Powder coating is an advanced surface finishing technology that delivers exceptional protection, durability, and aesthetic consistency for metal parts. With zero VOC and solvent-free benefits, it has become a vital solution across machinery, automotive, architectural hardware, and home appliance industries.

This article covers what powder coating is, the working principle, common coating systems, suitable materials and pre-treatments, the step-by-step process and controls, advantages, durability and test standards, key limitations, casting-specific applications, and a concise FAQ.

What Is Powder Coating?

Powder coating is a solvent-free finishing process that electrostatically deposits a dry powder on conductive metal and cures it into a single, uniform film—delivering durable corrosion and wear protection with zero VOC emissions.

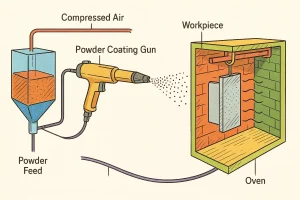

Working principle. Powder particles are electrically charged (typically negative) by a high-voltage spray gun and directed toward a grounded workpiece. Under Coulomb forces they deposit uniformly—even on complex geometries. During curing at 160–200 °C for 10–20 min, the powder melts, levels, and chemically cross-links into a dense thermoset layer.

Powder coating workflow with feed system, electrostatic gun, and curing stage.

Composition & traits. A typical formulation includes polymer resins (e.g., epoxy, polyester), pigments, curing agents, and functional additives. Key traits: solvent-free, zero VOC, inherently thicker/denser films, and high resistance to wear and impact.

Composition & Key Characteristics

A typical formulation includes polymer resins (e.g., epoxy, polyester), pigments, curing agents, and functional additives.

Key traits: solvent-free, zero VOC, inherently thicker/denser films, and high resistance to wear and mechanical impact.

Major Types of Powder Coating

The performance and suitability of powder coating depend on the polymer resin system used.

Four major powder coating types shown side by side: epoxy, polyester, hybrid, and polyurethane finishes.

Common types in engineering applications include:

Epoxy

Epoxy powder coatings offer excellent adhesion, superior chemical resistance, and high flexibility. They are commonly used for indoor applications, such as internal pipe coatings, machinery parts, and battery enclosures, where strong corrosion protection is required, but direct exposure to sunlight (UV) is avoided.

Polyester

Polyester coatings are known for their superior weather resistance and UV resistance, making them non-fading and highly durable for outdoor use. They are the ideal choice for exterior applications, including outdoor structures, automotive wheels, and architectural aluminum profiles.

Hybrid (Epoxy-Polyester)

Hybrid coatings combine the best properties of both epoxy and polyester resins, resulting in balanced performance across corrosion resistance and moderate weatherability. They are versatile and cost-effective, often used for general metal products, home appliance casings, and toolboxes.

Polyurethane / Acrylic

These types of coatings provide a high-quality finish characterized by high gloss, excellent flow, and a strong decorative appeal. They are frequently specified for applications requiring a premium aesthetic, such as automotive exterior trim and other high-value, high-aesthetic parts.

How the Process Works

Powder coating is a standardized four-step process, where pre-treatment is paramount to success.

- Surface Preparation:

This is the foundation for coat adhesion and corrosion performance. The process includes thorough degreasing, rust removal, rinsing, and the formation of a conversion coating like phosphating (for steel) or chrome-free conversion (for aluminum).

The surface roughness Ra is typically controlled between 1.6–3.2 µm to enhance mechanical anchoring. - Electrostatic Spraying:

The spray gun charges the powder particles, which are then electrostatically propelled and uniformly attracted to the grounded metal workpiece. - Curing & Cross-linking:

The powdered part enters a curing oven and is heated at 160–200 °C for 10–20 minutes.

The high temperature melts, levels, and initiates the irreversible cross-linking reaction to form the final durable protective film. - Cooling & Inspection:

After the part cools down, strict quality control is performed, including film-thickness measurement, gloss testing, and adhesion testing (e.g., cross-hatch test).

Materials and Base Metals

Powder coating is suitable for all electrically conductive metal substrates, and performance heavily relies on the correct match between the powder system and the base metal.

Common Substrates include: Aluminum and its alloys, Stainless Steel, Carbon Steel, Galvanized Steel, and Zinc Die-castings.

| Powder System | Typical Substrate | Characteristics |

| Epoxy | Steel parts | Strong adhesion, chemical resistant, primarily for interior use. |

| Polyester | Aluminum parts | UV resistant, excellent weatherability, preferred for outdoor use. |

| Hybrid | General metals | Cost-effective, balanced performance, high versatility. |

Recommended Pre-treatment: For carbon steel, sandblasting + phosphating is suggested; for aluminum, a chrome-free conversion coating is recommended. These conversion treatments significantly enhance the coating’s bond strength and corrosion resistance.

Advantages of Powder Coating

Powder coating is the preferred choice for many engineers and procurement managers due due to its multiple core advantages:

- High Protection: The thick, dense coating provides excellent corrosion resistance, abrasion resistance, and UV resistance.

- Environmental Benefit: Solvent-free and zero VOC emissions; unused powder is reclaimed, meeting the strictest environmental standards.

- Aesthetic Versatility: Can achieve various customized finishes like matte, glossy, textured, hammer-tone, and metallic flakes.

- Efficient Process: Compared to multi-layer wet paint, powder coating is single-coat, offers shorter production cycles, and is ideal for mass production.

- Durable Film: The cured film exhibits excellent impact resistance, is resistant to cracking or chipping, and requires minimal maintenance.

Durability & Service Life

Powder coating is renowned for its outstanding mechanical strength and environmental stability, representing long-term protection.

Under normal industrial and outdoor conditions, a quality powder coat can provide stable protection for 5–15 years. The actual service life depends on the powder system, film thickness, and environmental exposure. In indoor settings, high-quality epoxy coatings can last over a decade.

Key Durability Factors: The coating’s durability is directly affected by its thickness and density, curing quality, and environmental conditions. Only fully cross-linked films achieve maximum impact strength and adhesion. In high-humidity or strong UV environments, Polyester or Fluorocarbon systems must be selected. Durability is typically verified using industry standards such as the ASTM B117 salt spray test (quality coatings often require ≥ 1000 h) and the ASTM D2794 impact test.

Limitations of Powder Coating

In engineering applications, it is crucial to recognize the technical limitations of powder coating:

- Not applicable to non-conductive substrates (requires specialized primer or metallization for materials like plastic or wood).

- Thin Film Control Difficulty: Minimum film thickness is typically around 50 µm, making it unsuitable for parts requiring precise clearances or fine threads due to tolerance impact.

- Complex Color Change: Cleaning the spray booth and reclamation system is time-consuming, leading to high color changeover costs, making it inefficient for small-batch, multi-color orders.

- Curing is influenced by the part’s thermal mass; large or complex parts risk uneven curing.

- Difficult Local Repair: Damage to the coating is hard to repair locally and usually necessitates complete recoating.

👉 Design Suggestion: During the design phase, thoroughly consider the part’s conductivity, geometry, color quantities, and batch characteristics to ensure the powder coating process is economical and consistent.

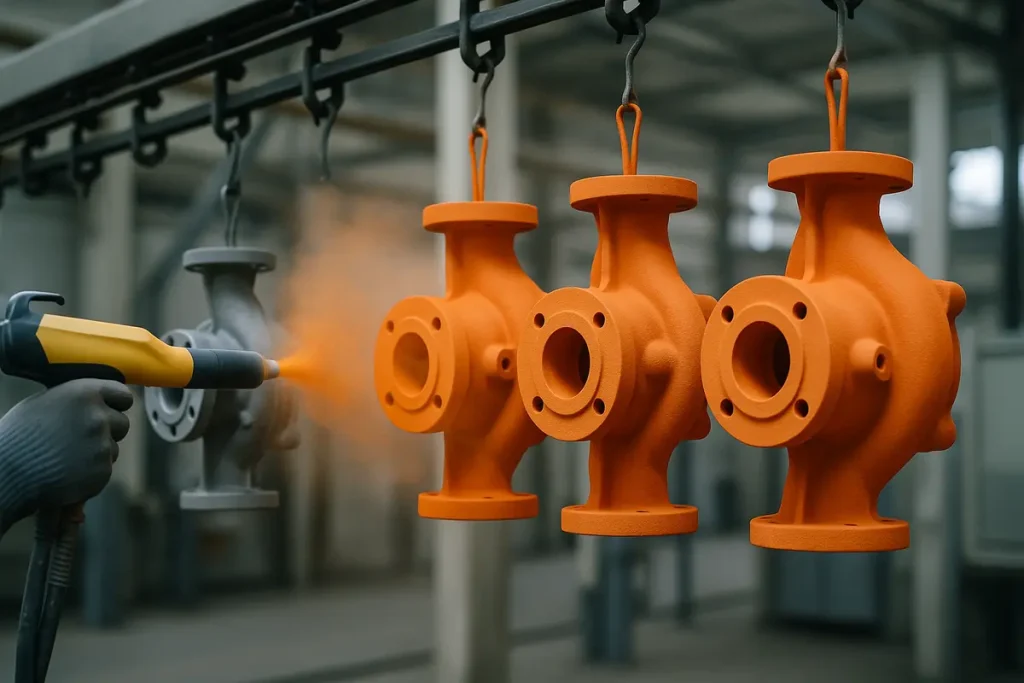

Applications of Powder Coating

Powder coating is widely used for the protection and decoration of various metals and casting surfaces. It not only enhances aesthetic consistency but also provides effective corrosion protection in humid, salt spray, and abrasive environments.

Common applications include:

- Cast Iron and Steel Castings: Valves, pump housings, motor bases, and pipe fittings requiring high corrosion resistance.

- Aluminum Castings: Various precise housings, decorative components, automotive wheels, and engine parts.

- Architectural and Outdoor Castings: Railings, lighting fixtures, decorative elements, and outdoor furniture.

- Industrial Equipment: Control cabinets, equipment enclosures, brackets, and structural components.

In casting post-processing, powder coating is often the final surface protection step, used in conjunction with processes like sandblasting, phosphating, or primer coating to form a multi-layer protective system that significantly extends the cast part’s lifespan.

Conclusion

Powder coating, with its high adhesion, superior corrosion resistance, and environmental benefits, is an indispensable part of casting post-processing. By precisely controlling curing temperature and pre-treatment quality, it can significantly extend the lifespan of cast parts and enhance their final appearance and quality, offering a high-value, long-lasting surface solution for modern manufacturing.

Request a quote or talk with our foundry engineers today.

FAQs

1️⃣ What is the typical thickness of a powder coating?

Usually between 50–150 µm. For precision-fit parts, it can be controlled to 40–60 µm.

2️⃣ What is the curing temperature for powder coating?

Generally 160–200 °C for 10–20 minutes. Epoxy typically cures at the lower end of this range, while Polyester tends to require slightly higher temperatures.

3️⃣ What are common defects in powder coating?

Orange peel, pinholes, bubbles, craters, and color variation, mainly caused by insufficient pre-treatment or uneven curing.

4️⃣ Can aluminum or stainless steel be powder-coated?

Yes. Both require thorough cleaning and typically sandblasting or phosphating/conversion coating to improve adhesion.

5️⃣ Is powder coating good for outdoor use?

Yes. Polyester and Fluorocarbon systems offer excellent weather and UV resistance, making them the preferred choice for outdoor applications.