In the world of custom non-standard part manufacturing, the choice of a production method is a critical decision that impacts performance, cost, and delivery time. We often find ourselves weighing the two core technologies: casting and machining. A true professional insight, however, lies not in choosing one over the other, but in understanding their unique strengths and finding the perfect synergy between them.

These two are not simply competing technologies but rather complementary strategic partners. They typically work in a specific sequence: first, casting gives a part its complex macro-form and cost-effectiveness; then, machining refines it to achieve impeccable precision. This approach allows for more competitive costs and shorter lead times while still meeting high-precision requirements.

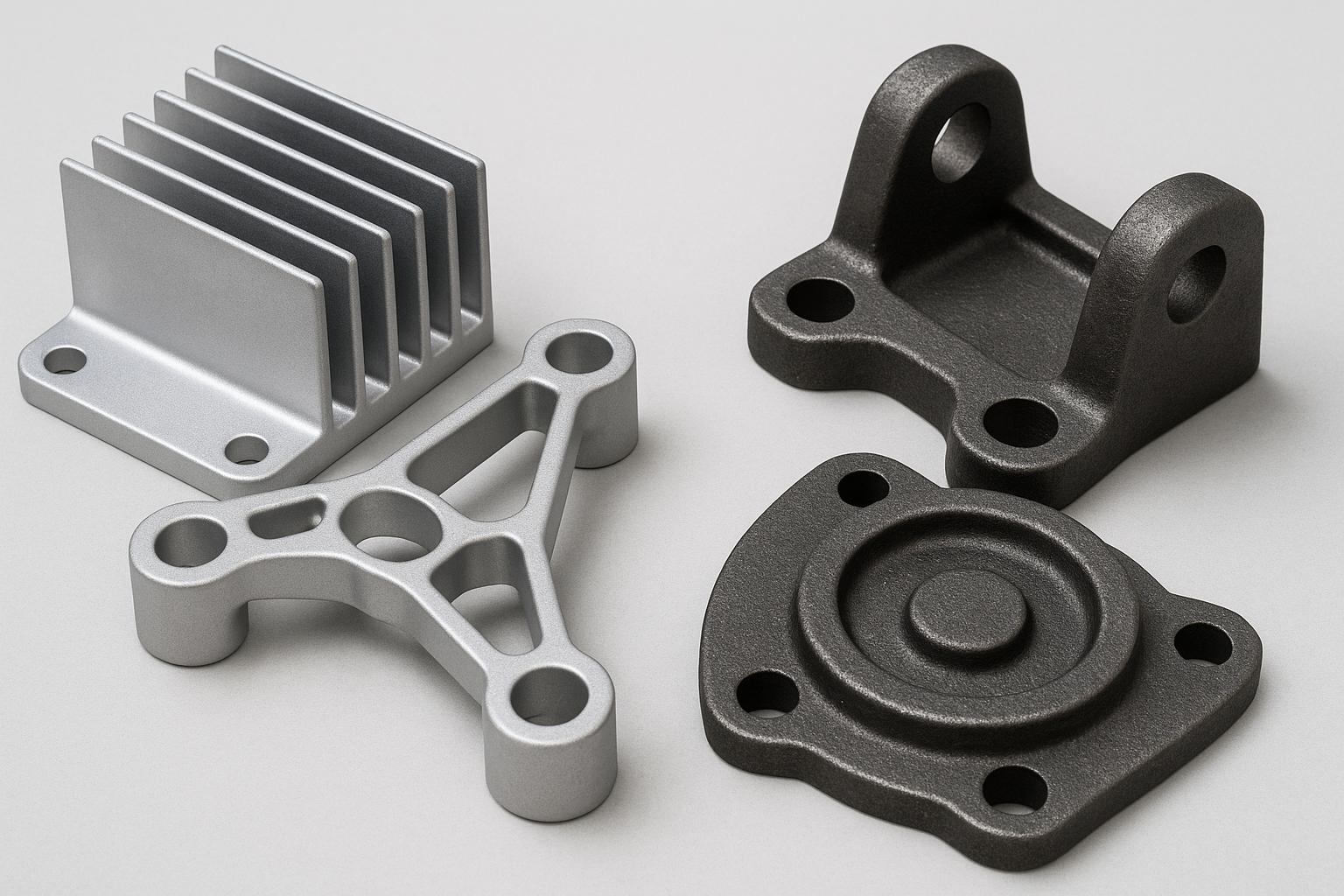

What is Casting?

Casting is an “additive” or “liquid-forming” process. It works by heating metal to a molten state and pouring it into a pre-made mold, where it cools and solidifies into the final part. This process is particularly well-suited for manufacturing non-standard parts with complex geometry.

Pros and Cons of Casting

Advantages of Casting

Champion of Cost and Scale Casting’s unique value lies in its ability to transform high initial mold investment into an extremely low per-piece cost. This makes casting the ideal choice for large-scale manufacturing. When you need thousands of complex parts, casting can achieve mass production with the highest efficiency and lowest cost, significantly saving your project’s budget.

Breakthrough Design Limitations Casting is the only way to achieve certain complex geometries. It can create parts with intricate internal passages, hollow structures, or irregular curves in a single step. This not only simplifies your design but also avoids potential risks from subsequent welding and assembly, ensuring the part’s integrity and reliability.

Extensive Material Selection From lightweight aluminum alloys and durable ductile iron to corrosion-resistant stainless steel, casting can process a wide range of metals and alloys. This gives you immense flexibility, ensuring your part can be made from the most suitable material to meet specific performance needs (e.g., strength, wear resistance, corrosion resistance).

Disadvantages of Casting

Lower Dimensional Accuracy Due to metal shrinkage during solidification, cast parts typically have larger dimensional tolerances and cannot meet high-precision requirements. Most castings require subsequent machining to achieve the final dimensions and mating requirements.

Poor Surface Finish Cast surfaces are generally rough, with defects like sand holes and burrs. If a product requires a good appearance or specific surface performance, it must undergo secondary processes like grinding, sandblasting, or machining to improve it.

Risk of Internal Defects During the casting process, internal defects such as pores and shrinkage can occur due to air bubbles or uneven contraction. These internal flaws are not visible to the naked eye and require non-destructive testing, such as X-ray or ultrasonic inspection, to ensure quality.

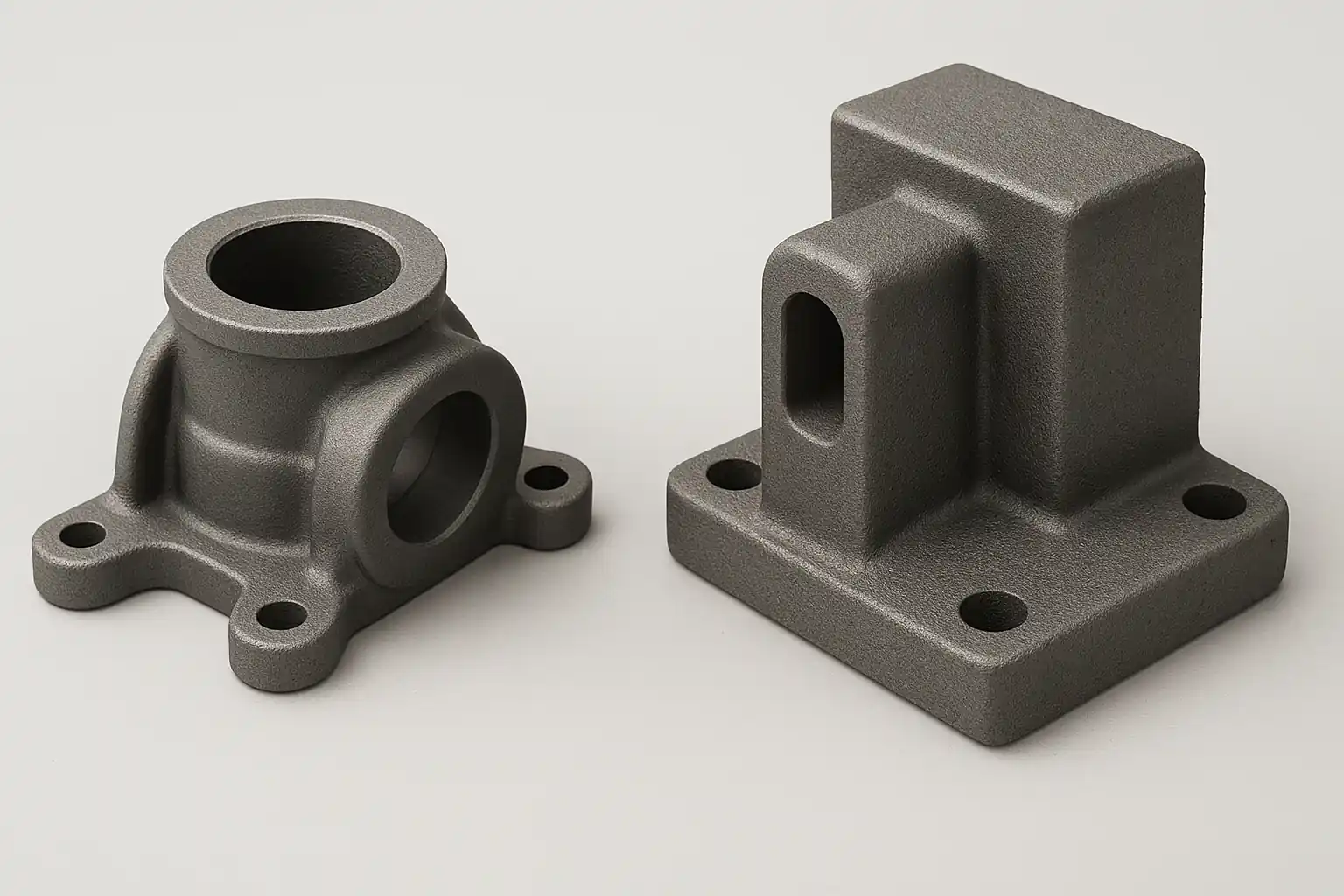

Main Types of Casting

Sand Casting

This is the oldest, most versatile, and most cost-effective casting method. It uses reusable sand as the mold material.

- Key Features: Extremely low tooling costs, making it ideal for producing large, complex parts in small production volumes.

- Typical Applications: Automotive engine blocks, heavy machinery bases and frames, and large pipe fittings.

Investment Casting

This is a “lost wax” process that can cast parts with exceptionally high precision. A wax pattern is first created, then coated with a refractory material. The wax is then melted out, leaving a precise hollow mold.

- Key Features: Exceptionally high dimensional accuracy, excellent surface finish, and the ability to cast intricate internal structures and fine details.

- Typical Applications: Aerospace components, medical devices, high-end valve parts, and complex small parts requiring tight tolerances.

Die Casting

This method uses high pressure to inject molten metal into a reusable metal mold.

- Key Features: Extremely high production speed and very low per-piece costs, as the mold can be used thousands of times. It’s perfectly suited for mass production.

- Typical Applications: Automotive parts (like engine covers), electronics casings, home appliance components, and non-ferrous parts that require fast, high-volume manufacturing.

Centrifugal Casting

This method uses centrifugal force to spin molten metal into a mold, ensuring uniform distribution and solidification.

- Key Features: Parts have a dense internal structure with no pores or inclusions, resulting in uniform and reliable performance.

- Typical Applications: Cylindrical or tubular parts like bushings, liners, and pipes.

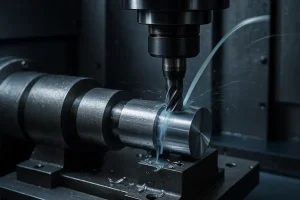

What is Machining?

Machining is a “subtractive” or “cutting” process. It uses cutting tools (such as milling cutters and lathes) to precisely remove material from a solid block, achieving strict dimensions and a smooth surface finish. Machining can be viewed as the process of “sculpting” a part to perfection.

Pros and Cons of Machining

Advantages of Machining

Unmatched Precision and Quality Machining is the top choice for achieving extreme precision and a perfect surface finish. It can easily meet micron-level tolerance requirements, ensuring the precise fit and reliability of a part’s critical functional areas. This high level of precision directly determines the final product’s performance, stability, and lifespan.

Exceptional Flexibility and Agility Unlike casting, machining requires no molds, which significantly reduces initial investment and modification costs. It is ideal for rapid prototyping and customized small-batch production. When designs need quick iteration or market demands shift, machining can respond swiftly, drastically shortening the product’s cycle from design to delivery.

Broad Material Compatibility Machining can handle almost all types of metals, including special high-strength alloys that are difficult or impossible to cast. This gives engineers the freedom to choose the most suitable material for the part’s demanding working conditions, ensuring optimal performance.

Disadvantages of Machining

High Material Waste Machining is a “subtractive” process that cuts the final shape from a solid block of material. For complex parts, this generates a large amount of scrap, leading to low material utilization and increased costs.

Unsuitable for High-Volume Mass Production Machining is a subtractive process that removes material layer by layer. Compared to the one-time, bulk replication capability of casting, when part quantities reach tens of thousands or more, the per-piece cost and total production time for machining increase dramatically, making it unsuitable for ultra-high-volume manufacturing scenarios.

Unsuitable for Complex Internal Structures Machining is limited by the size and movement of cutting tools, making it unable to easily create parts with complex internal passages or hollow cavities like casting can. To achieve these structures, multiple parts often need to be machined and then welded or assembled, which adds complexity and cost.

Main Types of Machining

Turning

This process uses a lathe to cut a rotating workpiece, primarily for creating cylindrical, conical, and threaded parts.

- Key Features: Highly efficient for processing rotationally symmetric parts, capable of achieving a good surface finish.

- Typical Applications: Shafts, bolts, pins, flanges, and various threaded components.

Milling

Milling uses a rotating cutting tool to machine a stationary or moving workpiece, allowing for the creation of flat surfaces, grooves, curves, and complex shapes.

- Key Features: Highly versatile, capable of machining various complex 3D geometries.

- Typical Applications: Mold cavities, machine brackets, cams, and various complex contoured parts.

Drilling

Drilling uses a rotating cutting tool to create circular holes in a workpiece. It is often the first step for subsequent processes like tapping or reaming.

- Key Features: Provides a quick and efficient way to create holes in a part.

- Typical Applications: Mounting holes, thread pilot holes, and various through-holes.

Grinding

Grinding uses a high-speed abrasive wheel to remove a small amount of material from a workpiece. It is typically the final process.

- Key Features: Capable of achieving extremely high dimensional accuracy and a superior surface finish, while eliminating previous machining marks.

- Typical Applications: Bearing mating surfaces, precision shafts, gauges, and surfaces requiring a mirror finish.

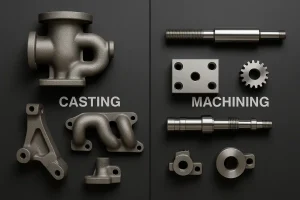

Core Differences Between Casting and Machining

Working Principle

Casting is an additive process that forms parts by adding material to a mold. Machining is a subtractive process that removes material from a solid block. This fundamental difference affects material utilization and production efficiency.

Production Cost Model

Casting is characterized by high mold costs but low piece costs. Machining has low (or zero) tooling costs but high piece costs. This makes casting ideal for mass production, while machining is better for small batches and prototypes.

Dimensional Accuracy and Surface Finish

Casting typically has lower dimensional accuracy with wider tolerances and a rougher surface finish. Machining can achieve extremely high precision, often to the micron level, and provides a superior surface finish.

Design Freedom

Casting offers greater design freedom, enabling the creation of complex internal structures, hollow cavities, and integrated features that are difficult or impossible to machine. Machining’s design freedom is limited by the geometry and movement of the cutting tools.

Final Material Properties

Cast parts often have an irregular grain structure from the solidification process, which can lead to non-uniform mechanical properties. Machined parts, typically made from forged or rolled stock, have a denser and more uniform grain structure, resulting in more consistent strength and toughness.

Quality Control Focus

Quality control for casting focuses on detecting internal defects like pores and shrinkage, often using non-destructive testing (X-ray, ultrasound). For machining, the focus is on measuring external dimensions and geometric tolerances (flatness, concentricity), typically with a Coordinate Measuring Machine (CMM).

Application of Each Process in Different Industries

Different industries have unique requirements for part performance, precision, and cost, which directly determines the choice between casting and machining.

Generally, casting excels at producing large or structurally complex parts, such as automotive engine blocks and valve bodies, thanks to its cost-effectiveness and ability to form complex geometries. Machining, on the other hand, is the top choice for manufacturing precision parts with strict dimensional tolerances, like aerospace turbine blades and high-precision pistons, due to its superior precision and excellent surface finish.

| Industry | Typical Cast Parts | Typical Machined Parts |

| Automotive | Engine blocks, transmission housings, wheel hubs, exhaust manifolds | Camshafts, crankshafts, gears, high-precision pistons |

| Pump & Valve | Valve bodies, pump casings, impellers, flanges | Valve stems, seats, precision shafts, seals, high-precision bores |

| Heavy Machinery | Excavator tracks, machine frames, gearboxes, large enclosures | Hydraulic pistons, precision shafts, connectors, control valves |

| Energy | Wind turbine hubs, bases, generator housings | Turbine blades, bearing housings, high-precision gears |

| Aerospace | Engine turbine casings, brackets, structural components | Turbine blades, precision shafts, connectors, critical fasteners |

| Medical | Surgical instrument handles, equipment housings, brackets | Micro orthopedic implants, surgical blades, precision joints, sensor enclosures |

| Construction | Pipe fittings, water pump casings, large structural connectors | Specialized bolts, nuts, high-precision fittings |

Casting vs. Machining: How to Choose

Choosing the right manufacturing process is not about finding a single “best” solution, but rather the most suitable one for your specific project. The optimal choice often lies in a combined approach, leveraging the strengths of each technology. To make a confident decision, consider the following key factors:

- Part Complexity & Geometry: Does the part have intricate internal passages, hollow sections, or complex curves that would be difficult to cut? If yes, casting is the foundational solution. If the part is solid with simple, external features, it can be machined directly.

- Production Volume & Cost: Are you producing a single prototype or tens of thousands of parts? For low-volume production or one-off parts, machining is often the most cost-effective choice due to its low initial setup cost. For large-scale production, casting’s low per-piece cost makes it the clear winner, despite the higher upfront tooling investment.

- Precision & Surface Finish: Does the part require extremely tight dimensional tolerances or a smooth, high-quality surface for mating or sealing? If yes, machining is essential. While casting provides the rough shape, machining provides the critical precision and finish needed for functional performance.

- Material Selection: Do you need a material that is difficult to machine, or do you need the uniform grain structure that comes from a forged material? Casting gives you more options for materials that are challenging to machine, while machining offers superior properties from specific alloys.

Ultimately, for most high-performance industrial parts, the ideal solution is a hybrid approach. By first casting a near-net-shape part and then using precision machining to finish critical features, you get the best of both worlds: the cost-effectiveness and design freedom of casting, combined with the unparalleled accuracy and quality of machining.

Conclusion

In short, casting and machining are not competing technologies but rather strategic partners. Casting excels at macro-forming, providing complex shapes and cost advantages, while machining specializes in micro-finishing, ensuring indispensable precision. By combining both, you can find the most optimal and cost-effective manufacturing path for your non-standard parts.

Contact Us

As a professional supplier of non-standard cast parts, we are dedicated to providing a one-stop solution. Our engineering team can assist you from the design phase to plan the most rational “cast + machine” solution. No matter how complex your project is, we ensure your products achieve the best balance of performance, cost, and delivery.

Contact us today for a customized casting and machining solution.