Vacuum casting is a replication technology utilized extensively within product development cycles, specifically for producing high-fidelity parts required for design verification, functional testing, and limited production runs. This methodology bridges the gap between single-unit prototypes derived from additive manufacturing and the high-volume capabilities of mass production tooling.

The process is fundamentally characterized by its use of “soft tooling”—molds made from liquid silicone rubber—to precisely duplicate a master pattern. It is ideally suited for prototype manufacturing and low-volume production where the required quantity typically ranges from 10 to 100 units per mold. It provides parts with excellent surface finish and material properties that closely mimic final production plastics, making it a critical step in understanding replication methods used for pre-series evaluation and validation builds.

This guide provides an engineering-informational overview of the vacuum casting process, focusing on technical parameters, material science, and quality control checkpoints necessary for achieving dimensional accuracy and desired mechanical performance.

What Is Vacuum Casting

Vacuum casting, also known as urethane casting or polyurethane casting, is a manufacturing process based on the principle of using negative pressure to draw liquid casting material into a flexible silicone mold. This technique ensures complete mold fill, preventing air entrapment and bubble formation, which are common issues in atmospheric pressure casting.

The core technology relies on a two-part system: the soft tooling and the casting resin. The silicone mold is an elastomeric tool created by surrounding a master model with liquid silicone and subsequently curing it. This tooling offers high-resolution detail transfer and is economical for small batch runs. The casting material is primarily polyurethane resin (PU resin), a family of polymers chosen for their ability to simulate a wide range of engineering plastics, including ABS, PC, PP, and elastomers. The process is a replication casting method conducted under parameter-controlled vacuum conditions.

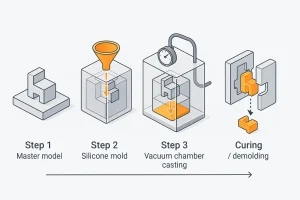

How the Vacuum Casting Process Works

The complete vacuum casting workflow is systematically executed in four critical phases to ensure repeatable results and part quality.

1. Master Model Creation

The quality of the final cast part is directly dependent on the dimensional accuracy and surface finish of the master model. The master model is typically produced using high-resolution additive manufacturing methods (e.g., SLA, PolyJet) or precision CNC machining.

- Dimensional Accuracy: The master model must adhere to the final part’s critical tolerances.

- Surface Preparation: A highly smooth surface finish, often Ra 0.8–1.6 µm, is required, as the silicone mold will replicate every surface detail, including imperfections.

2. Silicone Tooling

The master model is mounted within a casting box, and liquid silicone rubber is poured around it. The entire assembly is placed into a vacuum chamber (≈ 1 kPa (absolute)) to evacuate trapped air bubbles within the liquid silicone.

- Curing: The silicone is cured, often at ≈ 40 °C, to accelerate polymerization.

- Tool Preparation: Once cured, the mold is carefully cut open along a predetermined parting line, and the master model is removed, leaving a cavity ready for casting. A typical mold offers a service life of 20–25 castings before dimensional degradation becomes a critical factor.

3. Resin Preparation and Vacuum Pouring

This phase is executed inside a vacuum casting machine. The two-component polyurethane resin is precisely weighed, mixed under vacuum, and degassed.

- Temperature Control: Both the mold and the resin components are pre-conditioned, usually to ≈ 25–35 °C, to control viscosity and pot life.

- Vacuum Pouring: The mixed resin is introduced into the silicone mold cavity. The entire pouring process is conducted under 1–5 kPa (absolute) to ensure complete filling without air entrapment.

4. Curing and Finishing

After pouring, the filled mold is removed from the vacuum chamber and transferred to a curing oven.

- Post-Cure: A thermal post-cure, typically at 60–80 °C for 2–4 hours, is applied to achieve the final mechanical properties and chemical stability of the PU resin.

- Finishing: Once cured, the part is extracted, and runners, gates, and flash are removed. Standard finishing operations include sanding, painting, or texture application to meet the specified surface finish requirement.

Process Control and Quality Parameters

Process stability and part consistency in vacuum casting rely on stringent parameter-controlled execution. The following table summarizes key engineering checkpoints.

| Parameter Checkpoint | Target Range / Specification | Critical Control Mechanism |

| Vacuum Pressure (Pouring) | 1–5 kPa | High-resolution vacuum gauge, automatic cycle control |

| Mold Temperature (Pouring) | 25–35 °C | Temperature-controlled chamber or preheating plates |

| Cure Temperature (Post-Cure) | 60–80 °C | Calibrated convection oven, monitored cycle time |

| Dimensional Accuracy | ± 0.2 mm (for dimensions ≤ 100 mm) | High-precision master model, minimized shrinkage control |

| Surface Finish | Ra 0.8–3.2 µm | Master model surface quality, silicone mold integrity |

| Material Mixing Ratio | Determined by resin TDS (± 1% mass) | Calibrated mass scale, verifiable process logs |

Materials Used in Vacuum Casting

Master Model Materials

The preferred materials are photopolymers (SLA/DLP) or high-grade engineering plastics (e.g., ABS, POM) if CNC machined. The material must withstand the thermal stress of silicone curing (≈ 40 °C) and possess sufficient stiffness to maintain dimensional stability during the tooling process.

Silicone Mold Properties

The silicone material is a two-component RTV (Room Temperature Vulcanizing) rubber, selected primarily for its tear resistance, flexibility, and heat tolerance. High-quality silicone permits replication of features as small as 0.1 mm. Shrinkage during silicone curing is a critical factor, typically controlled to 0.1–0.3%.

Polyurethane (PU) Resins

The strength of vacuum casting lies in the versatility of polyurethane resins. These materials are formulated to simulate engineering properties, including:

- Rigid Plastics: Simulating ABS (high impact strength, D75–D85 Shore Hardness), PC (transparent, high toughness).

- Elastomers: Simulating rubber or TPE, with hardness ranging from A30 to A90 Shore.

- Specialty Resins: Fire-retardant (UL94-V0), biocompatible (USP Class VI), or high-temperature formulations.

Material Selection Challenges

The primary challenge is achieving the exact mechanical and thermal properties of a production-grade thermoplastic. While PU resins can closely simulate the performance profile, true equivalency is not achievable. Engineers must validate material performance through functional testing on the verification batches.

Advantages and Limitations

| Advantages (Engineering Parameters) | Limitations (Process Constraints) |

| Surface Fidelity: Replicates master model surface finish precisely, down to Ra 0.8 µm. | Dimensional Accuracy: Inherently limited by material shrinkage, typically 0.2–0.5%. |

| Material Flexibility: Vast range of polyurethane resin options to mimic production plastics. | Tool Life: Soft tooling limits production volume to ≈ 20–25 castings per mold. |

| Geometric Complexity: Enables deep undercuts and intricate features with reduced draft requirements. | Part Size: Typically limited by the vacuum machine volume, standard parts ≤ 1000 mm (equipment-dependent). |

| Time-to-Part: Cycle time is optimized for short lead time for validation scale. | Wall Thickness: Thin walls (< 1 mm) and excessively thick sections (> 10 mm) present casting challenges. |

Industrial Applications of Vacuum Casting

Vacuum casting provides a resource-efficient solution across multiple industries requiring high-fidelity prototypes and small-series parts.

- Automotive: Used for interior component mock-ups (dashboards, ventilation components), validation of aesthetic and tactile properties, and pre-series evaluation of low-stress external trim pieces.

- Consumer Electronics: Production of enclosure prototypes requiring excellent surface finish for aesthetic review and fit-and-function verification, often with simulated textures.

- Medical Devices: Creation of detailed, biocompatible prototypes (using specialized resins) for surgical planning models and ergonomic testing of handheld devices prior to expensive hard tooling investment.

- Design Verification: Essential for the final stage of design validation, allowing engineers to test functional assemblies, color, finish, and texture (CF&T) elements before full commitment to mass production tooling.

Comparison with Other Casting Methods

Comparison with Injection Molding

Injection molding is the benchmark for high-volume manufacturing, characterized by high initial tooling costs (hard steel or aluminum) and rapid cycle times. Vacuum casting utilizes low-cost silicone tooling and offers a controlled cycle optimized for low-volume production. The superior dimensional tolerance of injection molding (± 0.05 mm) is traded for the flexibility and low initial investment of vacuum casting for validation batches. Summary: Vacuum casting is the preferred route for pre-series evaluation where tooling expenditure is a primary constraint.

Comparison with 3D Printing (Additive Manufacturing)

Additive manufacturing methods (e.g., FDM, SLA) are superior for single-unit custom parts or design iterations. However, polyurethane resins used in vacuum casting typically offer better thermal, mechanical, and surface characteristics that more closely resemble true production materials. Vacuum casting is inherently a replication process, making it superior for producing verification batches of identical parts with consistent material properties. Summary: Vacuum casting provides enhanced material fidelity and repeatability for batches of 10+ units compared to most additive processes.

Comparison with Centrifugal Casting

Centrifugal casting is primarily used for metals or specific geometric challenges. It relies on rotational force to drive material into the mold. Vacuum casting relies on negative pressure, making it highly effective for ensuring void-free filling of complex geometries using lower-viscosity PU resins. Centrifugal casting is less utilized for simulating engineering plastics. Summary: Vacuum casting is optimized for complex geometries using polyurethane resins under parameter-controlled vacuum conditions, unlike centrifugal casting’s reliance on kinetic force.

Engineering Conclusion

The Vacuum Casting process provides a robust and resource-efficient method for producing high-fidelity, functional parts for pre-series evaluation and limited low-volume production. Achieving consistent quality relies upon rigorous control of process parameters, including vacuum pressure (1–5 kPa), thermal conditioning (25–35 °C), and post-cure cycles (60–80 °C). The controlled application of polyurethane resins within the silicone mold system ensures part consistency and dimensional accuracy within the ± 0.2 mm tolerance range, critical for successful verification batches.

Vacuum casting remains one of the most valuable replication methods for bridging design intent and manufacturability.

Engineers studying prototype validation or soft-tooling techniques can use this process as a benchmark for understanding how casting parameters influence dimensional accuracy, surface quality, and repeatability.