Aluminum Casting Grades Explained: Which Alloys Are Suitable for Casting?

Cast aluminum grades are specialized alloys designed for mold filling, shrinkage control, and solidification behavior—not…

Durable and high-strength steel castings for demanding applications. Suitable for construction, mining, and heavy industrial components. ISO 9001 certified, ±0.05mm tolerance, heat-treated if required.

An ISO 9001-certified aluminum casting foundry with over 25 years of experience, providing reliable, high-precision custom solutions worldwide.

We ensure every casting meets tight tolerance and smooth surface finish requirements through precision CNC machining and strict process control. .

Choose from a wide selection of alloys, including A356, ADC12, 6061, and more — tailored for automotive, aerospace, and industrial uses. .

Quick response for new projects: samples in 7 days, mass production in 15–30 days — always on schedule. .

ISO 9001-certified system, full-process inspection, and testing with calipers, spectrometers, and 3D metrology equipment. .

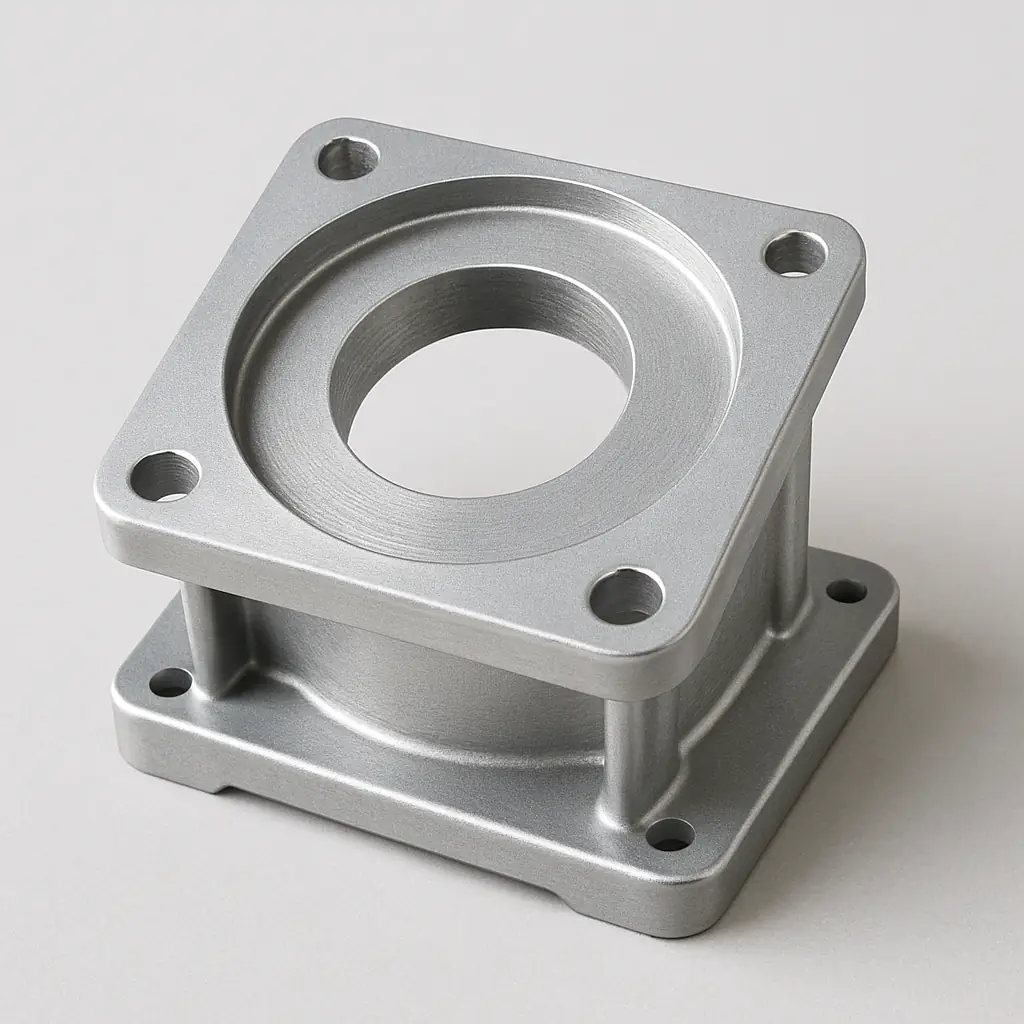

From mold design to final finishing, our aluminum casting process ensures precision and consistency at every stage.

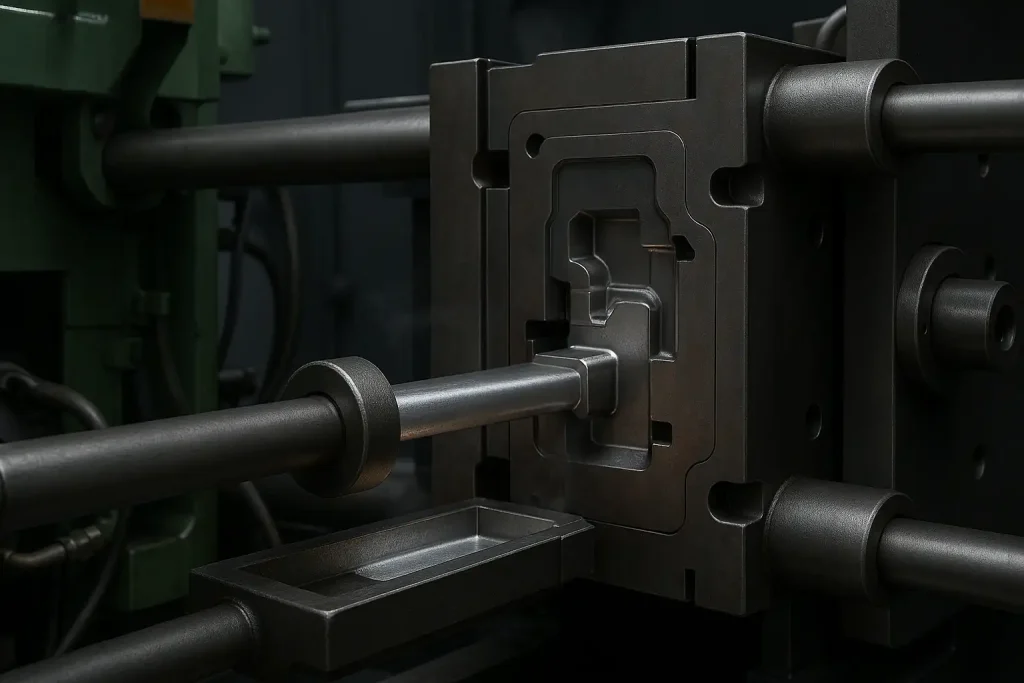

Custom molds are developed using CAD software to ensure accurate geometry and casting feasibility. .

We melt and pour high-quality aluminum alloys using gravity or die casting methods for optimal integrity. .

Tight tolerances and smooth finishes are achieved through advanced CNC machining processes. .

Parts undergo surface treatment, full inspection, and quality verification per ISO standards. .

We provide aluminum casting services tailored to your specific requirements — from small precision parts to large industrial components

| Specification | Details |

|---|---|

| Casting Weight Range | 0.05 kg – 30 kg |

| Typical Alloys | ADC12, A356, ZL101 |

| Annual Capacity | 500,000+ parts |

| Machining Tolerance | ±0.05 mm |

| Tooling Lead Time | 15–25 days |

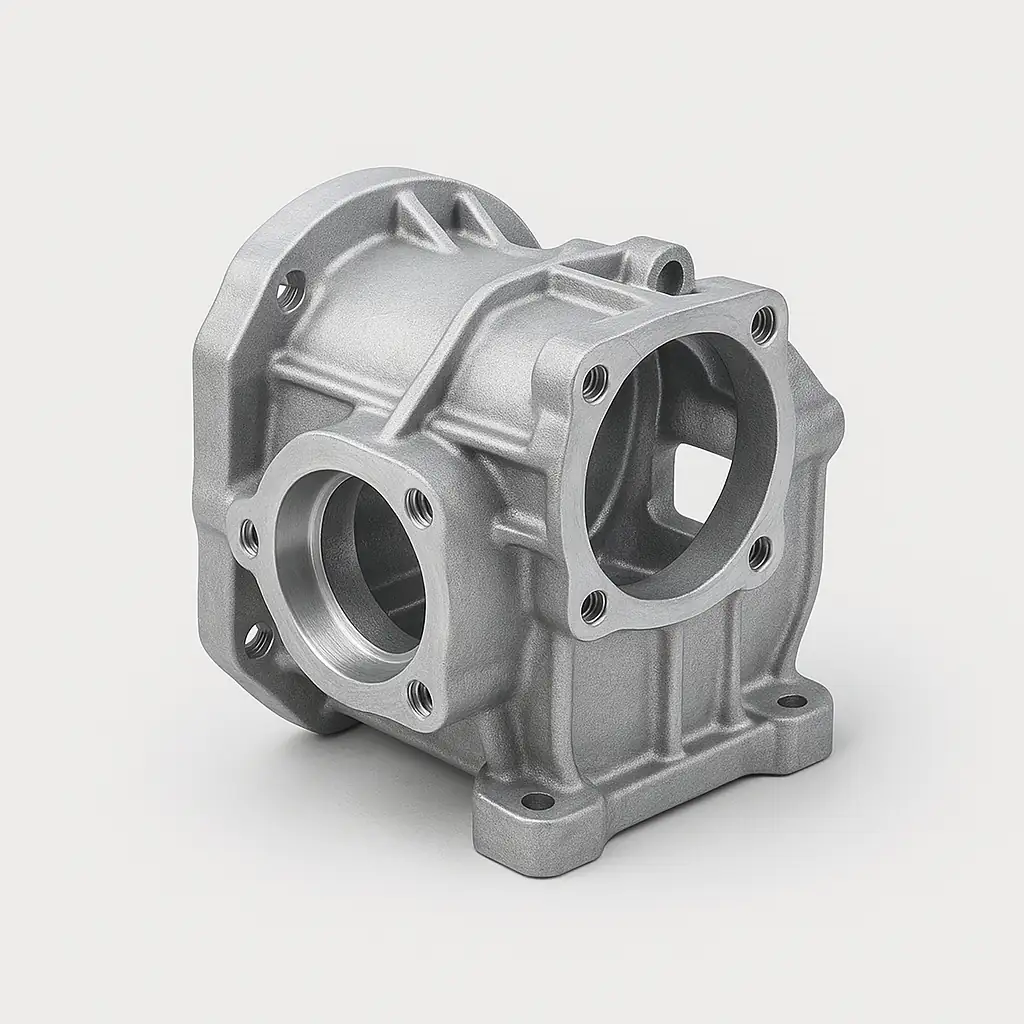

Aluminum die casting enables high-pressure forming of thin-wall, complex geometries with excellent dimensional accuracy and repeatability.

It is ideal for high-volume production and widely used with alloys such as ADC12 and A380.

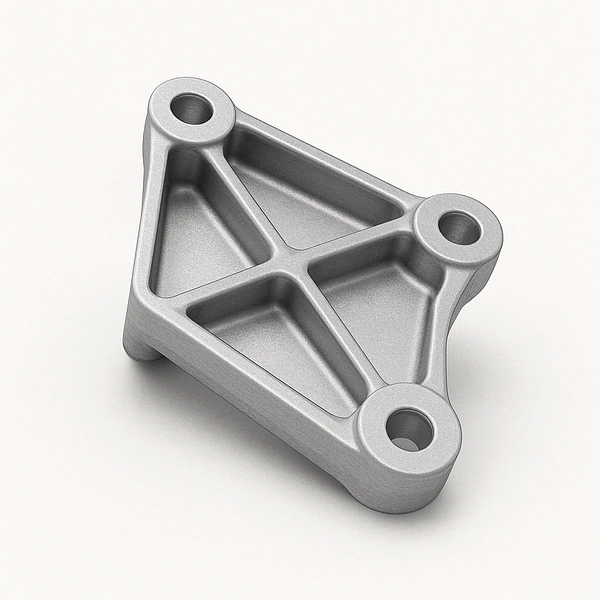

Aluminum gravity casting provides higher mechanical strength and better density than die casting, making it suitable for structural components.

It works well with alloys such as A356 and ZL101, especially when followed by T6 heat treatment.

Aluminum sand casting forms parts by pouring molten aluminum into expendable sand molds.

It supports complex shapes, large components, and cost-efficient low-volume production.

Common alloys include A356, ZL101, and ZL102, making it ideal for prototypes and structural components with thick sections.

| Alloy Grade | Key Properties | Typical Applications | Example Parts |

|---|---|---|---|

| A380 (EN AC-46000) | The most widely used die-casting aluminum alloy, offering a very good balance of castability, mechanical strength and pressure tightness. Good fluidity and dimensional stability for thin-wall, complex housings. | High-volume die-cast housings and covers in automotive, industrial equipment, consumer electronics and power tools. | Transmission Housing, Motor Housing, Gearbox Cover, Tool Body |

| A360 (EN AC-43400) | High-strength die-casting alloy with better corrosion resistance and ductility than A380, and very good fluidity for intricate shapes. Suitable for components exposed to more demanding environments. | Precision automotive and machinery housings, enclosures and brackets that require improved toughness and service life. | Pump Housing, Gearbox Case, Hydraulic Manifold, Sensor Housing |

| A413.0 (EN AC-44200) | High-silicon die-casting alloy with excellent fluidity and pressure tightness. Well suited to thin-wall and leak-critical castings, with good machinability after casting. | Oil and fluid handling components, complex thin-wall housings and high-pressure pump or compressor parts. | Oil Pump Body, Compressor Housing, Thin-wall Cover |

| 383 (EN AC-46100) | Modified A380 alloy with improved fluidity and hot tear resistance. Good strength and pressure tightness, ideal for complex multi-cavity die casting production. | Compact automotive and electronic housings, connectors and brackets where thin-wall filling is critical. | ECU Housing, Connector Body, Small Gearbox, Bracket |

| 390 (High-Silicon Alloy) | Very high silicon content for excellent wear resistance, hardness and dimensional stability at elevated temperature. Lower elongation but exceptional performance in sliding and loaded contact surfaces. | Automotive pistons, compressor and pump components, wear-critical sliding or rotating parts under high load. | Piston, Scroll Compressor Plate, Wear Ring, Pump Rotor |

| A356-T6 (EN AC-42100) | Heat-treatable casting alloy combining high strength, good toughness and very good corrosion resistance. Suitable for gravity casting and permanent mold with T6 heat treatment. | Structural safety-critical components in automotive, aerospace and industrial systems that require low weight and high reliability. | Suspension Control Arm, Wheel Hub, Valve Body, Pump Housing |

| A356 (As-Cast) | Castable Al–Si–Mg alloy with good fluidity and moderate strength in the as-cast condition, offering good weldability and corrosion resistance before heat treatment. | Medium-duty structural castings, fluid handling components and general-purpose gravity cast parts. | Manifold Body, Machine Base, Pump Casing, Structural Bracket |

| G-AlSi7Mg (EN AC-42100) | European gravity-casting alloy equivalent to A356, with good strength-to-weight ratio, excellent corrosion resistance and stable mechanical properties after T6 heat treatment. | Gravity or low-pressure cast components in transportation, hydraulics and general machinery for EU projects. | Hydraulic Housing, Pump Body, Structural Frame, Gear Carrier |

Cast aluminum grades are specialized alloys designed for mold filling, shrinkage control, and solidification behavior—not…

Aluminum does not rust like iron because it contains no iron, but it can corrode…

Learn how to manage tolerances in aluminum castings, from process selection to machining allowances. Practical…