In the vast world of materials science, there exists a type of steel prized for its exceptional hardness and sharpness, widely used in crafting high-end cutlery and medical instruments. But have you ever wondered what gives it such unique properties? This remarkable material, which can resist both corrosion and extreme wear, is what we are about to delve into: martensitic stainless steel.

What is Martensitic Stainless Steel?

Martensitic stainless steel is a type of steel that can be hardened by heat treatment. Unlike the well-known austenitic stainless steel, the core characteristics of martensitic stainless steel are its high hardness, high strength, and magnetic properties. This unique combination of properties, which stems from its specific crystal structure, allows it to perform exceptionally well in applications that require high wear and pressure resistance.

History

The history of martensitic stainless steel dates back to the early 20th century. In 1912, British metallurgist Harry Brearley was looking for a corrosion-resistant material for gun barrels when he discovered that iron alloys with over 12% chromium did not rust easily in air. His further research showed that by adding carbon to the steel and applying a heat treatment, he could create a material that was not only corrosion-resistant but also possessed high hardness and strength. This invention laid the foundation for modern cutlery, surgical instruments, and other industries, heralding a new era for martensitic stainless steel.

Composition

The performance of martensitic stainless steel is determined by its unique chemical composition. Its primary components include:

- Chromium (Cr): Typically ranging from 12% to 18%, this is the main source of the stainless steel’s corrosion resistance.

- Carbon (C): This is the key element for martensitic stainless steel, with a content typically ranging from 0.1% to over 1.0%. It is the high carbon content that allows the material to form a hard martensite phase through heat treatment.

- Other Elements: It may also contain small amounts of manganese (Mn) and silicon (Si) to improve its mechanical and processing properties.

Microstructure

Martensitic stainless steel gets its name from its unique martensitic microstructure. This structure is a non-equilibrium crystal structure that typically forms when the steel is rapidly cooled (quenched) from a high temperature (the austenite phase). During this rapid cooling, carbon atoms do not have enough time to diffuse out and become “trapped” in the iron crystal lattice, forming a special body-centered tetragonal (BCT) structure. It is this highly stressed BCT structure that gives martensitic stainless steel its unparalleled hardness and strength.

Grades

The grades of martensitic stainless steel are primarily classified based on their chemical composition and performance. Here are some of the most common and representative grades:

- Type 420: This is a general-purpose martensitic stainless steel with good polishing properties and corrosion resistance. It can achieve very high hardness after quenching and tempering, while retaining better toughness than grades with a higher carbon content. Type 420 is an ideal choice for making table knives, surgical blades, and scissors.

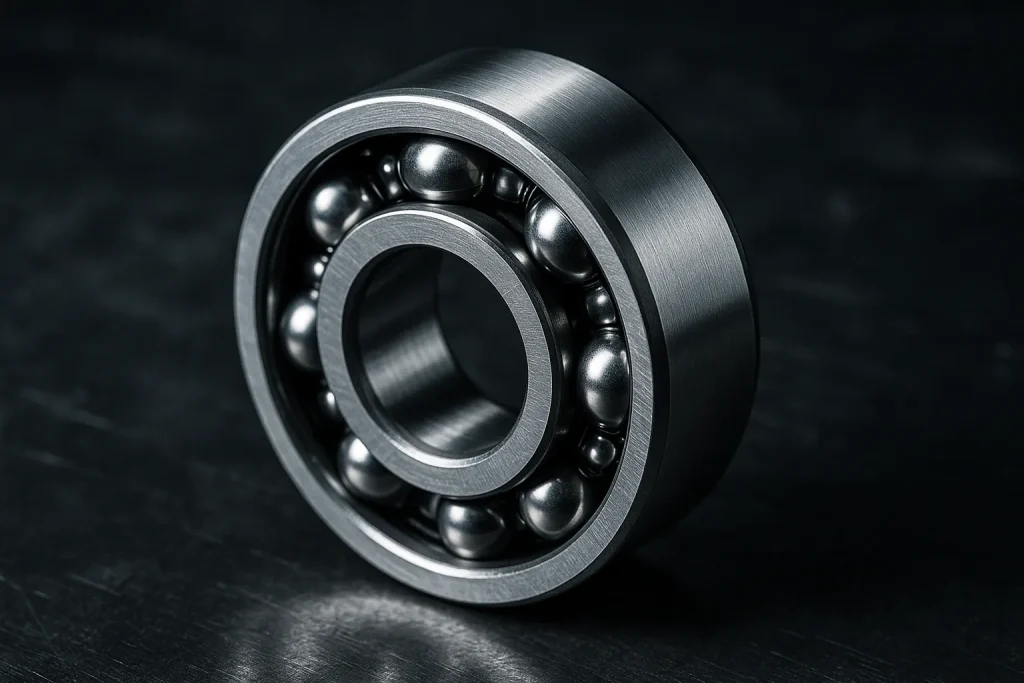

- Type 440C: Type 440C is a “star” among martensitic stainless steels, renowned for its extremely high hardness and strength. It contains a higher proportion of carbon, which allows it to achieve one of the highest hardness levels among all stainless steels after heat treatment. This makes it the preferred material for high-end cutlery, bearings, and valve components.

Properties and Advantages

Martensitic stainless steel stands out among various stainless steel categories due to its unique properties. Its core advantages and key properties include:

- Exceptional Hardness and Strength: This is the most important feature of martensitic stainless steel. Through proper heat treatment (quenching and tempering), its hardness can reach extremely high levels, far exceeding that of austenitic stainless steel. This makes it suitable for manufacturing sharp and durable cutting tools and and mechanical components.

- Excellent Wear Resistance: The high hardness directly translates to outstanding wear resistance. Martensitic stainless steel performs far better than many other types of steel under conditions of prolonged friction and high stress.

- Heat Treatability: This is a key advantage that distinguishes it from austenitic stainless steel. The ability to be heat treated allows its properties to be precisely adjusted to meet specific requirements for hardness and toughness, thereby achieving a perfect balance between strength and toughness.

Disadvantages

Despite its many advantages, martensitic stainless steel also has some inherent disadvantages. It’s crucial to understand these drawbacks to properly select and use this material:

- Relatively Weaker Corrosion Resistance: Compared to austenitic stainless steel, martensitic stainless steel has poorer corrosion resistance. This is because its chromium content is relatively lower, and during the heat treatment process, some chromium combines with carbon to form carbides, which weakens its ability to resist corrosion.

- Brittleness: High hardness and high strength are often accompanied by a certain degree of brittleness. If not properly tempered, martensitic stainless steel can be very brittle and prone to cracking or fracturing under impact or high stress.

- High Welding Difficulty: Due to its high carbon content, martensitic stainless steel is susceptible to cracking in the weld seam and heat-affected zone during the welding process. Therefore, welding usually requires strict preheating and post-weld heat treatment to prevent cracking.

- Cost: Some high-carbon martensitic stainless steels (such as 440C) are relatively more expensive due to their complex manufacturing processes and superior performance.

Applications

Thanks to its high hardness and wear resistance, martensitic stainless steel is widely used in applications with demanding performance requirements. Its main applications include:

- Cutlery: From kitchen knives and chef’s knives to professional hunting knives, martensitic stainless steel is highly favored for its ability to hold a sharp edge.

- Medical Instruments: Surgical scalpels, scissors, and forceps require extremely high hardness and corrosion resistance to ensure sharpness and hygiene.

- Industrial Components: In mechanical parts such as bearings, gears, valves, and turbine blades, martensitic stainless steel can withstand significant wear and pressure, ensuring the long-term stable operation of equipment.

- Springs and Measuring Tools: Its excellent hardness and elasticity make it an ideal material for precision measuring tools and high-strength springs.

Frequently Asked Questions (FAQs)

What is the difference between martensitic and austenitic steel?

The main difference between these two types of stainless steel lies in their crystal structure and hardening method. Martensitic steel has a martensite structure at room temperature and can be hardened by heat treatment (quenching), and it is magnetic. Austenitic steel has an austenite structure at room temperature, cannot be hardened by heat treatment, but can be strengthened by cold working. It is generally non-magnetic.

Is 316 stainless steel austenitic or martensitic?

316 stainless steel is an austenitic stainless steel. It is one of the most well-known grades in the 300 series. It’s a popular choice because it contains molybdenum in addition to chromium and nickel, giving it superior corrosion resistance, especially in chloride environments.

Is martensitic stainless steel FCC or BCC?

The crystal structure of martensitic stainless steel is BCT (Body-Centered Tetragonal). It is neither FCC (Face-Centered Cubic, which belongs to austenite) nor BCC (Body-Centered Cubic, which belongs to ferrite). This unique BCT structure, formed during rapid cooling, is what gives martensitic stainless steel its extremely high hardness.

Is 410 stainless steel martensitic?

Yes, 410 is a classic example of a martensitic stainless steel. It is the most common and widely used martensitic grade, known for its good balance of corrosion resistance and hardness. Like other martensitic steels, it can be hardened by heat treatment and is magnetic.

Conclusion

In conclusion, martensitic stainless steel stands out as a high-performance material due to its unique combination of high hardness, strength, and the ability to be hardened by heat treatment. While its corrosion resistance may not match that of austenitic steel, its unparalleled toughness and wear resistance make it an indispensable choice for demanding applications where durability and sharpness are paramount