Aluminum is widely recognized for its resistance to corrosion, but many engineers and buyers still wonder whether it can “rust” in the same way that iron or steel does. The confusion is understandable—both aluminum and steel are metallic structural materials, and both can deteriorate under certain environmental conditions. However, the mechanisms behind this deterioration are fundamentally different. Before examining how aluminum behaves, it is essential to understand what “rust” actually means from a metallurgical and electrochemical standpoint.

What Is Rust?

Rust is a term specifically referring to the electrochemical reaction that occurs when ferrous metals—such as iron and steel—are exposed to oxygen and moisture. Chemically, rust is the oxidation of iron, forming hydrated iron oxide (Fe₂O₃·nH₂O), a loose, porous, and brittle reddish-brown substance. This oxide layer is not protective; instead, it continually flakes away from the surface, exposing new iron underneath and allowing corrosion to progress deeper into the material. This self-accelerating deterioration explains why rust can rapidly compromise the structural integrity of iron-based metals and why aluminum, which contains no iron, behaves in a fundamentally different way.

Does Aluminum Rust

No. Strictly speaking, aluminum does not rust because “rusting” specifically denotes the oxidation of iron. Aluminum does not contain iron elements and therefore cannot form hydrated iron oxide. However, this does not mean aluminum is absolutely immune to corrosion. Like all active metals, aluminum undergoes oxidative corrosion when exposed to air. But unlike iron, aluminum’s oxide—aluminum oxide ($\text{Al}_2\text{O}_3$)—is stable and possesses self-protective properties.

How Aluminum Corrodes

Aluminum’s unique resistance to atmospheric degradation is fundamentally rooted in its intrinsic chemical reaction with oxygen, which immediately creates a protective layer.

Natural Oxide Film

When a fresh aluminum surface is exposed to air, it reacts instantaneously with oxygen, forming an extremely thin, dense, and non-porous layer of aluminum oxide ($\text{Al}_2\text{O}_3$). The thickness of this protective film is typically only $2 \text{–} 10 \text{ nanometers}$. This natural oxide film is highly chemically inert and effectively prevents oxygen and moisture from contacting the underlying metal substrate, which largely inhibits further corrosion. This self-passivating film is what gives aluminum its excellent corrosion resistance.

When Corrosion Occurs

Despite the protection offered by the natural oxide film, aluminum corrosion can still occur under certain extreme conditions:

- High or Low pH Environments: The aluminum oxide film is unstable in strong acid (pH below 4) or strong alkali (pH below 9) environments, where it can be dissolved. Once the protective film is compromised, the aluminum substrate is exposed, accelerating corrosion.

- Presence of Halide Ions: Chloride ions ($\text{Cl}^-$), particularly common in seawater or salty environments, can penetrate or destroy the oxide film, initiating pitting corrosion.

- High Temperature and Humidity: Although corrosion is slow initially, the rate increases in hot and humid conditions.

- Galvanic Effect: When aluminum is coupled with a more noble metal (such as copper, nickel, or steel), aluminum acts as the anode and preferentially corrodes.

Common Corrosion Forms

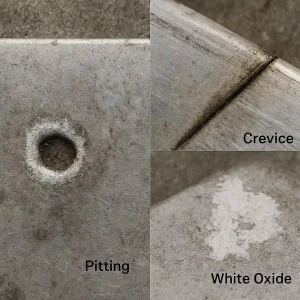

Aluminum’s most common corrosion forms include:

- Pitting Corrosion: This is the most common and often destructive form of aluminum corrosion. Halide ions like chloride create small localized holes in the oxide film, and the corrosion penetrates deeply, forming tiny, deep pits.

- Crevice Corrosion: Occurs in narrow gaps between aluminum and another metal or non-metal material. Differences in oxygen concentration break down the oxide film within the crevice, creating a local anode where corrosion occurs.

- Galvanic Corrosion: When aluminum is in direct contact with a noble metal (like copper or stainless steel) in the presence of an electrolyte (water or moisture), aluminum sacrifices itself as the active metal to protect the noble metal.

- Exfoliation: Common in high-strength aluminum alloys with directional grain structures, corrosion spreads along grain boundaries parallel to the surface, causing the metal to layer or flake off.

What Aluminum Corrosion Looks Like

When aluminum corrodes, its appearance differs significantly from iron rust:

- White Powdery Substance: Aluminum corrosion products are mainly aluminum hydroxide or aluminum oxide, appearing as loose, white or off-white powdery spots or scale adhering to the surface.

- Peeling or Blistering: Severe exfoliation or pitting may lead to minor blistering or peeling of the coating or substrate surface.

- Non-Spreading Nature: Unlike rust, which continuously spreads, the corrosion products, once formed, tend to remain localized around the point of corrosion and spread very slowly unless removed mechanically or chemically.

- Dull Surface: In the initial stages of corrosion, aluminum’s luster decreases, and the surface becomes dull and tarnished.

Aluminum vs Iron vs Steel

To fully appreciate the corrosion resistance of aluminum, it is essential to first understand how its fundamental chemical behavior contrasts with that of common ferrous metals.

Rust Behavior

Aluminum corrosion is chemically the formation of aluminum oxide ($\text{Al}_2\text{O}_3$), which is a dense, hard, self-passivating protective film that causes corrosion to cease. Visually, aluminum corrosion appears as white or off-white powdery spots. In contrast, the rusting of iron and steel refers to the formation of hydrated iron oxide ($\text{Fe}_2\text{O}_3 \cdot n\text{H}_2\text{O}$), a porous substance that offers no protection and continuously flakes off, causing the corrosion to penetrate deeper until the metal is completely consumed. Iron rust has a characteristic reddish-brown appearance.

Corrosion Resistance

In most natural atmospheric environments, the overall corrosion resistance of aluminum is significantly superior to that of unprotected carbon steel and pure iron. This is because aluminum relies on its self-passivating film to establish an effective barrier right from the initial phase of corrosion. Carbon steel and iron lack this inherent protective mechanism and require external measures like galvanizing or coating to achieve comparable corrosion resistance to aluminum. However, in high-chloride environments or strong alkali/strong acid conditions, specialized surface treatments (such as anodizing) are necessary for aluminum to maintain its superior corrosion resistance.

How to Protect Aluminum from Corrosion

Preventing aluminum corrosion focuses on preserving and enhancing its natural oxide film.

Surface Coatings

Artificially enhancing the oxide film or adding an external coating is the most effective way to improve aluminum’s durability:

- Anodizing: This is the most common protective method. An electrochemical process forms a hard oxide layer on the aluminum surface that is hundreds of times thicker than the natural film, greatly enhancing corrosion and wear resistance.

- Liquid Painting: Applying high-performance coatings like epoxy or polyurethane creates an external physical barrier.

- Powder Coating: Provides a thick, abrasion-resistant, and VOC-free polymer film, particularly suitable for outdoor and industrial environments.

- Electrophoretic Coating: Suitable for parts with complex shapes, offering a uniform, thin film of protection.

Design & Usage

Appropriate design and environmental control can mitigate corrosion risks:

- Avoid Water Accumulation: Structural design should prevent moisture or electrolytes from accumulating in crevices.

- Isolate Galvanic Contact: Isolation must be used—such as gaskets or non-conductive coatings—where aluminum contacts noble metals (like copper or stainless steel) to prevent galvanic corrosion.

- Environmental Control: Avoid prolonged exposure to high chloride, highly acidic, or highly alkaline environments.

Material Selection

Choosing the right aluminum alloy helps resist corrosion in specific environments:

- Pure Aluminum (1xxx Series): Excellent corrosion resistance but low strength.

- 5xxx Series Alloys (Magnesium-containing): Exhibits high corrosion resistance, performing excellently in marine and saltwater environments.

- 2xxx and 7xxx Series Alloys (Copper/Zinc-containing): Typically high in strength but lower in corrosion resistance, usually requiring anodizing or coating for protection.

Conclusion

While aluminum does not “rust” like iron, it undergoes oxidative corrosion with a self-protective mechanism. Aluminum’s superior corrosion resistance stems from its surface’s dense aluminum oxide protective film. In modern manufacturing, advanced surface treatments like anodizing and powder coating are used to elevate aluminum’s resistance, ensuring its long-term, reliable application in diverse fields such as automotive, aerospace, construction, and electronics.

If you need corrosion-resistant cast aluminum components for your next project, upload your drawings for a fast DFM review and quote from our foundry engineers.