In modern manufacturing, the demand for metal parts with high precision, excellent surface quality, and efficient production is constantly increasing. While traditional sand casting offers low cost, it often struggles to meet these stringent standards. Shell Molding, also known as the Croning Process, is a refined casting technique developed precisely to address these challenges. This article will explore the process, materials, advantages, disadvantages, and industrial applications of this advanced method.

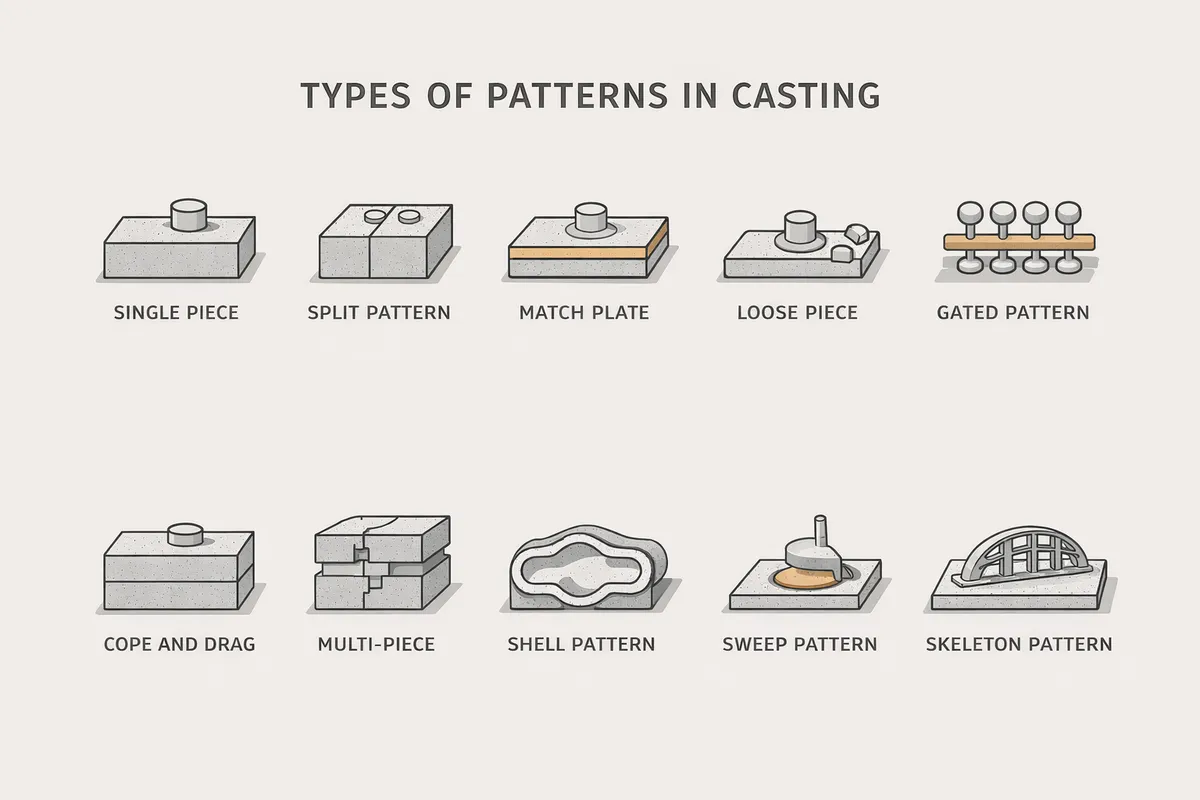

What is Shell Molding?

Shell molding, or the Croning Process, is an advanced, expendable mold casting method using a thin, rigid mold formed by a mixture of fine silica sand and a thermosetting phenolic resin binder. Unlike traditional sand casting, this technique utilizes a reusable heated metal pattern to partially cure the sand-resin mix, creating a strong, thin shell. This shell mold is prized for its ability to produce near-net-shape castings with high dimensional accuracy and a markedly superior surface finish, making it an essential process for high-volume manufacturing of complex components, particularly in ferrous metals like steel and cast iron.

How the Shell Molding Process Works

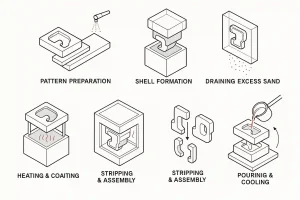

Shell molding is an expendable mold casting process where the mold is a thin-walled shell (typically 10 to 20 mm thick) made of resin-coated sand. The fundamental steps are as follows:

Shell molding process flow diagram (Croning process), showing seven key steps: Pattern Preparation, Heating & Coating, Shell Formation, Draining Excess Sand, Curing the Shell, Stripping & Assembly, and Pouring & Cooling.

- Pattern Preparation: A reusable metal pattern (usually cast iron or steel), corresponding to the shape of the desired part and accounting for shrinkage, is created in two halves.

- Heating and Lubricating the Pattern: The metal pattern is heated to a temperature between 175°C and 370°C (commonly 230°C to 260°C) and coated with a release agent (like calcium stearate) to prevent sticking.

- Shell Formation (Dumping): The heated pattern is clamped to a dump box containing resin-coated sand. The box is then inverted, and the heat partially cures a layer of the resin, forming a thin, firm shell.

- Draining Excess Sand: The box is reinverted; the loose, uncured sand falls away, leaving only the semi-cured shell adhered to the pattern.

- Curing the Shell: The shell is placed in an oven to fully cure the resin, achieving its final rigidity (tensile strength around 2.4 to 3.1 MPa).

- Stripping and Assembly: The cured shell half is ejected. Two or more halves are joined (clamped or glued) to form the complete mold. The mold is then often placed in a flask and supported by backing materials (sand or metal shot) for additional strength.

- Pouring and Cooling: Molten metal is poured into the mold cavity. After solidification, the shell is broken apart to extract the casting.

Materials Used in Shell Molding

- Shell Materials:

- Fine Silica Sand: Provides the refractory structure.

- Thermosetting Resin Binder: Most commonly Phenolic Resin (3% ~ 6% by weight), which acts as the high-strength binder when cured.

- Pattern Material:

- Typically Cast Iron or Steel for durability and heat cycling resistance. Graphite may be used for highly reactive metals.

- Castable Metals:

- The process is versatile, suitable for both ferrous and non-ferrous metals, including: Cast Irons (Gray, Ductile), Steels (Carbon, Alloy, Stainless), Aluminum Alloys, and Copper Alloys (Bronze, Brass).

Advantages of Shell Molding

- Superior Dimensional Accuracy: The rigid, resin-bonded shell provides much tighter tolerances (± 0.030 inches over 6 inches) than traditional sand casting.

- Excellent Surface Finish: Achieves a high-quality finish (around 200 to 250 RMS), minimizing post-processing.

- High Production Rate: Ideal for medium- to high-volume production due to automation capability and reusable metal patterns.

- Reduced Machining: High accuracy results in near-net-shape parts, significantly lowering overall manufacturing costs.

- Long Pattern Life: Durable metal patterns last for numerous cycles.

- Excellent Storage Life: Cured shell molds can be stored indefinitely.

Disadvantages and Limitations

- High Tooling Cost: The expensive metal patterns make the process uneconomical for low-volume runs.

- High Material Cost: Thermosetting resin is significantly more costly than the clay binders used in traditional sand casting.

- Size and Weight Limitations: Typically restricted to small- to medium-sized parts (generally under 30 kg or 65 lbs).

- Fumes and Odor: Resin decomposition during curing and pouring requires proper ventilation.

- Mold Strength: The thin shell may require external support for casting heavy parts.

Applications in Modern Industry

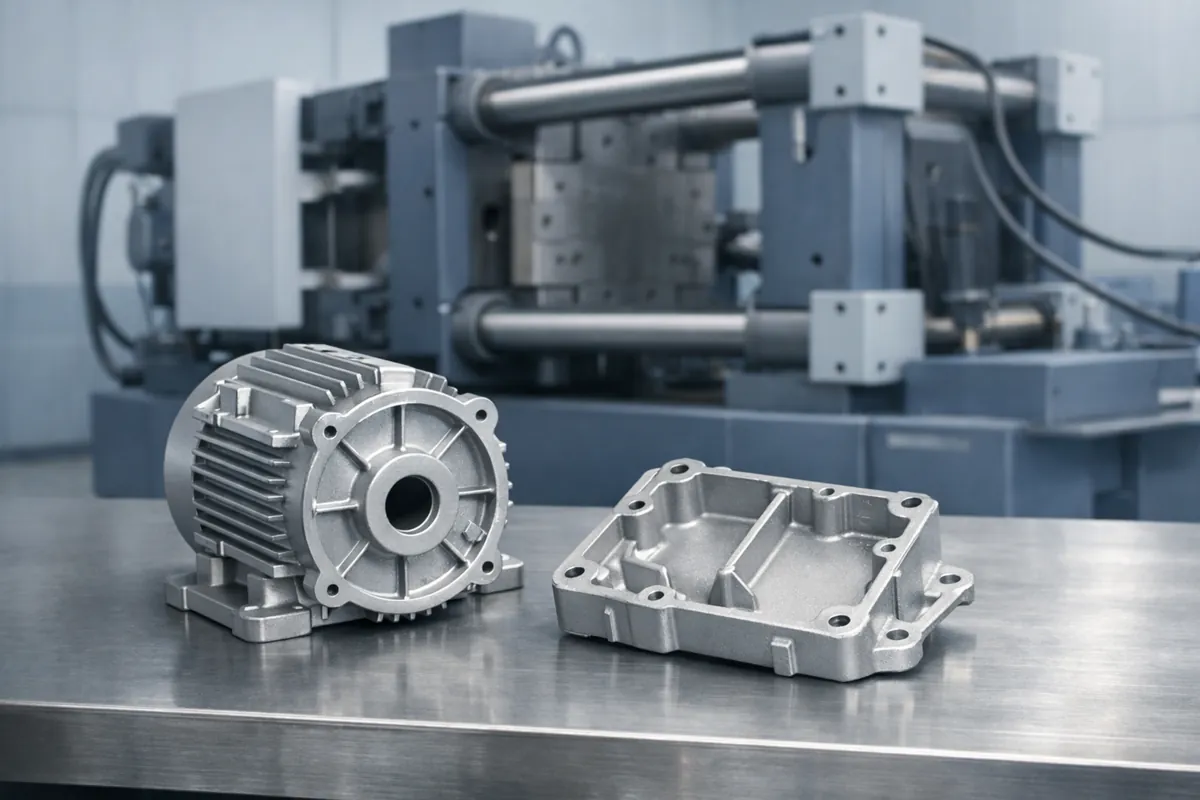

Shell molding is widely adopted in sectors requiring high-quality, repeatable components:

- Automotive Industry: Used for critical components like cylinder heads, crankshafts, camshafts, valve bodies, and transmission parts.

- Machinery Industry: Manufacturing pump housings, valve components, gears, and bearing caps.

- Aerospace & Energy Sector: Production of high-precision parts and fluid control components.

- Medical Equipment: Casting small, complex components.

Comparison with Other Casting Processes

Shell molding holds a strategic position, balancing cost and precision between common casting methods:

| Feature/Process | Shell Molding | Green Sand Casting | Investment Casting | Die Casting |

| Mold Type | Expendable thin shell (Resin-bonded sand) | Expendable bulk mold (Clay-bonded sand) | Expendable precision shell (Ceramic slurry) | Permanent metal mold (Die) |

| Pattern Type | Reusable metal pattern | Reusable wood/metal/plastic pattern | Expendable wax/plastic pattern | No pattern (Die is the mold) |

| Dimensional Accuracy | Medium-High (Better than sand) | Low (Least accurate) | Highest (Best precision) | High (Second best) |

| Surface Finish | Good (Smooth) | Poor (Rough) | Excellent (Smoothest) | Good/Excellent |

| Cost Structure | Medium-High (High pattern cost) | Low (Lowest) | High (Complex process) | Very High (Highest tooling cost) |

| Suitable Volume | Medium to High | Low to High | Small to Large | Very High |

| Suitable Materials | Ferrous and Non-ferrous | Nearly all metals | Nearly all metals | Low-melting point metals only (Al, Zn, Mg, Cu) |

Key Comparison Points:

- Versus Green Sand Casting: Shell molding trades higher tooling and material costs for superior accuracy, finish, and productivity.

- Versus Investment Casting: Shell molding is more cost-effective and faster for medium volumes, although it offers slightly lower ultimate precision.

- Versus Die Casting: Shell molding is essential for casting high-melting-point metals (like steel) that cannot be die cast.

Conclusion

Shell molding is a technologically mature and efficient solution for precision metal casting. If your project requires medium to high volumes of parts with stringent demands on dimensional accuracy and surface finish, shell molding is an essential choice for reducing post-casting machining costs and ensuring product quality.

Contact our casting specialists today to explore how shell molding can provide a precise and cost-effective solution for your critical components!