Permanent Mold Casting is a precision casting process that uses reusable metallic molds and gravity pouring to produce high-strength, non-ferrous components. This method, often called gravity die casting, uses durable metal dies to achieve superior mechanical properties and dimensional consistency over long production runs. It is primarily used for medium-volume production of aluminum, magnesium, and copper alloys, offering a balance between casting integrity and cost efficiency.

What Is Permanent Mold Casting

Permanent Mold Casting is a metal-forming technique that utilizes reusable, multi-piece metal dies, relying on gravity to fill the cavity and shape the final part. The designation “Permanent” signifies that the mold—typically constructed from durable cast iron or tool steel—is engineered to withstand repeated thermal cycling, allowing for thousands of casting cycles without being destroyed. Compared to single-use molds like those found in sand or investment casting, the metallic die offers significantly higher durability and consistency. This stability translates directly to superior casting accuracy. The process is primarily optimized for casting aluminum, magnesium, and copper alloys due to their lower melting temperatures.

How the Process Works

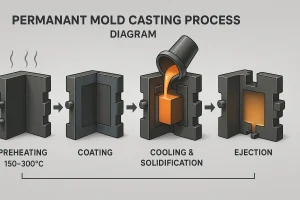

The step-by-step process of permanent mold casting, showing heating, coating, pouring, and solidification stages.

The accuracy and repeatability that characterize permanent mold casting are the result of a stringent, carefully managed multi-stage cycle:

Mold Preparation and Preheating

The cycle begins by ensuring the metallic dies are clean and preheated. Molds are typically raised to a precise operating temperature, often between 150°C and 300°C. This initial step is vital for establishing the thermal stability necessary to control the cooling rate and prevent defects like cold shuts or cracking.

Coating Application

A thin, refractory coating, such as graphite or boron nitride, is applied to the mold’s internal surfaces. This coating serves a dual function: it prevents the molten metal from fusing to the steel die (acting as a release agent) and acts as a thermal barrier to regulate the heat transfer rate, controlling the metal’s solidification speed.

Metal Pouring and Solidification

Molten metal is poured directly into the mold cavity under gravity—external pressure is not typically used. The rapid heat dissipation through the metallic mold initiates fast, directional solidification. The cooling rate, governed by the mold temperature and the applied coating, is the primary factor that dictates the final fine grain structure and mechanical strength of the component.

Mold Opening and Ejection

Once the metal has fully solidified, the mold is opened. The rigid casting is safely removed, often using integrated ejector pins or automated systems. This removal process must be precisely timed to prevent the casting from shrinking onto the die and causing deformation.

Finishing and Trimming

The final stages involve cutting the casting from the gate and riser system and removing any minor flash. The resulting component may then undergo secondary processes, such as heat treatment (like the T6 process for aluminum alloys), to optimize its final mechanical properties, such as hardness and ductility.

Types of Permanent Mold Casting

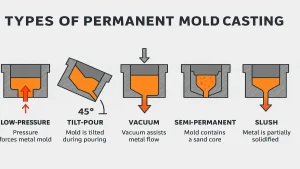

Beyond the standard gravity-pour method, several advanced variations of permanent mold casting have evolved to improve mold filling, reduce defects, and expand the process’s capabilities for complex components. Choosing the right variant is often a key engineering decision based on the part’s complexity and performance requirements.

Infographic comparing five variations of the permanent mold casting process with different pouring and mold configurations.

1. Low-Pressure Permanent Mold (LPPM)

In this variation, molten metal is pushed upward into the die cavity from a sealed crucible under gentle air pressure (usually below 0.7 bar. The controlled, turbulence-free filling minimizes oxidation and porosity, resulting in exceptionally dense and clean castings. This makes it ideal for high-integrity components, such as automotive wheels.

2. Tilt-Pour Permanent Mold

Here, the die is mounted on a tilting mechanism that gradually shifts from horizontal to vertical during pouring. This smooth motion regulates the metal flow rate and minimizes turbulence, reducing air entrapment in thin-walled or large castings that are sensitive to flow discontinuities.

3. Vacuum-Assisted Permanent Mold

Applying a vacuum to the die cavity during the pour actively draws molten metal into intricate sections and simultaneously eliminates trapped gases. The result is a finer microstructure with minimal porosity—an approach highly favored for pressure-tight components and aerospace-grade aluminum alloys where defect levels must be near zero.

4. Semi-Permanent Mold Casting

This hybrid approach combines reusable metal dies with expendable sand cores to create complex internal cavities or undercuts. By using sand for the internal geometry, this technique successfully enables the permanent mold process to handle designs that would otherwise require fully expendable molds, significantly expanding geometric flexibility.

5. Slush Casting

Slush casting is a niche variant in which only the outer layer of the poured metal is allowed to solidify before the remaining liquid metal is poured out. It produces hollow, thin-walled castings with controlled thickness, commonly used for decorative items or very lightweight applications where structural strength is not the primary requirement.

Materials Used in Permanent Mold Casting

The material selection in permanent mold casting is critical, involving three distinct material sets that interact to determine the final product quality and process efficiency:

-

Mold Metals: The dies themselves are fabricated from materials with high thermal fatigue resistance, primarily high-grade cast iron or specialized H13 tool steel. These materials are selected for their resistance to repeated, rapid temperature cycling, ensuring long die life.

-

Casting Alloys: The process excels with non-ferrous metals including aluminum (e.g., A356, 319 series), magnesium, brass, and bronze. The use of these lower-melting-point alloys is crucial for managing the heat load on the metallic dies.

-

Coatings: Refractory coatings, primarily graphite and boron nitride, are essential for both demolding (acting as a release agent) and thermal management. The durability and evenness of these coatings are central to achieving consistent surface quality and extending the metallic die’s service life.

Advantages of Permanent Mold Casting

Permanent mold casting offers several engineering advantages over expendable-mold methods, particularly in mechanical integrity and production consistency:

-

High Mechanical Strength: The metallic mold’s high thermal conductivity accelerates solidification, refining the grain structure and improving mechanical strength, hardness, and wear resistance.

-

Superior Dimensional Accuracy: Rigid steel or iron dies provide excellent repeatability, typically maintaining tolerances around ±0.25 mm with minimal warpage or distortion.

-

Excellent Surface Finish: Smooth cavity surfaces and controlled cooling yield surface roughness values in the range of Ra 3.2–6.3 µm—significantly better than sand castings.

-

Reduced Machining Requirements: Near-net-shape accuracy often eliminates or minimizes post-casting machining, lowering production time and cost per part.

-

High Repeatability: Each die can be reused thousands of times with consistent output, making it suitable for medium- to high-volume production.

-

Improved Metal Integrity: Directional solidification minimizes porosity and shrinkage defects, producing denser, pressure-tight castings.

Limitations of Permanent Mold Casting

Despite its mechanical advantages, permanent mold casting has several key constraints that influence its application suitability:

-

Limited Part Size Range: Large or highly irregular components are impractical due to mold weight, handling limits, and non-uniform cooling behavior.

-

High Tooling Cost: The initial investment for machining and heat-treating the metallic dies is substantial, making the process uneconomical for short runs or prototypes.

-

Material Restrictions: The process is limited mainly to non-ferrous alloys (aluminum, magnesium, copper); ferrous metals cause excessive thermal stress and wear on the dies.

-

Geometric Constraints: Complex internal features and deep undercuts are difficult to produce without expendable cores or hybrid designs.

-

Thermal Fatigue and Maintenance: Continuous heating and cooling cycles gradually degrade die surfaces, requiring regular inspection and re-coating to maintain quality.

When to Use Permanent Mold Casting

Permanent mold casting is an optimal solution for specific production profiles that seek a balance between performance and cost efficiency.

You should consider this process when a project requires medium production volumes, typically ranging from thousands to tens of thousands of parts annually. It is the preferred choice for manufacturing high-strength, high-repeatability components from aluminum, magnesium, or copper alloys. Ideal parts have moderate complexity, relatively uniform wall thickness, and require a better surface quality than sand casting can provide. Conversely, the process is not recommended for prototype production, small batches, components requiring casting of ferrous metals, or parts with highly irregular or massive geometries.

This makes permanent mold casting the ideal choice when strength, repeatability, and surface precision are critical—without the excessive tooling expense of high-pressure die casting.

Applications in Modern Industry

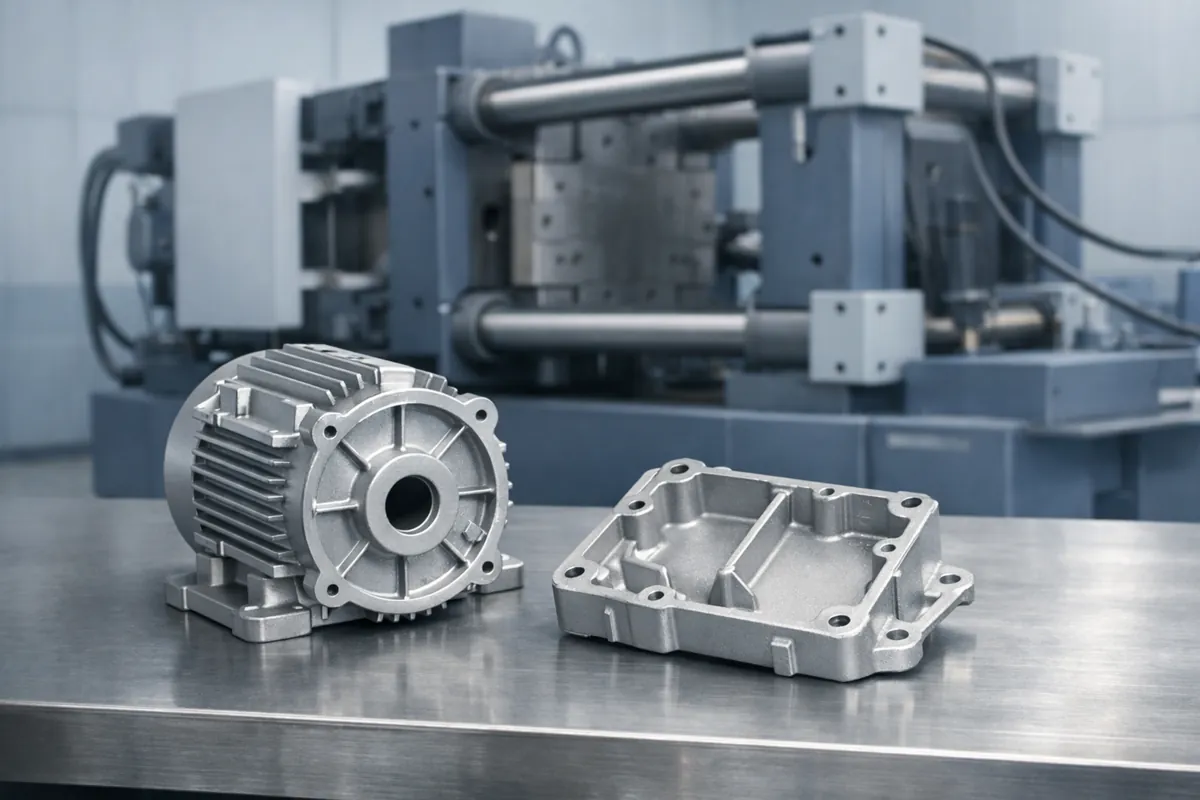

Due to its reliability and superior mechanical properties, permanent mold casting is integral to high-reliability sectors that require strong, non-ferrous components produced at moderate volumes:

-

Automotive: Key applications include high-performance pistons, engine brackets, transmission parts, and brake components where consistent density and strength are paramount.

-

Aerospace & Marine: Used for critical valve bodies, pump housings, and structural fittings that require both a high strength-to-weight ratio and corrosion resistance.

-

Machinery & Electronics: Components such as hydraulic manifolds, specialized gear housings, and durable electrical connector enclosures benefit significantly from the process’s precision and density.

The process excels in applications where a premium is placed on reliable strength, density, and consistency across a stable, moderate production run.

Engineering Outlook

Permanent mold casting maintains its critical position in the manufacturing ecosystem as the go-to solution for high-integrity, medium-scale production. It is successfully positioned as a strong, repeatable alternative that bridges the cost and tolerance gap between low-cost, low-tolerance sand casting and the high-speed, high-cost demands of die casting. Future technological advancements are focused on extending die life through sophisticated coating materials, increasing efficiency via automated pouring systems, and developing hybrid mold systems that integrate expendable cores for greater geometric complexity.

Need engineering-grade permanent mold castings in aluminum or copper alloys? Send us your drawings for a quick DFM check and a reliable quote.