What is Ferritic Stainless Steel?

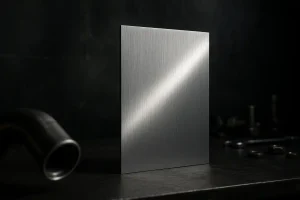

Simply put, ferritic stainless steel is a high-chromium, low-carbon, nickel-free alloy. Unlike common austenitic stainless steels (like 304), ferritic stainless steel is distinctly magnetic due to its specific crystal structure and can be attracted by a magnet. This unique composition and structure give it excellent corrosion resistance and oxidation resistance while avoiding the high cost of nickel.

For this reason, ferritic stainless steel has become the preferred material for various applications, including automotive exhaust systems, household appliances, and kitchen utensils.

Key Components

The performance of ferritic stainless steel is rooted in the precise proportion of its key elements:

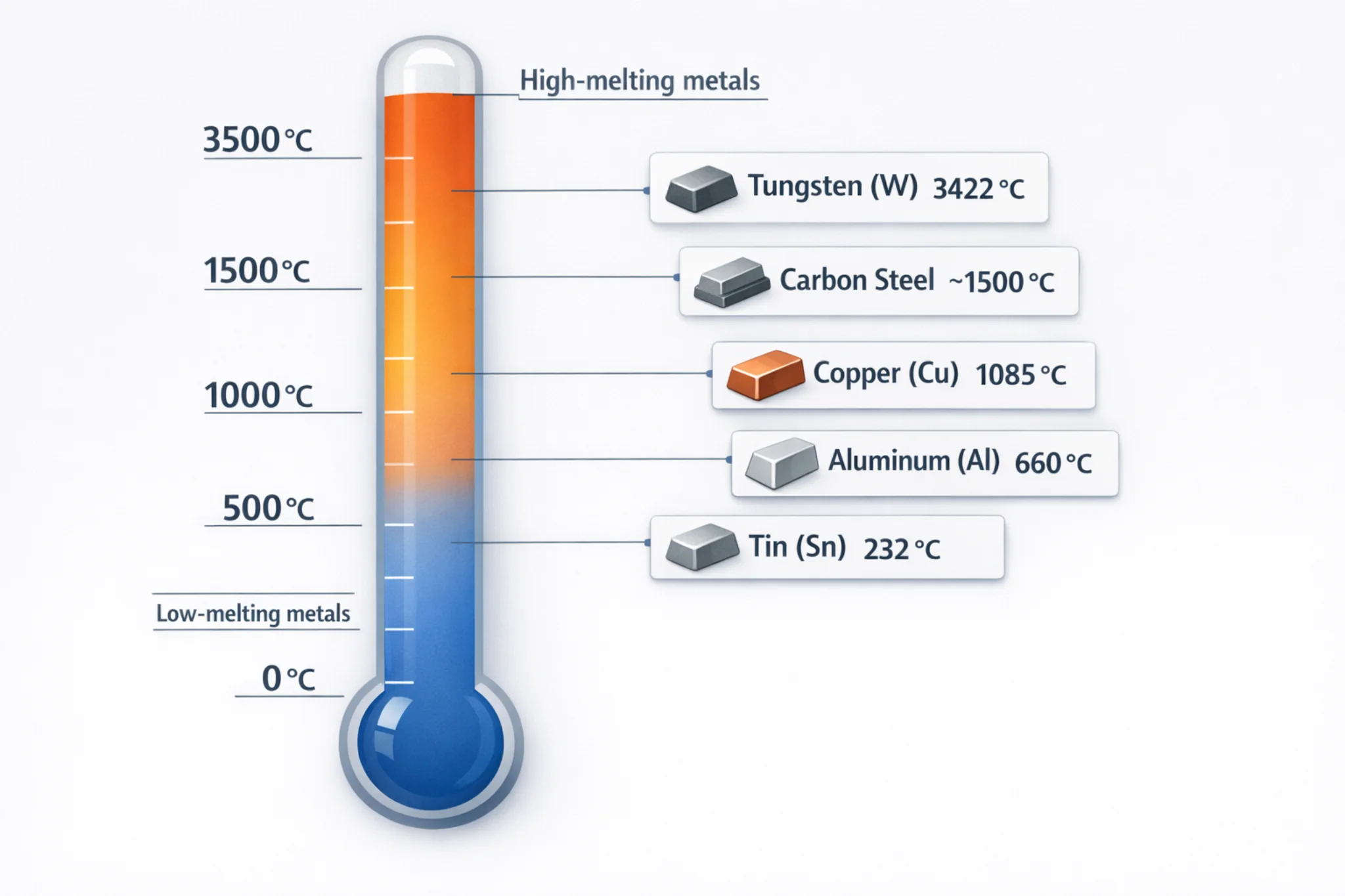

- Chromium (Cr): This is the most important alloying element in ferritic stainless steel, with a content typically ranging from 10.5% to 27%. Chromium is crucial for forming the dense, self-healing chromium oxide passivation layer (the reason it’s “stainless”). Higher chromium content leads to better corrosion resistance.

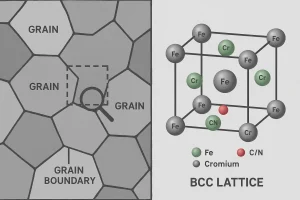

- Carbon (C): The carbon content of ferritic stainless steel is very low, usually below 0.1%. This low carbon content ensures a stable Body-Centered Cubic (BCC) crystal structure, providing good ductility and weldability while reducing brittleness during processing.

- Nickel (Ni): This is the biggest difference between ferritic and austenitic stainless steels. Ferritic stainless steel is essentially nickel-free, which not only gives it magnetic properties but also significantly lowers material costs and effectively prevents stress corrosion cracking.

- Other Alloying Elements: Some advanced grades may include Molybdenum (Mo) to enhance resistance to pitting and crevice corrosion, or Titanium (Ti) and Niobium (Nb) to stabilize carbon and nitrogen, further improving weldability.

Microstructure and History

- Microstructure: The core of ferritic stainless steel is its Body-Centered Cubic (BCC) crystal structure, which gives it good thermal conductivity and magnetic properties. However, it also makes it less ductile and tough compared to austenitic stainless steel.

- History: The origin of ferritic stainless steel can be traced back to the early 20th century, where it was initially used for cutlery. With advances in metallurgy, especially the development of extra-low carbon ferritic stainless steel, its corrosion resistance and weldability have significantly improved, and its application scope has rapidly expanded to include automotive, home appliances, and other broader fields.

Core Physical Properties

The physical properties of ferritic stainless steel give it significant advantages in thermal management and cost control. The table below lists typical physical property data for some common grades, measured at room temperature (approx. 20°C):

| Grade | Thermal Conductivity (W/m·K) | Coefficient of Thermal Expansion (10⁻⁶/°C) | Modulus of Elasticity (GPa) | Specific Heat Capacity (J/kg·K) |

| 409 | 25 | 11.0 | 200 | 460 |

| 430 | 26 | 10.4 | 220 | 460 |

| 439 | 26.8 | 11.2 | 220 | 427 |

| 441 | 24 | 10.9 | 220 | 430 |

| 444 | 26.8 | 11.0 | 220 | 427 |

| 446 | 27.5 | 11.5 | 220 | 450 |

| Austenitic 304 | 16.2 | 17.2 | 193 | 500 |

Note: Data for austenitic 304 stainless steel is included for comparison, highlighting the high thermal conductivity and low thermal expansion of ferritic stainless steel.

Ferritic Stainless Steel Grades and Applications

There are numerous grades of ferritic stainless steel, typically classified by their composition and performance differences. The table below lists some common grades and their typical applications:

| ASTM/AISI | GB Standard | Main Elements | Key Characteristics | Typical Applications |

| 409 | 00Cr11Ti | Cr, Ti | Good high-temperature resistance, good weldability | Automotive exhaust systems, catalytic converters |

| 430 | 1Cr17 | Cr | Most common, general-purpose grade with good corrosion resistance and cost-effectiveness | Home appliances, kitchen utensils, architectural trim |

| 434 | 01Cr17Mo | Cr, Mo | Molybdenum modified, strong resistance to pitting and crevice corrosion | Water heater inner tanks, roofing, outdoor architecture |

| 436 | 00Cr18MoTi | Cr, Mo, Ti | Excellent corrosion resistance and formability | Washing machine drums, automotive trim |

| 439 | 00Cr18Ti | Cr, Ti | Titanium stabilized, improved weldability and thermal expansion | Automotive exhaust pipes, furnace heat exchangers |

| 441 | 00Cr18NbMo | Cr, Nb, Mo | Dual stabilized, excellent weldability, higher heat resistance | Kitchen equipment, automotive exhaust pipes, heat exchangers |

| 444 | 00Cr18Mo2 | Cr, Mo, Ti/Nb | High-grade molybdenum modified, far superior corrosion resistance than 430 | Solar collectors, water tanks, heat exchangers |

| 446 | 1Cr25 | Cr | High chromium content, excellent oxidation resistance | Industrial furnace parts, high-temperature heat exchangers |

Why Choose Us?

In the field of precision processing of ferritic stainless steel, professional knowledge and extensive practical experience are essential. We not only have a deep understanding of this material’s properties but also possess the expertise to overcome its processing challenges.

No matter what your project’s requirements are for cost, durability, or specific performance, we can provide the ideal solution through professional material selection and exquisite processing technology.

Choose us to turn your ideas into reality. Contact our professional team now to get a customized solution and embark on your next precision project together.

Frequently Asked Questions

What are the processing challenges of ferritic stainless steel?

The main drawback of ferritic stainless steel is its brittleness. Due to its low carbon content, it can become more brittle during high-temperature welding and is prone to cracking when forming complex shapes. Our professional technology allows for precise control of processing parameters, effectively avoiding these issues.

What is the difference between ferritic and austenitic stainless steel?

The main differences between these two types of stainless steel are their composition, magnetism, and applications. Ferritic stainless steel is nickel-free and magnetic, often used in applications where cost and high-temperature resistance are key. Austenitic stainless steel contains nickel and is non-magnetic, and is used in a wider range of applications.

Does ferritic stainless steel rust?

Yes, any stainless steel can rust if used in an inappropriate environment. Ferritic stainless steel resists corrosion through its chromium oxide layer on the surface. Under normal use conditions, its corrosion resistance is sufficient for most applications.