In modern metal manufacturing, centrifugal casting has become a preferred and essential process for producing dense, high-integrity cylindrical components.

By utilizing the centrifugal force generated by mold rotation, molten metal is tightly compacted against the mold walls and solidifies directionally, resulting in parts with excellent mechanical strength and minimal internal defects.

This technique is especially suitable for the production of tubes, bushings, rings, and sleeves required in the automotive, energy, and machinery industries.

What Is Centrifugal Casting

Centrifugal casting is a metal casting process in which molten metal is poured into a rapidly rotating mold.

The centrifugal force drives the metal toward the mold walls, forming a compact, homogeneous structure as it cools from the outside inward.

Unlike gravity casting, centrifugal casting does not rely on risers or feeders; the rotational acceleration ensures even distribution and self-compaction of the molten metal.

This achieves superior density, minimal inclusions, and high mechanical performance—making it ideal for demanding engineering applications.

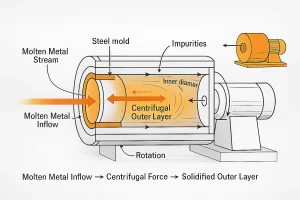

How Centrifugal Casting Works

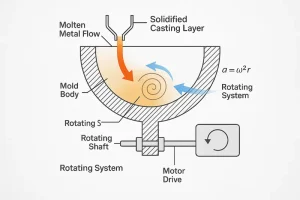

The core principle of centrifugal casting is to use rotational acceleration to drive molten metal toward the mold walls.

Diagram showing how molten metal forms a dense outer layer inside a rotating mold during the centrifugal casting process.

When the mold spins at high speed, the metal experiences centrifugal acceleration (a=ω2r), which causes dense material to move outward while lighter impurities and gases migrate toward the center. Solidification proceeds from the outer wall inward, resulting in a fine-grained, directionally solidified structure with enhanced fatigue and tensile strength.

Process Steps and Operational Highlights

Each stage of centrifugal casting—from mold preparation to machining—critically affects the final product’s integrity and dimensional accuracy.

1. Mold Preparation

Molds are typically made of steel or graphite and coated with a refractory lining to prevent metal adhesion. Preheating the mold to a controlled temperature removes moisture and reduces thermal shock during pouring.

2. Metal Melting and Pouring

The alloy is melted to the target temperature and poured into the rotating mold through a ladle or pouring tube. Rotation speed must be precisely matched to the metal type to ensure smooth, uniform distribution along the mold wall.

3. Solidification and Cooling

Cooling begins at the mold wall and progresses inward. Continuous rotation compacts the metal structure, while conversely, improper cooling can cause segregation or wall-thickness variation.

4. Extraction and Machining

After solidification, the mold stops spinning and the casting is removed. The inner layer, which typically contains gases or oxides, is machined away to achieve precise dimensions and a clean surface.

Metal molds are reusable for dozens or hundreds of cycles, making centrifugal casting highly effective and sustainable for continuous production. Although the initial equipment cost is relatively high, long mold life and minimal material waste make the process cost-effective for medium- and large-scale operations.

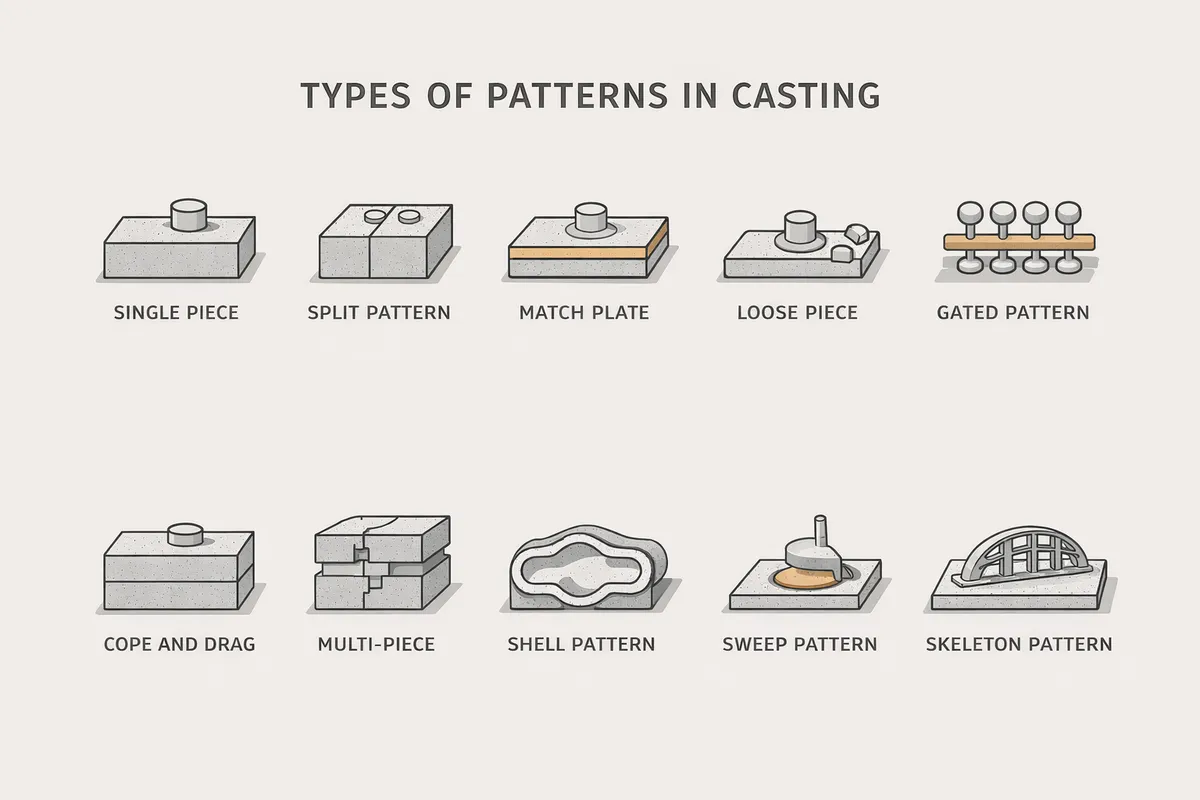

Types of Centrifugal Casting

Centrifugal casting systems are generally categorized by mold orientation and motion characteristics.

1. Horizontal Centrifugal Casting

The mold’s axis lies horizontally, ideal for pipes, sleeves, and cylindrical bushings. This configuration ensures uniform wall thickness and is the most widely used setup in industry.

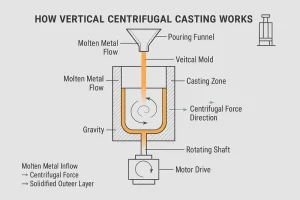

2. Vertical Centrifugal Casting

The mold’s axis is vertical, with molten metal poured from the top.

Schematic line diagram illustrating the working principle of vertical centrifugal casting.

Centrifugal and gravitational forces combine, making it suitable for rings, gear blanks, and pump housings.

3. Semi-Centrifugal Casting

This method partially relies on centrifugal force and is typically used for thicker or near-solid parts such as impellers and pulleys.

Technical line diagram illustrating the working principle of semi-centrifugal casting.

It offers a balance between material density and equipment cost.

Materials Suitable for Centrifugal Casting

Centrifugal casting is compatible with a broad range of ferrous and non-ferrous alloys, each requiring specific speed and temperature control parameters.

1. Gray Iron and Ductile Iron

These iron-based alloys offer excellent fluidity and cost efficiency. Gray iron provides good damping capacity for components like pump bodies and brake drums, while ductile iron offers better toughness for pressure-bearing parts.

2. Carbon and Stainless Steel

Both steels perform well in high-pressure, high-temperature, or corrosive environments. Carbon steel offers high strength and low cost, whereas stainless steel provides superior oxidation and corrosion resistance. Tight control of pouring temperature and cooling rate is paramount to prevent cracking or segregation.

3. Copper and Copper Alloys

Copper, bronze, and brass deliver excellent thermal conductivity and wear resistance. Centrifugal casting produces dense, defect-free surfaces suitable for bearings, sealing rings, and guide sleeves.

4. Aluminum Alloys

Aluminum alloys are lightweight and corrosion-resistant, ideal for thin-walled and heat-dissipating components. Careful control of mold preheating and rotation speed prevents cold shuts and gas entrapment.

5. Nickel- and Cobalt-Based Superalloys

Used in turbine rings and combustion liners, these materials require vacuum or controlled-atmosphere casting. Centrifugal casting provides fine-grained, high-purity structures for extreme service conditions.

Advantages of Centrifugal Casting

Centrifugal casting offers several key advantages in terms of strength, efficiency, and precision:

-

High density and strength: Centrifugal force compacts molten metal tightly against the mold wall, reducing porosity and increasing tensile and fatigue strength.

-

Excellent material utilization: No risers or cores are required, allowing more than 90% metal yield and less machining waste.

-

Refined grain structure: Solidification from the outside inward creates fine, directional grains that enhance wear and fatigue resistance.

-

Dimensional precision: Uniform rotation keeps wall thickness consistent and dimensional tolerances tight.

-

Production efficiency: Once equipment is calibrated, the process delivers consistent quality with minimal scrap and shorter cycle time, offering strong long-term productivity.

Disadvantages of Centrifugal Casting

Although centrifugal casting provides excellent quality, it also presents several limitations:

-

Restricted shape range: The process suits only cylindrical or ring-shaped parts and cannot produce complex geometries.

-

Sensitive process control: Rotation speed, pouring temperature, and cooling rate must be precisely regulated to avoid segregation or layering.

-

Inner-surface machining required: Impurities collect near the bore and must be removed by machining.

-

High equipment cost: The machinery is expensive and complex, making the process less practical for short-run production.

Typical Applications of Centrifugal Casting

Centrifugal casting is widely used where high strength, uniformity, and cost control are critical:

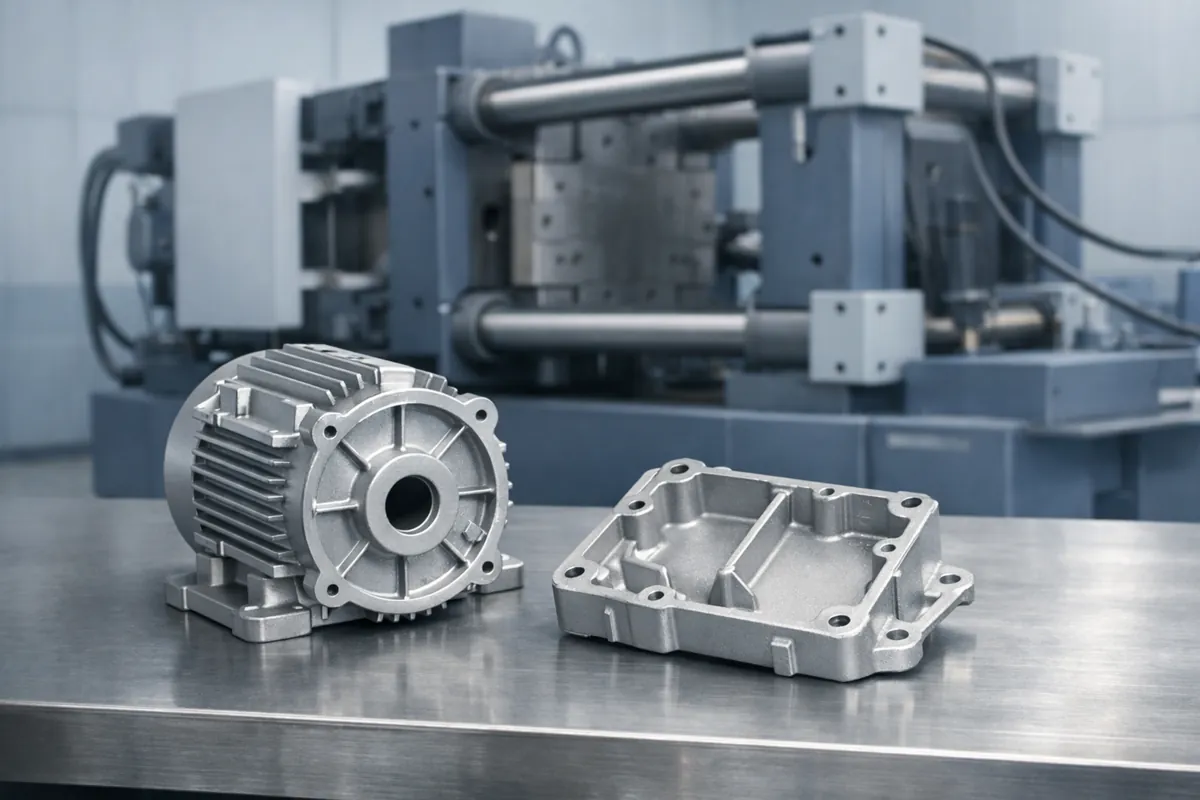

A selection of finished centrifugal cast components, including heavy-duty bushings and rings, showcasing dense structure and precise machining.

-

Aerospace: Turbine rings, sealing rings, and other high-temperature parts produced under vacuum for maximum purity.

-

Automotive: Cylinder liners, brake drums, and piston rings requiring excellent wear resistance.

-

Machinery: Bushings, sleeves, pulleys, and flywheels that demand balance and dimensional stability.

-

Energy and chemical industries: Pump housings, valve seats, and pressure components exposed to heat and stress.

Comparison with Other Casting Processes

| Process Type | Key Characteristics |

| Sand Casting | Low cost and flexible for complex shapes, but often results in lower density, higher porosity, and surface defects. |

| Investment Casting | Excellent dimensional accuracy and surface finish, yet slower and more expensive for large cylindrical parts. |

| Centrifugal Casting | Achieves high density, fine-grained structure, and uniform wall thickness — ideal for tubes, rings, and sleeves. |

Centrifugal casting effectively bridges the gap between strength and precision. While sand and investment casting each have their niche, centrifugal casting delivers the best balance of density, mechanical integrity, and production efficiency for rotationally symmetrical parts.

FAQ about Centrifugal Casting

Q1: What types of centrifugal casting machines exist?

There are two main machine orientations—horizontal and vertical. Horizontal machines are suited for long cylindrical parts such as pipes and sleeves, while vertical machines handle rings, gear blanks, and heavy components where gravity assists filling. Semi-centrifugal machines are used for thicker solid parts like pulleys or impellers.

Q2: How is operator safety ensured during centrifugal casting?

Modern systems include vibration sensors, automatic speed regulation, and interlocks that prevent metal pouring until the mold reaches the correct RPM. Proper PPE, mold preheating, and balance inspection are critical to prevent accidents from metal splash or imbalance.

Q3: How can you control quality and prevent defects?

Consistent rotation speed, stable pouring temperature, and mold alignment are the key factors. Advanced machines use programmable controllers (PLC) and real-time monitoring to maintain these parameters, reducing segregation and porosity.

Q4: Can centrifugal casting be combined with other processes?

Yes. It’s often followed by machining or heat treatment to refine tolerances or improve surface properties. In some cases, it’s integrated with investment or sand casting when only part of a component needs high density.

Q5: What are the long-term maintenance needs of a centrifugal casting machine?

Regular inspection of bearings, drive belts, and refractory coatings is essential. Lubrication and dynamic balance checks help extend mold and spindle life, ensuring consistent product quality over hundreds of production cycles.

Conclusion

Centrifugal casting combines centrifugal force and directional solidification to achieve a level of density and accuracy unmatched by traditional casting methods.

It remains a key process for producing high-performance metal components across automotive, energy, machinery, and aerospace sectors.

👉 Need help choosing the right casting process for your project? Our engineering team can provide expert guidance. Contact Minghe Engineers →