What is a Foundry?

A foundry is a specialized industrial facility that manufactures metal components by pouring molten metal into a mold cavity. The resulting product is known as a casting. Foundries are the foundational source for critical components in global supply chains, ranging from engine blocks and pump bodies to hydraulic manifolds and brake brackets.

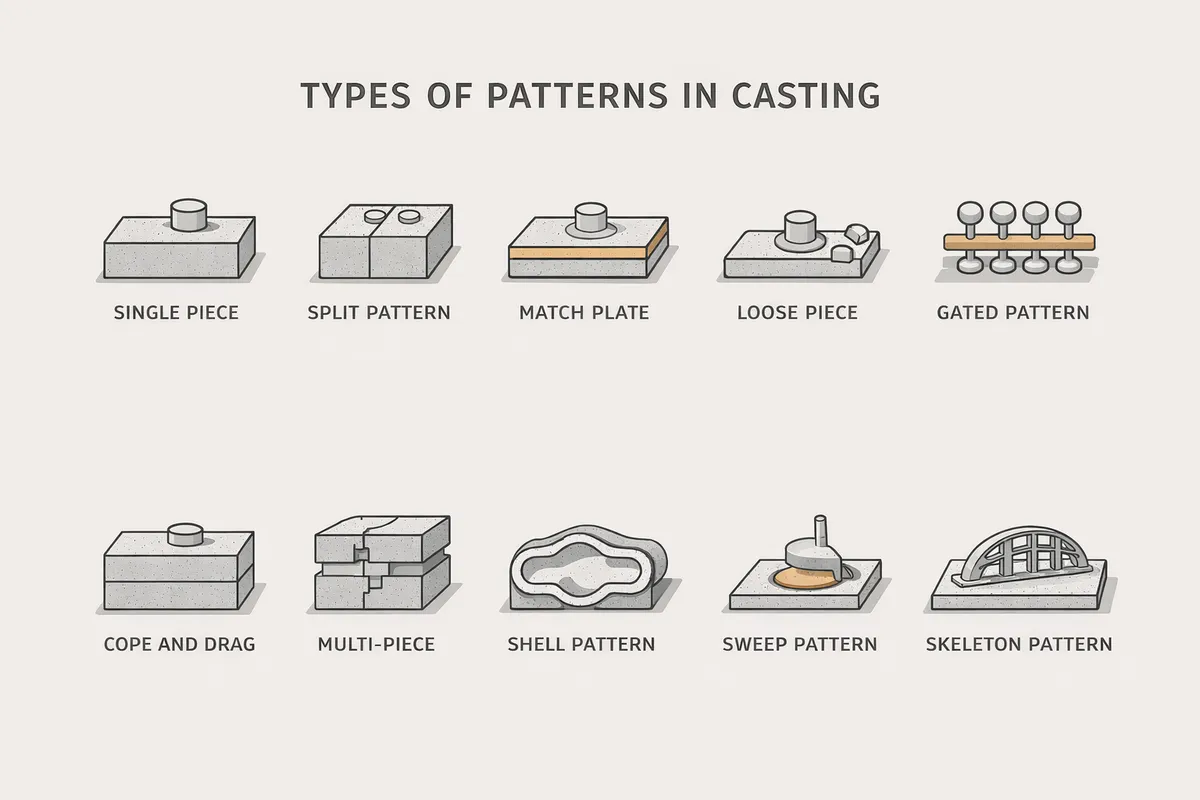

Casting Process

The production of a metal casting is a precise engineering sequence. It begins with molding and core making, where engineers use sand or metal patterns to define the external geometry of the part. If the component requires complex internal passages, sand cores are produced and placed inside the mold to create the hollow structure.

This is followed by melting and metallurgical control. Metal is heated in induction or gas-fired furnaces until it reaches a liquid state. Before pouring, technical teams perform a spectrographic analysis to verify that the chemical composition and temperature strictly meet the required material grade specifications.

During controlled pouring, the molten metal is precisely transferred into the mold. This stage requires rigorous control over temperature and flow rate to prevent casting defects such as porosity or inclusions. The final stage is shakeout and post-processing, where the mold is removed, and the casting undergoes shot blasting, grinding, and heat treatment to achieve its final mechanical properties.

Types of Foundries

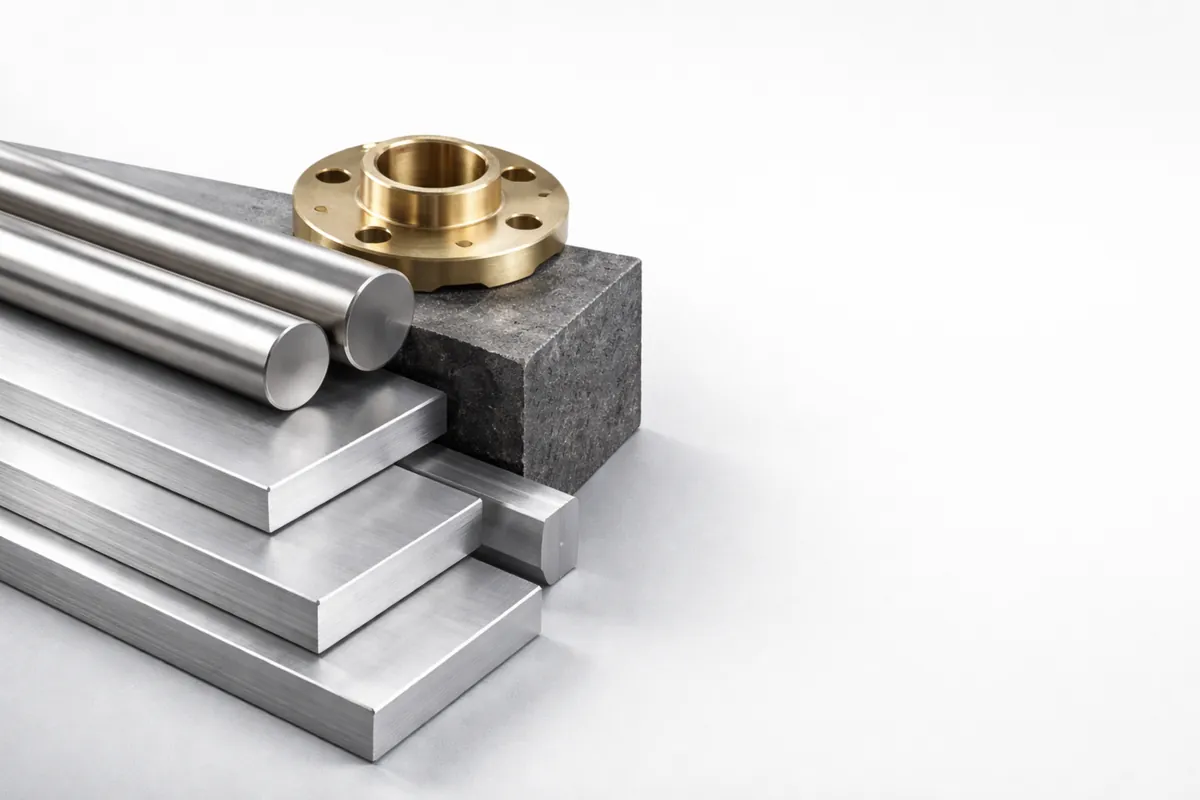

In industrial practice, foundries are typically categorized by their material specialization and forming technology. Ferrous sand casting foundries focus on ductile iron, gray iron, and cast steel for heavy-duty structural parts used in construction and mining.

Alternatively, non-ferrous foundries specialize in alloys such as aluminum, copper, and magnesium. These facilities utilize processes like investment casting or permanent mold casting to provide superior surface finishes and precision, making them ideal for the aerospace and marine industries where weight and corrosion resistance are critical.

Foundry Equipment

Modern foundry operations rely on highly integrated mechanical systems. Within the production facilities, core machinery includes medium-frequency induction furnaces, automated molding lines, and high-efficiency sand mixing systems to ensure metallurgical purity and mold consistency.

To guarantee engineering compliance, facilities also integrate advanced processing and testing tools. This includes automated shot-blasting machines and precision heat-treatment furnaces, as well as spectrometers for chemical analysis and Coordinate Measuring Machines (CMM) for dimensional accuracy. This loop of advanced machinery ensures that every casting meets rigorous technical specifications before leaving the facility.

Foundry Working Environment and Safety

A foundry is a high-risk heavy industrial environment where thermal energy control is the primary safety challenge. The extreme temperatures of molten metal and potential splashes during pouring pose significant risks. Consequently, melting areas must strictly enforce fire protocols and rigorous zone isolation.

Furthermore, environmental health protection is a major focus for modern facilities. Dust from molding and high noise levels are mitigated through high-efficiency dust collection systems and acoustic enclosures. Modern foundries mandate the use of Personal Protective Equipment (PPE) and increasingly introduce automated pouring robots to reduce human exposure to hazardous environments.

Casting vs Machining vs Forging

The unique advantage of casting is its ability to create near-net-shape parts with complex internal geometries and high material utilization. In contrast, machining is a subtractive process used to achieve high-precision tolerances, often as a secondary operation. Forging relies on pressure to reshape metal grains, which enhances fatigue strength but lacks the design flexibility for the intricate shapes that casting provides.

MinHe Foundry Capabilities

As a professional engineering partner, MinHe provides comprehensive support across a wide range of materials, including cast iron, steel, copper, and aluminum. We specialize in delivering custom solutions from raw casting to precision machining. By engaging in Design for Manufacturability (DfM) reviews early in the project, MinHe assists OEM customers in optimizing part structures to reduce total manufacturing costs while maintaining peak performance across all material requirements.