Plaster Mold Casting is a precision metalworking technique valued for its ability to reproduce fine detail and superior surface finish in non-ferrous components. This process utilizes gypsum-based materials to create molds, distinguishing it from coarser sand-based methods.

As a versatile precision casting technology, plaster mold casting serves as a strategic choice for engineers and manufacturers who require thin walls and tight tolerances in materials like aluminum and copper alloys. This evaluation-driven guide details the mechanism, materials, comparisons, and industrial applications of the CC method.

What Is Plaster Mold Casting

Plaster mold casting is an industrial metal casting process using gypsum-based molds, rather than ceramic or sand, to form complex, non-ferrous parts. The key characteristic of this method is the mold material’s ability to capture the fine details of the pattern, resulting in excellent surface finish and dimensional accuracy that rivals investment casting but at a lower cost for certain batch sizes. The purpose of plaster mold casting is to reproduce intricate geometries and fine surface detail in non-ferrous parts, typically those requiring high aesthetic quality or precise hydraulic sealing, without the need for extensive post-casting machining.

How the Process Works

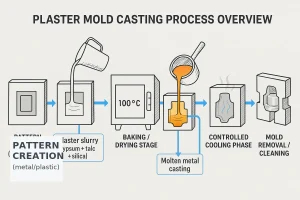

The complete plaster casting process is fundamentally a lost-wax variant, adapted to utilize gypsum compounds. The mechanism is characterized by a high degree of precision in mold formation followed by specialized drying procedures to ensure mold integrity during the pour.

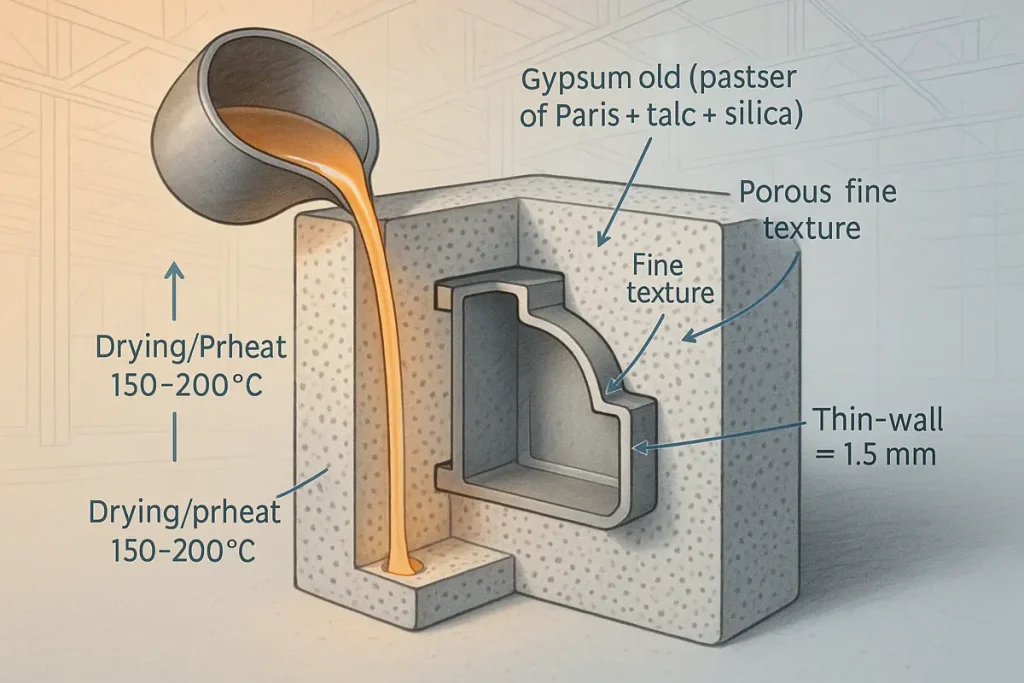

Illustration of the plaster mold casting process — from pattern creation and plaster slurry pouring to drying, metal casting, and mold removal.

Pattern Preparation

The process begins with creating a master pattern, usually made from aluminum, brass, or plastic, that precisely matches the desired final component dimensions, with allowances for metal shrinkage. For parts requiring cores, a separate core box is manufactured. The pattern must exhibit a very smooth surface finish, as the plaster mold casting will perfectly replicate all surface imperfections.

Slurry and Mold Assembly

Next, a gypsum-based slurry—a mixture of plaster of Paris, water, and anti-cracking agents—is prepared. This slurry is poured over the pattern or into a flask containing the pattern. Due to the high flowability of the gypsum mold slurry, it readily fills even the smallest features and details of the pattern. Once the slurry sets (typically within 15–20 minutes), the mold halves are separated, and the pattern is carefully removed.

Baking and Drying

The mold then undergoes an intensive, multi-stage baking and drying process. This step is critical because the plaster mold contains residual moisture that must be completely removed to prevent steam generation during pouring, which could lead to severe surface defects or explosions. The initial phase removes free water, and the subsequent high-temperature baking converts residual chemically bound water into steam, resulting in a strong, porous structure with sufficient permeability to vent trapped air during casting. This specialized drying process is one of the rate-limiting factors of the entire CC method.

Casting and Solidification

With the mold fully baked and often still hot (around 150–200°C), the molten metal—typically low-melting-point non-ferrous metals such as aluminum or copper alloys—is poured into the mold cavity. The high thermal resistance of the plaster allows the metal to solidify relatively slowly, promoting uniform grain structure. Once solidified, the plaster is broken away from the final plaster casting. The gypsum mold is consumable and cannot be reused.

Materials Used in Plaster Casting

The mold utilized in this precision method is composed of specific materials designed to impart fine detail and stability at elevated temperatures. The core ingredient of the gypsum mold composition is plaster of Paris (calcium sulfate hemihydrate, CaSO₄·½H₂O), known for its excellent detail-reproduction capability and rapid setting time.

To enhance the mold’s structural integrity, thermal stability, and essential permeability, additives are introduced. These typically include talc, silica, fiberglass fibers, and anti-shrinkage agents. The silica provides resistance to cracking during the critical high-temperature baking stage, while the talc and other fine powders help control the mold’s porosity, ensuring gases can escape during the pour without creating surface defects.

Plaster mold casting is almost exclusively reserved for non-ferrous metals with relatively low melting points. The most common materials cast are:

- Aluminum Alloys (e.g., Al–Si): Excellent fluidity and strength-to-weight ratio; ideal for complex components requiring fine detail.

- Copper Alloys (e.g., Brass, Bronze): Used for plumbing fixtures, decorative parts, and components needing good corrosion resistance.

- Magnesium and Zinc Alloys: Less common, but used when specific weight or mechanical properties are necessary.

The maximum service temperature of the gypsum mold limits the material selection; steel and iron alloys are generally unsuitable as their high liquidus temperatures would damage the mold structure.

Advantages of Plaster Mold Casting

From an engineering perspective, plaster mold casting provides a high-fidelity manufacturing route, particularly where surface quality and intricate features are paramount.

The primary benefits of plaster mold casting include:

- Superior Surface Finish: The fine particle size of the gypsum slurry results in a finish as fine as Ra 0.8–3.2 µm, significantly smoother than traditional sand casting and comparable to investment casting.

- Excellent Dimensional Accuracy: Tolerances are typically maintained at ±0.25 mm for small dimensions, making the plaster casting method ideal for components requiring precise mating surfaces.

- Intricate Geometry Capability: The high flowability of the plaster slurry allows for the reproduction of thin walls (down to 1.5 mm) and complex internal features, which is critical for hydraulic components.

- Reduced Machining Costs: Due to the high accuracy and finish achieved, post-casting machining is often minimized or eliminated, leading to significant cost savings.

- Lower Tooling Costs (vs. Permanent Mold): Although the molds are consumable, the tooling cost for creating the patterns is lower than for permanent (metal) molds, making it economical for medium volume batches.

Limitations of Plaster Mold Casting

Despite its advantages in precision, plaster mold casting presents several key constraints that must be accounted for in process selection.

The most significant disadvantages of plaster mold casting are:

- Material Restriction: The process is strictly limited to non-ferrous metals (aluminum, brass, bronze, etc.) because the gypsum mold rapidly degrades above 1200°C, making it unsuitable for steel or cast iron.

- Slow Production Cycle: The mandatory, extended baking and drying period required to remove moisture from the mold material is time-consuming (often over 12 hours), significantly slowing down the overall production rate compared to automated sand or permanent mold methods.

- Mold Consumability: Like sand and investment casting, the plaster mold is destroyed to retrieve the part, increasing material waste and labor required for mold preparation.

- Size and Weight Limits: The process is best suited for small to medium-sized components, generally limiting parts to a maximum weight of about 20 kg. Larger, heavier parts become impractical due to the fragility and handling complexity of the large plaster molds.

- Poor Permeability (Initial State): Although baking improves porosity, the plaster mold’s inherent fine grain size results in lower gas permeability than sand molds, requiring careful gating and venting design.

Plaster Mold Casting vs Other Casting Methods

When selecting a manufacturing route, project managers must understand how plaster mold casting compares to other established methods in terms of cost, precision, and application volume. This comparative analysis highlights its strategic niche.

Vs Sand Casting

| Feature | Plaster Mold Casting | Sand Casting (Green/No-Bake) | Strategic Difference |

|---|---|---|---|

| Mold Material | Gypsum, talc, silica | Silica sand, clay | Material determines detail fidelity. |

| Surface Finish | Excellent (Ra 0.8–3.2 µm) | Fair to Good (Ra 6.3–25 µm) | Plaster eliminates most post-processing. |

| Dimensional Tolerance | High (±0.25 mm) | Low (±0.8 mm to ±2 mm) | Plaster is far more precise. |

| Cost (Tooling) | Moderate (Pattern is non-metal) | Low (Pattern can be wood/plastic) | Similar, but plaster needs specialized flasks. |

| Metal Suitability | Non-ferrous only (Max 1200°C) | Ferrous and Non-ferrous (Max 1600°C) | Sand offers broader material range. |

| Production Speed | Slow (Long baking cycle) | Fast (Automation available) | Sand is preferred for high volume and speed. |

Vs Investment Casting

Investment casting (lost-wax) is the primary competitor in the high-precision, fine-detail market.

| Feature | Plaster Mold Casting | Investment Casting (Lost-Wax) | Strategic Difference |

|---|---|---|---|

| Mold Material | Gypsum-based | Ceramic shell (Zircon, Alumina) | Ceramic shells handle higher temperatures. |

| Surface Finish | Excellent | Superior (Ra 0.4–1.6 µm) | Investment casting is slightly better. |

| Dimensional Tolerance | High (±0.25 mm) | Very High (±0.1 mm) | Investment casting offers the tightest tolerances. |

| Tooling | Requires pattern | Requires wax pattern dies (high cost) | Plaster tooling is cheaper for short–to–medium runs. |

| Metal Suitability | Non-ferrous only | Almost all metals (steel, superalloys) | Investment casting is indispensable for high-temp alloys. |

| Economic Range | Medium Volume (100–10000 units) | Low to Very High Volume | Plaster fits the medium-run niche for non-ferrous parts. |

Vs Permanent Mold Casting

Permanent mold casting uses durable metal molds, fundamentally changing the cost and speed equation.

| Feature | Plaster Mold Casting | Permanent Mold Casting (Gravity Die) | Strategic Difference |

|---|---|---|---|

| Mold Material | Consumable Plaster | Reusable Metal (Cast Iron/Steel) | Molds are the main cost driver. |

| Tooling Cost | Low to Medium | Very High | Permanent mold cost is amortized over massive volumes. |

| Production Speed | Slow (due to baking) | Very Fast (high automation) | Permanent mold is the fastest method. |

| Grain Structure | Finer (Slower cooling) | Coarser (Rapid cooling) | Permanent mold leads to rapid solidification and better mechanical properties. |

| Geometry Complexity | High (intricate features) | Moderate (limited by mold opening) | Plaster can handle more complex undercuts and thin walls. |

| Economic Range | Medium Volume | High to Very High Volume | Plaster is viable below 10000 units/year. |

Applications in Modern Industry

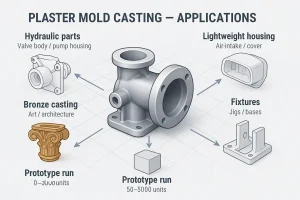

The capacity of plaster mold casting to produce high-integrity, detailed components makes it indispensable across several specialized sectors. This process is primarily used for aluminum and copper alloy components that demand excellent surface quality and precise dimensional control.

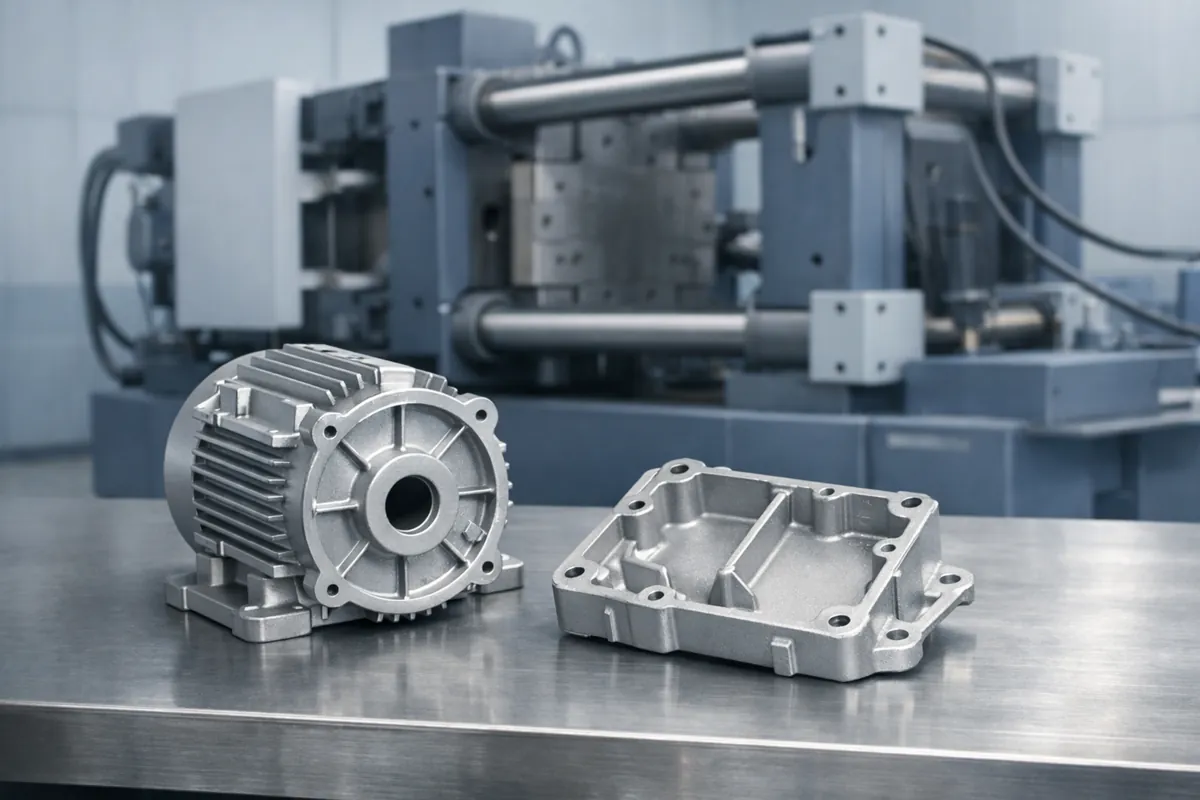

Semi-realistic industrial illustration showing typical non-ferrous applications of plaster mold casting.

Key industrial sectors leveraging this casting method include:

- Aerospace: Used for complex air intake components, housings, and small structural parts where minimal weight and a smooth finish are necessary to maintain aerodynamic efficiency.

- Prototyping and Short Runs: Due to the relatively low cost of pattern tooling compared to metal dies, it is an economical choice for producing prototypes or limited series production (typically 50 to 5000 units).

- Automotive: Manufacturing torque converter components, hydraulic valve bodies, and pump housings that require intricate internal passageways and non-porous surfaces for fluid sealing.

- Art and Decorative Castings: Brass, bronze, and aluminum statues or decorative architectural elements often utilize plaster mold casting to ensure fine artistic detail is captured without extensive grinding or polishing.

- Electrical/Electronics: Production of heat sinks and electrical housings where the complex geometry must be achieved with high precision.

Conclusion

Plaster mold casting successfully occupies a strategic niche between high-volume, low-precision sand casting and the ultimate precision, high-cost investment casting. It offers engineers a route to achieve thin walls, intricate detail, and superior surface finish in non-ferrous metals without the initial capital outlay associated with permanent metal tooling. This makes it particularly valuable for prototypes, specialized low–to–medium volume production, and applications requiring aesthetic excellence. Understanding its limitations—chiefly material restrictions and slow cycle time—is essential for optimal manufacturing selection.