In the fields of industrial manufacturing and metalworking, “non-ferrous metal” is a frequently used but often misunderstood term. Simply put, non-ferrous metals are metals and alloys that are not primarily iron-based (i.e., they contain little to no iron as the main element). While their natural abundance and consumption are generally lower than those of ferrous metals, non-ferrous alloys have become indispensable in modern casting due to their unique physical and chemical properties.

This article provides a popular science overview of the basic definition, classification, and unique characteristics of non-ferrous metals in casting applications.

What Is a Non-Ferrous Metal?

The scientific definition of a non-ferrous metal is straightforward: any metal or alloy that does not have iron as its primary constituent. Although these materials may contain trace amounts of iron as impurities, their core chemical characteristics are not determined by iron.

A fundamental science point regarding non-ferrous metals is their relationship with rust. Non-ferrous metals do not form red iron-oxide rust, because rusting is a chemical reaction specific to iron. While they can still oxidize or corrode in certain environments, many non-ferrous metals—such as aluminum and zinc—often form a dense oxide film that can slow further attack under suitable conditions.

Furthermore, the scope of non-ferrous metals is vast. It includes everything from everyday aluminum cans and copper wiring to precious metals like gold, and high-performance titanium alloys used in aerospace components.

A Brief History of Non-Ferrous Metals

The history of non-ferrous metals is essentially the history of human civilization. For thousands of years before the mastery of iron smelting, non-ferrous metals were the primary drivers of progress and innovation.

- The Chalcolithic and Bronze Ages: Copper was among the first metals used by humans, with evidence of natural copper usage dating back to approximately 5000 BC. By alloying copper with tin to create bronze, humans produced significantly harder tools and weapons. This transition officially marked the start of the Bronze Age, drastically enhancing both productivity and military capabilities.

- Ancient Precious Metals: Gold and silver have been the preferred materials for currency, jewelry, and art since antiquity due to their chemical stability and lustrous appeal. They served as the central medium for ancient trade and cross-cultural exchange for millennia.

- The Rise of the Aluminum Industry: Although aluminum is the most abundant metal in the Earth’s crust, it is highly reactive and was extremely difficult to extract. It wasn’t until the late 19th century, with the invention of the Hall-Héroult electrolytic process, that aluminum could be produced on an industrial scale. Its lightweight properties quickly revolutionized the aviation, aerospace, and modern transportation sectors.

- Discovery of Strategic Metals: Entering the 20th century, breakthroughs in metallurgical technology led to the isolation and application of titanium, magnesium, and various rare metals. Due to their high heat resistance, extreme strength, or ultra-low density, these metals have become indispensable strategic resources for cutting-edge fields such as nuclear energy, semiconductors, and deep-sea exploration.

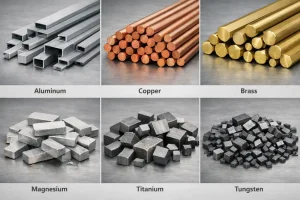

Common Examples of Non-Ferrous Metals

For easier understanding, we can categorize the non-ferrous metals commonly used in industry into several major systems. These metals exhibit distinct characteristics during the casting process:

- Aluminum (Al): Aluminum is among the most abundant metals in the Earth’s crust. It is lightweight, corrosion-resistant, and has excellent thermal conductivity, making it the most widely used non-ferrous metal in the foundry industry.

- Copper (Cu): One of the first metals used by humans. Its superior electrical conductivity makes it the cornerstone of the power industry. In casting, it often appears as Brass (copper-zinc) or Bronze (copper-tin).

- Zinc (Zn): Known for its low melting point and excellent fluidity. This allows it to perform exceptionally well in precision die casting, producing parts with extremely thin walls.

- Magnesium (Mg): As the lightest structural metal, magnesium’s density is about two-thirds that of aluminum. It is a key material for weight reduction in aerospace and high-performance racing.

- Titanium (Ti): Possesses extreme strength and heat resistance while being much lighter than steel. It is a cutting-edge material for high-end industries, often used in medical implants and specialized aerospace parts.

Core Characteristics of Non-Ferrous Metals

Non-ferrous metals are widely used because they offer specific physical properties that are often difficult to achieve with standard steel or iron:

Corrosion Resistance

Most non-ferrous metals offer a natural advantage in humid or chemically active environments. Aluminum, for instance, generates a thin film of aluminum oxide upon contact with air, providing a level of self-protection that is highly favored in construction and marine engineering.

Electrical and Thermal Conductivity

While steel is often the structural skeleton of a project, non-ferrous metals act as the “nerves” and heat sinks. Copper and aluminum are currently the most efficient and cost-effective materials for energy and heat transmission.

Magnetism

The vast majority of non-ferrous metals are non-magnetic. This property is crucial in the electronics industry and for medical equipment (such as components for MRI machines) to avoid electromagnetic interference.

Density

Compared to heavy steel, low-density metals like aluminum and magnesium significantly reduce the dead weight of vehicles and machinery, which directly translates to reduced energy consumption and lower carbon emissions.

Applications of Non-Ferrous Metals in Casting

In non-ferrous casting, matching the alloy to the specific application is essential. Every metal system serves a unique role based on its weight, durability, and environmental resistance.

Aluminum Alloys

Aluminum casting is a common choice for parts where weight reduction, corrosion resistance, and heat dissipation are priorities.

- Automotive Industry: Engine blocks, gearbox housings, and wheels.

- Electronics: Laptop shells, phone internal frames, and audio heat sinks.

- Architectural: Outdoor lighting housings and window frame components.

Copper Alloys

Copper alloys like brass and bronze are used where durability, wear resistance, and aesthetics are required.

- Fluid Control: Faucets, valve components, and water meter housings.

- Marine Engineering: Ship propellers, pump impellers, and underwater connectors.

- Mechanical: Bearing bushings, gears, and worm wheels.

Magnesium Alloys

Magnesium is used in high-end manufacturing sectors where extreme weight sensitivity is the primary concern.

- Aerospace: Aircraft seat frames and satellite brackets.

- Handheld Tools: Power housings for chainsaws and electric drills.

- Sporting Goods: Racing car steering wheel frames and professional camera bodies.

Zinc Alloys

Zinc alloys are known for their excellent fluidity, allowing for complex, high-precision details.

- Hardware: High-end belt buckles, keychains, and trophies.

- Connectors: Interface shielding for electronics and car lock cylinders.

Non-Ferrous vs. Ferrous Metals: Quick Comparison

| Feature | Non-Ferrous Metals | Ferrous Metals |

| Core Composition | Not primarily iron-based | Primarily iron-based (Fe) |

| “Rust” | No red iron-oxide rust | Can form iron-oxide rust (unless protected) |

| Magnetism | Usually non-magnetic | Often magnetic (varies by alloy) |

| Weight | Often lighter (e.g., Al, Mg) | Often heavier |

| Conductivity | Often higher | Often lower |

Conclusion

With their diverse physical properties and excellent processing performance, non-ferrous metals offer infinite possibilities for modern industry. From everyday items to cutting-edge technology, selecting the right material directly determines product durability and efficiency.

If you’re selecting a metal for a cast part, matching the alloy system to the service environment and process is key. Upload your drawings for a fast DFM review and quote today.