route for gray and ductile iron parts, allowing large, complex, and heavy components at low cost.

It is ideal for machine bases, pump bodies, housings, automotive components, and general engineering parts.

Shell molding provides superior dimensional accuracy and surface quality for iron castings, especially thin-walled or intricate shapes.

It is widely used for precision gears, automotive castings, valve bodies, and high-volume industrial components.

Ductile iron casting offers high strength, excellent shock resistance, and good elongation, making it suitable for structural parts.

Common applications include valves, hydraulic components, crankshafts, hubs, pump impellers, and pressure-bearing equipment.

We supply gray and ductile iron grades engineered for structural strength, vibration resistance, and wear performance in industrial machinery, pumps, hydraulics, and automotive applications.

The following grades are common choices offering reliable strength, impact toughness, and machinability for cost-effective, long-service components.

| Iron Grade | Key Properties | Typical Applications | Example Parts |

|---|---|---|---|

| ASTM A48 Class 30 | Gray cast iron with good damping capacity and machinability. Offers sufficient strength for lightly-loaded structural components. | Machine bases, housings, compressor covers, and general industrial components. | Lathe Bed, Compressor Housing, Pump Cover |

| ASTM A48 Class 40 | Higher-strength gray iron with better wear resistance and hardness. Suitable for components requiring dimensional stability and vibration control. | Gear housings, brake components, engine blocks, and friction parts. | Gearbox Housing, Brake Drum, Machine Frame |

| ASTM A536 65-45-12 | Ductile (nodular) cast iron offering good ductility, moderate strength, impact resistance and weldability. Excellent fatigue performance. | Automotive suspension, pressure-bearing parts, and industrial machinery components. | Suspension Arm, Flange, Pressure Housing |

| ASTM A536 80-55-06 | Higher-strength ductile iron with improved hardness and wear resistance, suitable for medium-stress mechanical components. | Hydraulic parts, gears, hubs, and rotating machinery elements. | Gear Hub, Hydraulic Body, Pump Impeller |

| ASTM A536 100-70-03 | High-strength ductile iron with excellent tensile strength and fatigue resistance, suitable for high-load structural and safety-critical applications. | Heavy-duty shafts, crank components, lifting equipment, and pressure systems. | Crankshaft, Shaft Sleeve, Structural Bracket |

Explore the world of ductile iron. This article provides a comprehensive analysis of its unique…

Compare gray and ductile iron in terms of microstructure, strength, vibration damping, and cost to…

Discover the five main types of cast iron and their unique properties, from gray to…