Introduction

Sand casting is one of the most widely used metal casting processes due to its versatility, simplicity, and cost-effectiveness. It involves using a sand mold to shape molten metal into a desired form, making it especially suitable for both small-batch production and large-scale industrial components.

What Is Sand Casting

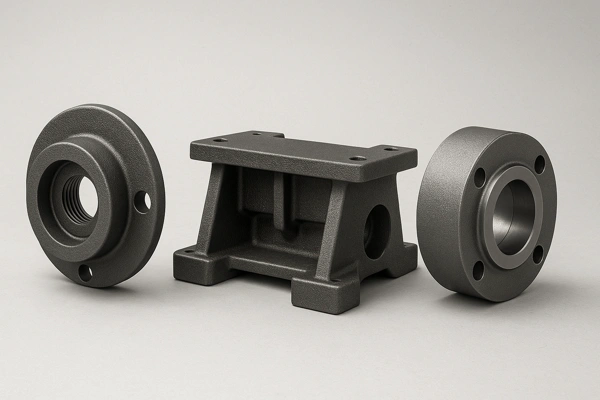

Sand casting is a manufacturing technique where molten metal is poured into a cavity formed by a sand mold. The mold is created by packing special sand around a pattern that matches the shape of the final part. After removing the pattern, molten metal is poured into the cavity. Once cooled, the sand mold is broken to reveal the finished casting.

This method works with a wide range of metals, including iron, steel, aluminum, and brass.

Advantages of Sand Casting

- Low tooling and mold-making costs

- Compatible with most ferrous and non-ferrous metals

- Ideal for producing large or complex parts

- Flexible for both prototyping and production runs

Limitations of Sand Casting

- Rougher surface finish compared to precision methods

- Lower dimensional accuracy

- May require secondary machining

Applications

- Machine bases

- Pump housings

- Engine blocks

- Custom industrial components

Comparison Table

| Casting Method | Cost | Strength | Precision | Best Applications |

|---|---|---|---|---|

| Sand Casting | ⭐⭐ | ⭐⭐⭐ | ⭐ | Prototypes, machine bases, large parts |

| Steel Casting | ⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | Mining tools, valves, heavy-duty parts |

| Iron Casting | ⭐⭐ | ⭐⭐⭐ | ⭐⭐ | Auto parts, manhole covers, machine frames |

| Aluminum Casting | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ | Brackets, electronics, lightweight mechanical parts |

Conclusion

Sand casting remains a cost-effective and versatile solution for producing metal parts. By understanding its benefits and limitations, and comparing it with other casting methods like steel, iron, and aluminum casting, manufacturers can make informed decisions based on their specific requirements.

👉 Learn more about our services: Visit our casting services page