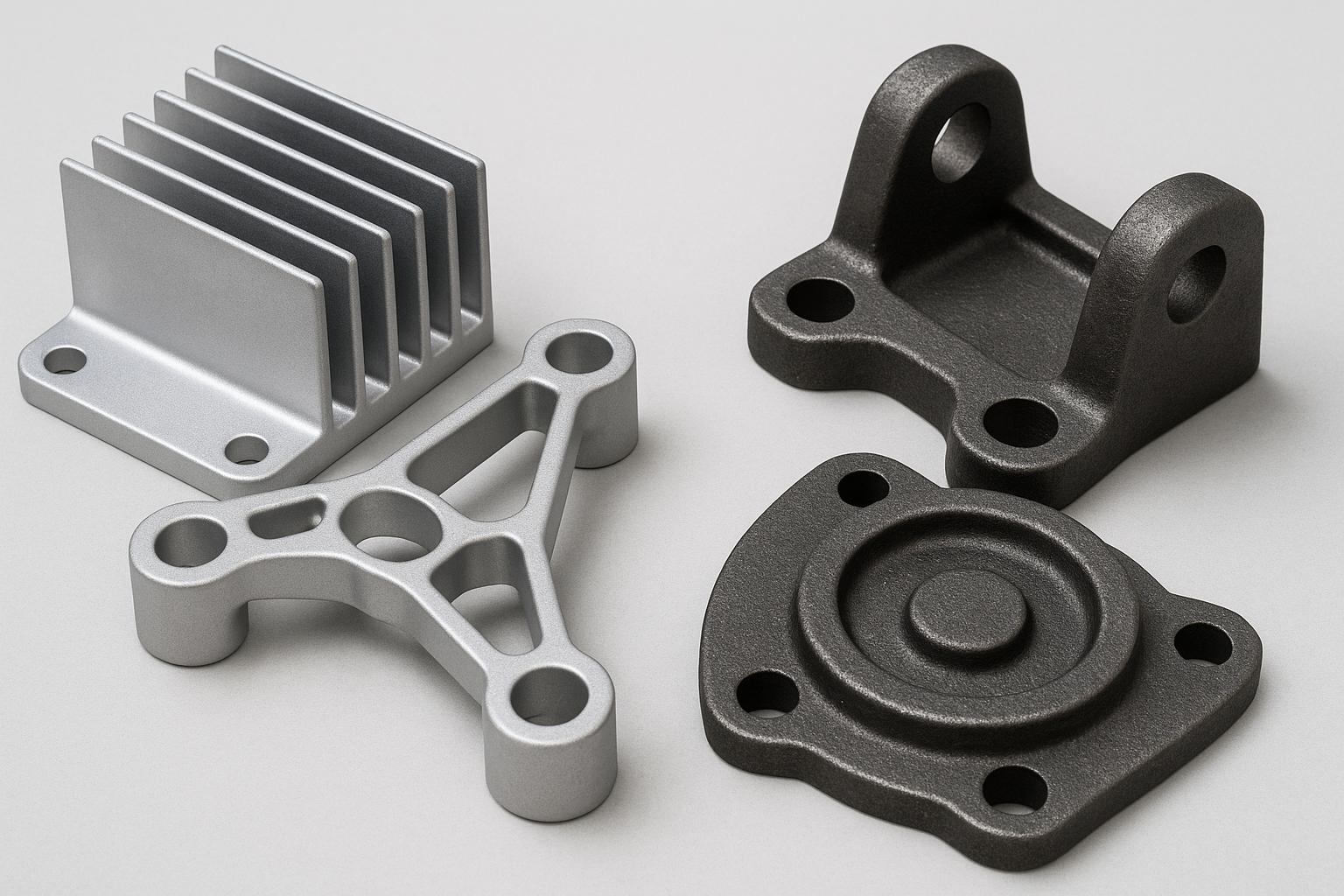

Stainless steel and carbon steel are two of the most widely used metal materials in today’s industry. While they both are based on iron and share some similar appearances, their distinct chemical compositions give them vastly different properties and applications. Understanding these fundamental differences is key to making the right choice for any engineering or manufacturing project.

What Are Carbon Steel and Stainless Steel?

Carbon steel is an alloy primarily composed of iron and carbon. Its carbon content typically ranges from 0.02% to 2.14%. Carbon steel is highly valued for its high strength, excellent hardness, and cost-effectiveness.

Stainless steel is an iron-based alloy that is distinguished by the presence of at least 10.5% chromium. This specific chromium content forms an invisible, passive protective layer on the steel’s surface, which gives stainless steel its exceptional resistance to corrosion.

Main Types of Carbon Steel

Based on their carbon content, carbon steels can be categorized into various types, with their properties changing accordingly:

- Low-Carbon Steel: Contains less than 0.25% carbon. It is highly ductile and has good weldability, commonly used for structural steel, sheet metal, and pipes.

- Medium-Carbon Steel: Contains 0.25% to 0.6% carbon. It has higher strength and hardness than low-carbon steel and is often used for manufacturing axles, gears, and rails.

- High-Carbon Steel: Contains 0.6% to 1.4% carbon. It is known for its high hardness and wear resistance, making it an ideal material for tools, springs, and molds.

Main Types of Stainless Steel

Stainless steel is primarily classified into the following types based on its crystal structure and composition:

- Austenitic Stainless Steel: The most common type, containing chromium and nickel. It is prized for its excellent corrosion resistance and ductility, exemplified by 304 and 316 stainless steel.

- Ferritic Stainless Steel: Contains chromium and is magnetic. It is a more cost-effective option often used in car exhaust systems and kitchenware.

- Martensitic Stainless Steel: Can be hardened by heat treatment. It has high strength and is commonly used for manufacturing knives and surgical instruments.

Core Performance Comparison

| Performance Metric | Stainless Steel | Carbon Steel |

| Corrosion Resistance | Excellent | Poor (Rusts easily) |

| Cost | High | Low |

| Hardness & Strength | Moderate to High | High |

| Weldability | Requires specific techniques | Good, easy to weld |

| Appearance | Bright, lustrous | Dull, prone to rust |

| Thermal Conductivity | Low | High |

Corrosion Resistance

This is the most significant difference between the two. Stainless steel resists rust because its surface chromium combines with oxygen to form a thin, durable chromium oxide passivation layer. This layer effectively prevents oxygen and moisture from corroding the steel underneath. Carbon steel, without chromium, reacts easily with oxygen in moist or exposed environments, leading to rapid rust formation.

Hardness and Strength

Carbon steel is generally harder and stronger than stainless steel, especially after heat treatment. Its hardness and strength increase significantly with higher carbon content. While some high-strength stainless steels (like martensitic grades) can achieve high hardness, carbon steel generally holds an advantage in terms of raw strength.

Machinability and Weldability

Carbon steel is typically easier to cut, drill, and weld than stainless steel. Due to its unique composition, stainless steel requires specific techniques and filler materials for welding to prevent the loss of its corrosion-resistant properties. This makes carbon steel a more common and practical choice for most general manufacturing and structural applications.

Cost

Cost is a crucial factor in material selection. Because stainless steel contains expensive alloying elements like chromium and nickel, its price is usually much higher than carbon steel. This makes carbon steel the preferred choice for projects with budget constraints and where high corrosion resistance is not a primary requirement.

Typical Application Scenarios

Due to their performance differences, these two types of steel are used in distinct fields.

Applications for Stainless Steel

Stainless steel is typically used in environments that demand high corrosion resistance and hygiene. Its applications include:

- Household Kitchenware: Sinks, cutlery, and kitchen appliances.

- Medical Equipment: Surgical instruments and medical implants.

- Chemical and Food Processing: Pipes, tanks, and processing equipment.

- Architecture and Decoration: Building facades, railings, and interior decor.

Applications for Carbon Steel

Carbon steel is primarily used in fields where high strength and cost-effectiveness are paramount, but high corrosion resistance is not required. Its applications include:

- Building Structures: Steel beams, rebar, and bridges.

- Transportation: Railroad tracks, car bodies, and frames.

- Tool Manufacturing: Hammers, screwdrivers, and blades.

- Heavy Machinery: Gears, bearings, and pipelines.

Conclusion

Choosing between stainless steel and carbon steel ultimately comes down to a trade-off between cost and performance. If your project requires excellent corrosion resistance and a pristine appearance, and your budget allows, stainless steel is the ideal choice. However, if your project prioritizes high strength and low cost, and can be used in a dry environment, carbon steel will be a more economical option.

Making the right material choice is critical for ensuring the success and longevity of your project.