In the modern precision manufacturing landscape, selecting the appropriate forming process is a pivotal decision that optimizes both product performance and cost structure. While Investment Casting and Die Casting are both premier metal casting techniques, they diverge significantly in material properties, production scales, and design flexibility. A deep understanding of the technical logic behind these two processes is a prerequisite for ensuring project success.

What is Die Casting

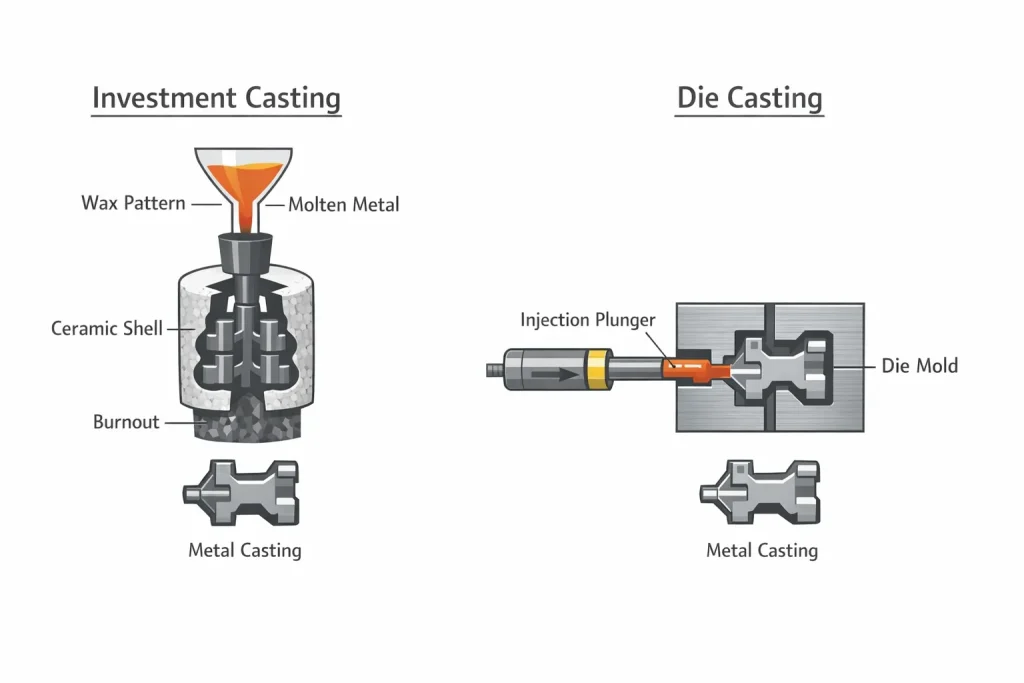

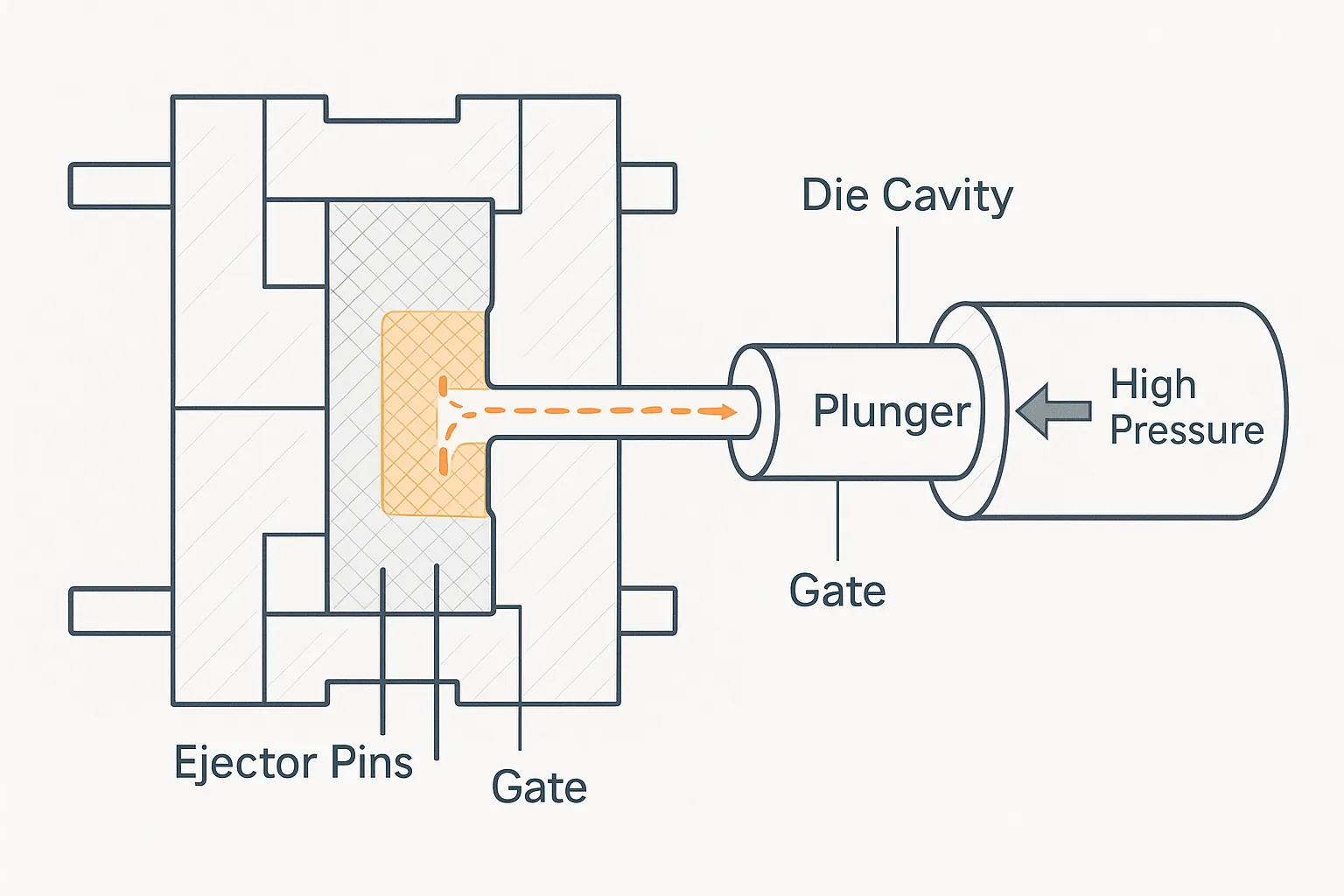

Die casting utilizes the high-pressure mechanism of a die casting machine to force molten metal into precision steel molds at millisecond speeds. Under this mechanical pressure, the liquid metal rapidly overcomes flow resistance to fill intricate cavities, forming a dense and robust structure.

The process relies on permanent molds crafted from high-performance hot-work tool steel. These molds possess exceptional thermal fatigue resistance, allowing them to withstand tens of thousands of thermal shocks and high-pressure impacts. This ensures consistent part dimensions and high precision throughout large-scale

Depending on the metal injection method, the process is categorized into two types: cold chamber and hot chamber. Cold chamber die casting is used for high-melting-point alloys like aluminum and copper, while hot chamber die casting offers superior automation efficiency for lower-melting-point alloys such as zinc and magnesium.

Advantages of Die Casting

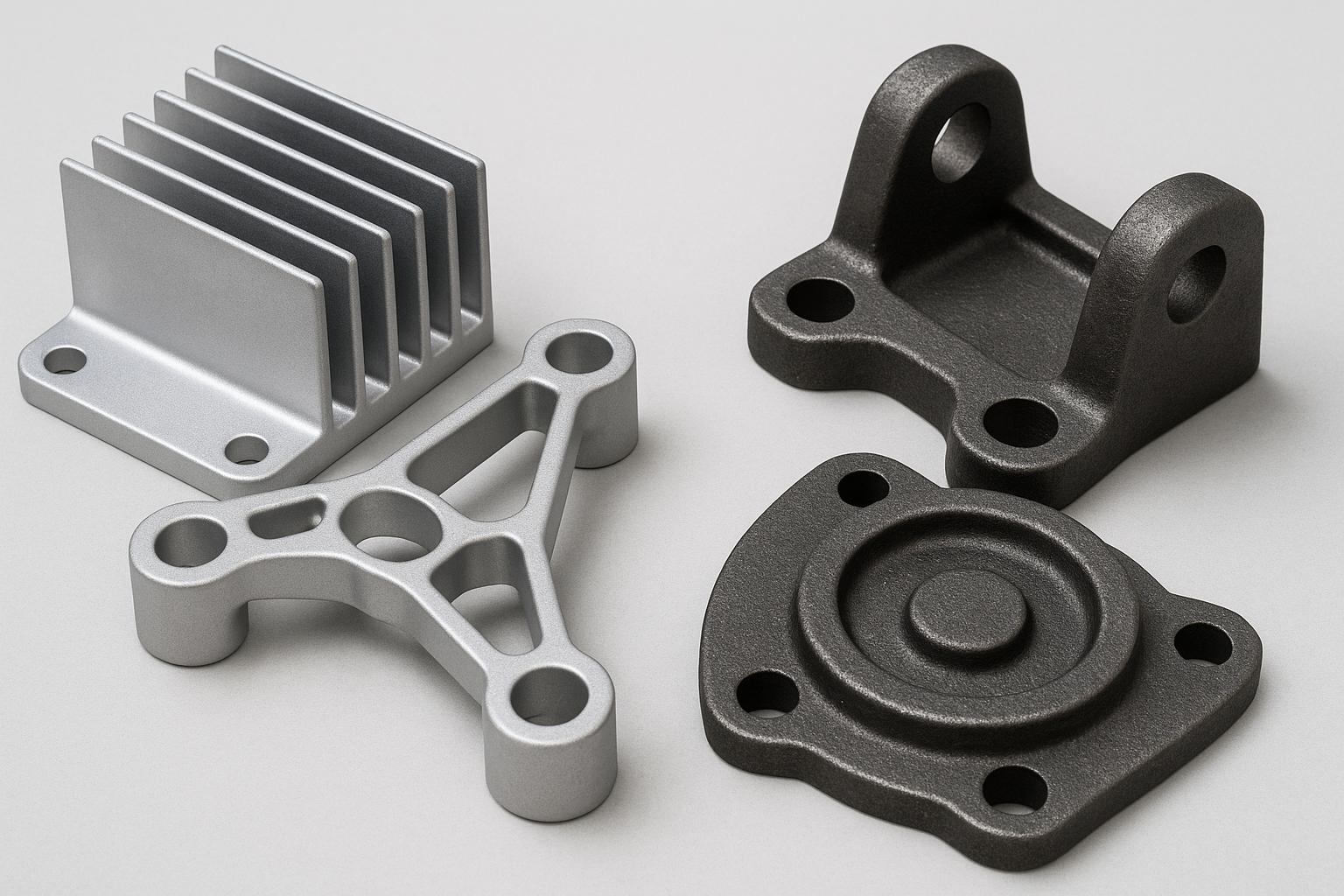

With its exceptional industrial efficiency and dimensional stability, die casting is the premier choice for mass production in industries such as automotive, consumer electronics, and hardware tools.

- Exceptional Production Efficiency: Cycle times are typically measured in seconds, and the high degree of automation makes it one of the fastest metal forming processes available.

- Superior Dimensional Accuracy: It can produce extremely thin-walled parts with tight tolerances, significantly reducing or eliminating the need for secondary machining.

- High Surface Quality: The surface finish is excellent, usually requiring only minimal treatment to meet aesthetic requirements after de-molding.

- Stable Mechanical Properties: Rapid solidification under high pressure results in a dense microstructure and fine grain size, ensuring consistent strength.

What is Investment Casting

Investment casting, also known as “lost wax casting,” centers on the sacrificial logic of “replacing wax with metal.” The process begins by creating a wax pattern identical to the part’s geometry, which is then assembled into a “casting tree” to serve as the precision master for the ceramic shell.

By repeatedly dipping the wax assembly into ceramic slurry and coating it with refractory sand, a hard, heat-resistant ceramic shell is built. Subsequently, the wax is melted out at high temperatures (dewaxing), leaving behind a seamless, hollow mold.

Once the shell is fired and strengthened, molten metal is poured in. Since the ceramic shell is ultimately broken away to retrieve the part, this process bypasses the limitations of traditional metal molds, enabling the creation of extremely complex internal channels or undercut geometries.

Advantages of Investment Casting

The core value of investment casting lies in its nearly limitless design freedom and excellent compatibility with high-performance materials, making it dominant in aerospace, medical implants, and precision machinery.

- Extreme Design Freedom: Intricate internal cavities and fine textures are easily achieved, and because no physical de-molding is required, there is no need for draft angles.

- Broad Material Versatility: It can cast almost any metal, including stainless steel, carbon steel, superalloys, and titanium alloys.

- Fine Surface Detail: The ceramic shell imparts high-fidelity detail, clearly reproducing small text, logos, or anti-counterfeiting features.

- Structural Integration: It allows for the consolidation of multiple components into a single integral casting, eliminating welding or fasteners, improving reliability, and reducing weight.

Differences Between Die Casting and Investment Casting

While both processes aim to deliver high-quality metal components, they operate on fundamentally different physical mechanisms and thermodynamic principles, directly affecting internal quality and economic outcomes.

Filling Pressure and Flow Characteristics

Die casting is a high-pressure, high-velocity process where molten metal fills the cavity instantaneously. This high-energy injection is ideal for ultra-thin walls, but the resulting turbulence can trap minor amounts of gas. Conversely, investment casting typically relies on gravity or vacuum environments for steady pouring. The metal flows in a laminar state into a breathable ceramic shell, ensuring superior metallurgical purity—making it the first choice for safety-critical components and pressure vessels.

Tooling Life and Long-term Cost Structure

Die casting relies on permanent metal molds that require significant upfront investment (often tens of thousands of dollars) and long lead times. However, for mass production exceeding 10,000 units, the per-unit amortization cost is extremely low. Investment casting uses sacrificial ceramic shells. While the initial master tooling (for wax patterns) is cheaper and faster to iterate, the labor-intensive nature of shell building and removal means the unit price does not see the same “cliff-like” drop as die casting when volumes increase.

Material Range and Physical Limits

Die casting is strictly limited by the thermal endurance of steel molds, primarily confined to non-ferrous light alloys like aluminum, zinc, and magnesium. Investment casting utilizes highly refractory ceramic shells capable of withstanding temperatures over $1500^{\circ}C$. This grants it an irreplaceable position in handling ferrous metals (such as stainless and heat-resistant steels) and nickel-based superalloys, serving as the industry standard for turbine blades and chemical valves.

Manufacturing Flexibility and Design Iteration

In terms of manufacturing flexibility, investment casting holds a clear lead. It supports complex biomimetic structures and integrated designs that are impossible to de-mold in a rigid die. Furthermore, because wax patterns can be generated via 3D printing, it is ideal for low-volume customization or rapid prototyping. Die casting, meanwhile, focuses on high consistency and output speed; once the die is cast, design changes are prohibitively expensive, making it best suited for standardized mass production.

Conclusion

In summary, die casting is the manufacturing powerhouse for “scale, speed, and low unit price,” whereas investment casting is the ultimate path for addressing “complexity, high strength, and exotic materials.” Choosing between them is essentially an exercise in finding the optimal balance between design limits and economic scale.

If you are evaluating the best casting solution for a specific part, please contact our technical team. We will provide you with a professional DFM (Design for Manufacturing) assessment and customized process recommendations.