Duplex stainless steel is a special type of steel named for its unique dual-phase microstructure: it contains both Austenitic and Ferritic phases, with each crystal phase making up approximately 50%. This precise microstructure is the foundation of duplex stainless steel’s high performance. The ferritic phase provides high strength and resistance to stress corrosion cracking, while the austenitic phase ensures excellent toughness and ductility. This perfect combination allows duplex stainless steel to overcome the limitations of single-phase steels, making it a material that offers both strength and corrosion resistance.

This article provides a comprehensive overview of the properties, types, and applications of duplex stainless steel, and addresses common questions.

Historical Development

The origins of duplex stainless steel can be traced back to the 1930s in Sweden, where it was first developed for use in the sulfite paper industry to resist chloride corrosion. However, its application remained limited due to the smelting technologies of the time. It was not until the 1970s, with the maturation of Argon Oxygen Decarburization (AOD) smelting technology, that researchers were able to precisely control the carbon and nitrogen content in steel. This breakthrough stabilized the ratio of austenite and ferrite, leading to the large-scale production and application of 2205, the second generation of duplex stainless steel. The subsequent development of nitrogen-enhanced super duplex stainless steels (such as 2507) in the 1980s further expanded their use in even more severe environments, making them an indispensable high-performance material in modern industry.

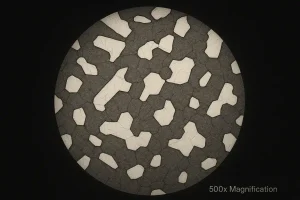

Microstructure

It is composed of both austenitic and ferritic crystal phases, which are typically arranged in alternating strip or island-like structures. The austenitic phase has a face-centered cubic (FCC) structure, while the ferritic phase has a body-centered cubic (BCC) structure. This dual structure combines the advantages of both crystal phases: the grain boundaries of the ferritic phase can effectively stop crack propagation, providing high strength and resistance to stress corrosion cracking. At the same time, the toughness and ductility of the austenitic phase ensure the material’s reliability during processing and use.

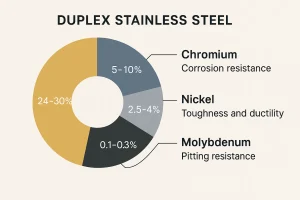

Composition

The following table shows the typical range of key alloying elements for common duplex grades.

| Alloying Element | 2205 (Standard) | 2507 (Super) | 2101 (Lean) | 32760 (Super) |

| Chromium (Cr) | 22% – 23% | 24% – 26% | 21% – 22% | 24% – 26% |

| Nickel (Ni) | 4.5% – 6.5% | 6% – 8% | 1.5% – 2.5% | 6% – 8% |

| Molybdenum (Mo) | 3% – 3.5% | 3% – 5% | 0.1% – 0.8% | 3% – 4% |

| Nitrogen (N) | 0.14% – 0.20% | 0.24% – 0.32% | 0.20% – 0.25% | 0.20% – 0.30% |

| Carbon (C) | ≤0.030% | ≤0.030% | ≤0.030% | ≤0.030% |

| Manganese (Mn) | ≤2% | ≤1.2% | 4% – 6% | – |

| Silicon (Si) | ≤1% | ≤0.8% | – | – |

| Phosphorus (P) | ≤0.03% | ≤0.035% | – | – |

| Copper (Cu) | – | – | 0.1% – 0.8% | 0.5% – 1.0% |

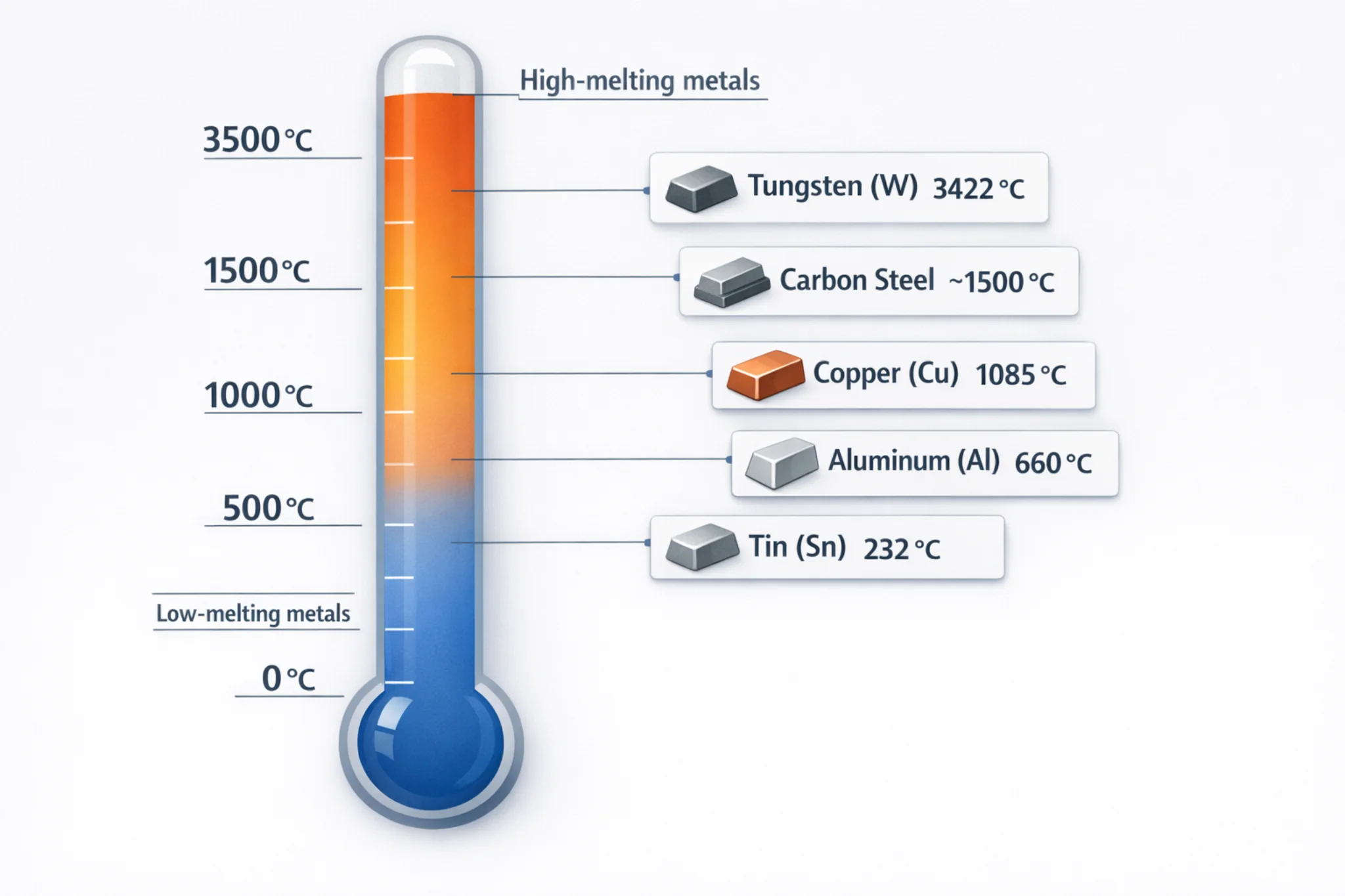

| Tungsten (W) | – | – | – | 0.5% – 1.0% |

Performance

The unique structure of duplex stainless steel gives it superior performance, making it a go-to material for demanding applications. The following table details the specific properties of common duplex stainless steel grades.

| Property | 2205 (Standard Duplex) | 2507 (Super Duplex) | 2101 (Lean Duplex) | 32760 (Super Duplex) |

| Tensile Strength | 620 – 880 MPa | 800 – 1000 MPa | 600 – 850 MPa | 780 – 950 MPa |

| Yield Strength | 450 MPa minimum | 550 MPa minimum | 400 MPa minimum | 550 MPa minimum |

| Corrosion Resistance | Excellent resistance to pitting, crevice, and stress corrosion cracking in chloride environments. | Extremely high resistance to pitting, crevice, and stress corrosion cracking. Superior to 2205. | Comparable to 304L in many environments, with superior stress corrosion cracking resistance. | Exceptional resistance to corrosion and erosion. Used in the most aggressive environments. |

| Toughness | Good, particularly at low temperatures down to -50°C. | Good, with resistance to embrittlement. | Good. | Excellent. |

Types of Duplex Stainless Steel

Duplex stainless steel is not a single material but a family of grades, which are classified into different types based on their alloy content and performance.

- Lean Duplex Steel: These grades reduce the content of expensive nickel and compensate by increasing manganese and nitrogen to maintain performance. A prime example is 2101, which offers a cost-effective solution with good corrosion resistance, often used in architectural and structural applications.

- Standard Duplex Steel: Represented by 2205, this is the most widely used and well-balanced grade, providing an excellent combination of strength and corrosion resistance. It is the go-to choice for most application scenarios.

- Super Duplex Steel: Grades like 2507 and 32760 contain higher levels of chromium, molybdenum, and nitrogen. This makes them extremely strong and corrosion-resistant. They are specifically designed for the most aggressive environments, such as seawater desalination and highly acidic media.

Grades

Duplex stainless steels are available in different grades depending on their corrosion resistance and strength levels. Here are some common duplex stainless steel grades and their applications:

| Grade | Common Name | Key Properties | Typical Applications |

| 2205 | Standard Duplex Steel | Balanced strength and corrosion resistance | Oil and gas, chemical engineering, marine engineering |

| 2507 | Super Duplex Steel | Extremely high corrosion resistance | Seawater desalination, harsh acidic environments |

| 2101 | Lean Duplex Steel | Cost-effective, good corrosion resistance | Construction, light industry |

| 32760 | Super Duplex Steel | Extremely high strength and corrosion resistance | Deep-sea equipment, heat exchangers |

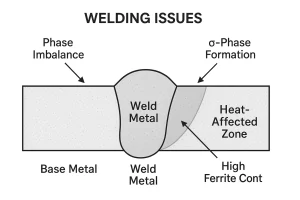

Welding Issues

Welding duplex stainless steel is more complex than welding single-phase stainless steels. The main challenge lies in maintaining the balance of the austenitic and ferritic phases in the weld. If the welding heat cycle is not properly controlled, the following issues can occur:

- Phase Imbalance: The heat from welding can affect the phase balance in the weld seam and the heat-affected zone. Excessive heat input or a rapid cooling rate can lead to an overly high ferritic content, which sacrifices the material’s toughness and corrosion resistance.

- Formation of Deleterious Phases: Prolonged exposure to certain temperature ranges (e.g., between 800°C and 950°C) can cause the formation of brittle intermetallic phases, such as the sigma phase (σ-phase). These deleterious phases can severely reduce the material’s toughness, ductility, and corrosion resistance.

Therefore, welding duplex stainless steel requires strict control over heat input, interpass temperature, and cooling rate. The use of specialized filler materials that closely match the parent metal’s composition is also essential to ensure the weld joint maintains its superior mechanical and corrosion-resistant properties.

Frequently Asked Questions

What is the difference between duplex and 316 stainless steel?

- 316 stainless steel is an austenitic stainless steel with moderate strength and corrosion resistance, but it has poor resistance to stress corrosion cracking.

- Duplex stainless steel (e.g., 2205) has twice the strength of 316 and offers much better resistance to pitting and stress corrosion cracking in chloride environments.

What is the equivalent to duplex 2205 stainless steel?

Internationally, the standard ASTM grade for 2205 is S32205. Its equivalent grades in other countries include China’s 022Cr22Ni5Mo3N and the EU’s 1.4462.

Is 304 a duplex stainless steel?

No, 304 stainless steel is a classic austenitic stainless steel, and its microstructure is almost entirely composed of the austenitic phase.

What is the price per kilogram for duplex stainless steel?

The price of duplex stainless steel is generally higher than common stainless steels (like 304 and 316) because its alloy composition contains more expensive elements such as chromium, molybdenum, and nickel. The specific price depends on the grade, market supply and demand, product form (sheets, pipes, etc.), and the supplier.

Summary

With its superior combination of properties, duplex stainless steel offers unparalleled advantages in tackling complex and demanding industrial challenges. It is not just a material but a testament to the progress of modern engineering technology. Whether you are looking for a material with both high strength and excellent corrosion resistance or the perfect balance between cost-effectiveness and performance, duplex stainless steel is an ideal choice worth considering.

If you have any application needs for duplex stainless steel or require customized solutions, feel free to contact us for professional support and service!