Investment casting is a precision manufacturing process that combines traditional techniques with modern accuracy demands, reliably producing complex parts with high precision. Often referred to as lost-wax casting, this method is an important process choice for industries requiring intricate geometries and superior surface finishes. This guide is intended to serve as a reference for engineering personnel, analyzing the process, material options, and clarifying its application standards in design and procurement.

What Is Investment Casting (Lost-Wax Process)?

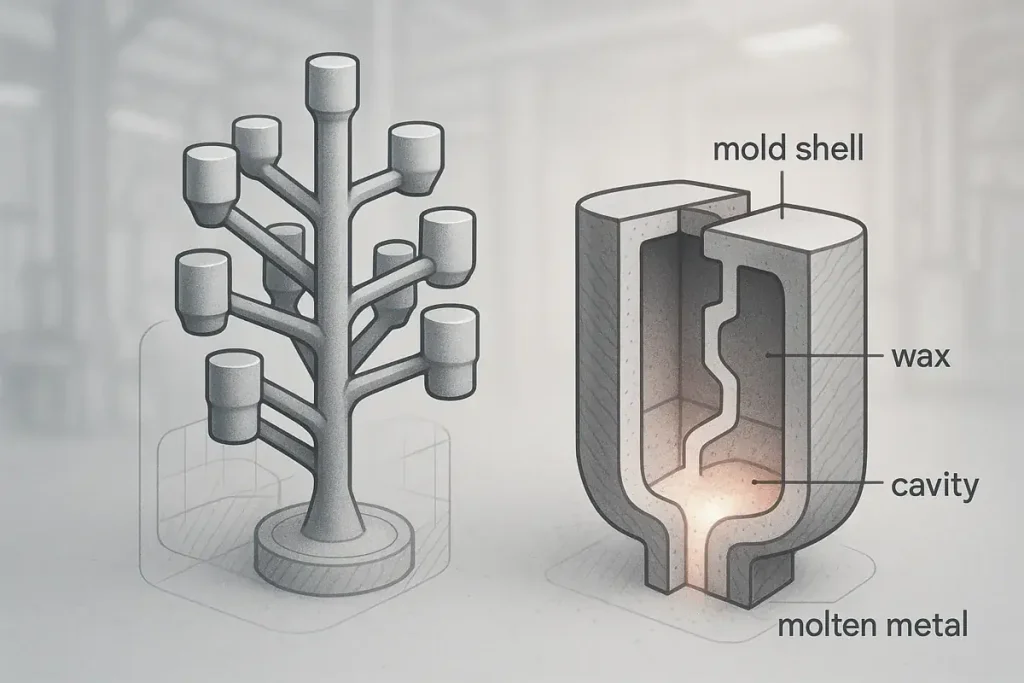

Investment Casting (also known as lost-wax casting or precision casting) is a metal forming technique noted for its unique methodology and consistent output quality. The core of this technology involves building a ceramic shell around a wax pattern — an exact replica of the final part.

The term lost-wax casting refers to the critical step where the wax pattern is melted and drained out of the ceramic shell before the molten metal is poured. The term “investment” describes the process of precisely coating the pattern in refractory slurry. This technology is one of the oldest known metal forming methods, and its application in modern industry proves its reliability and lasting value.

Investment Casting Process: Step-by-Step Overview

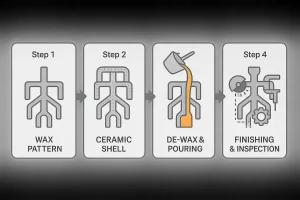

The accuracy of investment casting is built on its strictly controlled multi-stage process. How does Investment Casting work? Understanding these key steps helps in comprehending the process’ complexity and scheduling.

Step-by-step illustration of the investment casting process, from wax pattern creation to ceramic shell building, molten metal pouring, and final inspection.

Wax Pattern Creation

The process starts by injecting wax into a master die (tooling) to create an exact wax replica of the final part. (Note: The quality of the tooling directly influences the final part accuracy.)

Assembly and Tree Building

Individual wax patterns are attached to a central wax sprue to form a “tree” assembly. This structure is generally used to optimize the metal filling efficiency during pouring.

Shell Building (Investing)

The tree is repeatedly dipped into a refractory ceramic slurry and coated with fine sand. This sequence typically requires 6 to 8 cycles to ensure the shell has sufficient strength and thickness to withstand the metal’s high heat and pressure.

De-waxing (Lost-Wax)

What happens during the de-waxing process? The shell is heated in an autoclave or furnace, typically ranging from 90∘C to 175∘C, causing the wax to melt and drain out, leaving a hollow mold cavity.

Pouring and Casting

Molten metal is poured into the ceramic mold, which is often preheated to a temperature between 800∘C and 1100∘C. Preheating is an important step to ensure good metal flow and complete filling of complex sections.

Finishing and Part Removal

What are the final steps of the process? The ceramic shell is mechanically or hydraulically broken away, and the cast parts are cut from the sprue. Finishing work is used to remove gate residue and achieve required surface treatments.

Best Materials for Investment Casting

The high compatibility of investment casting is an advantage compared to die casting. What materials can be used, and can stainless steel be investment cast? The process supports a wide selection of alloys.

- Stainless Steels (300 and 400 Series): A commonly used choice in engineering applications due to its good corrosion resistance and strength.

- Carbon and Low Alloy Steels: Often used for critical load-bearing parts that require specific strength and hardenability.

- Non-Ferrous Metals: Aluminum and Copper alloys (Brass and Bronze) can be cast successfully.

- Superalloys: Including Nickel and Cobalt base alloys, these materials are typically utilized in aerospace and energy components requiring extreme high temperatures (e.g., turbine blades).

Advantages and Limitations of Investment Casting

When selecting a process, engineers usually compare the core pros and cons of this method. What are the pros and cons of investment casting?

Key Advantages

- High Dimensional Accuracy: It can reliably achieve tolerances of Grade CT5–CT7, which usually helps reduce or eliminate the need for secondary machining.

- Complex Geometries: The process supports internal passageways, fine details, and thin wall sections down to 0.75 mm.

- Superior As-Cast Surface Finish: The ceramic mold can provide an as-cast surface quality ranging from Ra 3.2μm to Ra 6.3μm.

- Broad Material Compatibility: It can process many refractory and hard-to-machine alloys.

Limitations

- Higher Cost per Part at Low Volume: The unit cost at low volume may be higher than sand casting due to the complex process and initial tooling investment.

- Longer Lead Time: The shell building and drying cycles may extend the project production schedule.

Applicability Assessment: Investment casting is a recommended choice when parts have complex geometric requirements, require high precision, or when the project goal is to reduce post-casting machining workload. For simple, high-volume parts, die casting or forging is typically considered.

Applications and Example Parts

The reliability and precision offered by investment casting drive its use in high-reliability sectors. What are the common applications of investment casting, and what parts does it make?

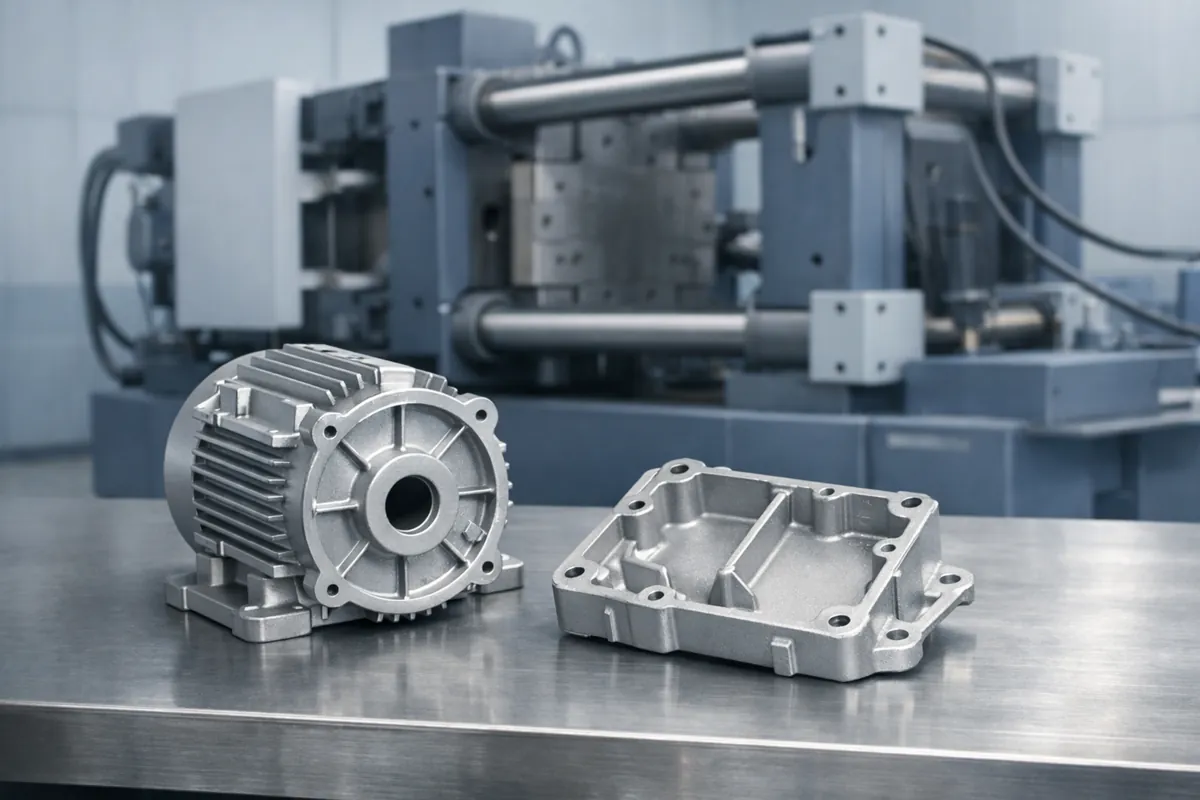

- Aerospace and Energy: Typical parts are turbine blades and key jet engine components, which are frequently made using investment casting due to their complex internal cooling channels and superalloy material requirements.

- Medical Devices: Includes surgical tools and implants that require high surface finish and biocompatibility.

- Automotive and Industrial: Used to produce turbocharger housings, pump impellers requiring precise hydrodynamics, and complex valve bodies.

Investment Casting vs. Sand Casting and Die Casting

When selecting a process, it is standard practice to compare the key differences between investment casting and other common methods. How does Investment Casting compare to Sand Casting and Die Casting in terms of accuracy and cost? Each method targets specific production objectives.

Investment casting is superior to Sand Casting in dimensional accuracy and surface finish (Sand casting’s advantage lies in producing very large, simple parts at the lowest material cost).

Compared to Die Casting (which specializes in extremely high-volume aluminum and zinc parts), investment casting’s advantage is its ability to support a broader range of high-temperature metals and more complex geometries.

Conclusion

Investment casting plays a core role in modern manufacturing as a precision solution. Its capability to combine complex geometry delivery with high-performance alloys makes it an important process choice for critical components in high-precision sectors.

Need Precision Investment Casting Support?

If your project requires the accuracy and finish of precision investment casting, contact our engineering team for a feasibility assessment, process selection reference, and a free quote.