Metal strength is the ability of a material to withstand external forces without deforming or breaking. From the steel beams supporting a building to high-speed rotating mechanical parts, variations in strength determine the load-bearing limits and application boundaries of a material.

In engineering practice, strength is not a single value but a collection of properties including tensile, yield, and toughness. Understanding these dimensions is essential for determining whether a metal can operate reliably under specific working conditions.

This guide systematically reviews these mechanical indicators and compares the performance of common industrial metals to help you establish a logical approach to material selection in the early stages of your project.

Key Indicators of Metal Strength

When evaluating metal performance, strength must be defined based on how the load is applied. These specific dimensions of performance not only dictate the physical limits of a material but also directly influence the accuracy of engineering material selection. Common categories of strength include:

Tensile Strength

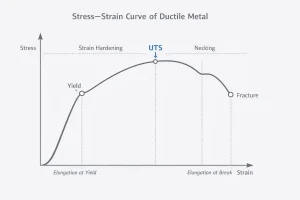

Tensile Strength refers to the maximum stress a metal can withstand while being stretched or pulled before breaking. Mechanically, the load is characterized by opposing forces pulling outward from the top and bottom (or left and right), acting to elongate the material toward its poles. It is a core indicator for evaluating the reliability of components like suspension bridge cables and crane hoists.

In professional material evaluation, tensile performance encompasses three distinct indicators, measured by applying an axial pull using a Universal Testing Machine (UTM):

- Proportional Limit: Defines the upper limit of purely elastic behavior. It is the core metric for ensuring absolute dimensional stability in high-precision engineering.

- Yield Strength: Defines the material’s resistance to permanent plastic deformation. As the most common safety benchmark, it determines the maximum load a part can handle without irreversible distortion.

- Ultimate Tensile Strength (UTS): Defines the absolute peak stress a material can withstand. It represents the ultimate safety reserve and is the deciding factor in preventing catastrophic structural failure under extreme conditions.

Compressive Strength

Compressive Strength measures a metal’s ability to resist deformation or failure under a compressive load. Mechanically, this load is characterized by opposing squeezing forces applied from the top and bottom (or left and right). These forces push the material toward its center, acting to shorten its axial length and compact its internal structure.

Testing is typically conducted using a Universal Testing Machine (UTM). A standard cylindrical specimen is placed on the base, and the machine’s crosshead moves downward from the top, creating an inward squeezing force against the stationary base. As the pressure increases, ductile metals will bulge outward laterally, while brittle metals will eventually shatter. The machine records the peak load reached before failure to calculate the final compressive strength.

Impact Strength

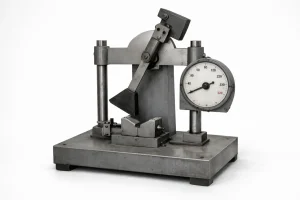

Impact Strength describes a metal’s ability to absorb energy and resist fracturing during a sudden, high-energy blow. The load is characterized by a momentary, explosive force from the front or side. It determines whether a material will bend or shatter during a collision, making it vital for armor plating and automotive crash beams.

Unlike static pressure, this is a high-speed kinetic energy release. High-toughness materials dissipate this energy through plastic deformation to prevent crack propagation. Testing is typically conducted via a Pendulum Impact Test (Charpy), where a weighted pendulum swings laterally to strike a notched specimen. The energy absorbed is calculated based on the pendulum’s height difference after the impact.

Ductile materials with high impact strength exhibit visible bending or tearing before failure, whereas brittle materials absorb minimal energy and shatter instantaneously upon impact. This behavior is a critical factor in evaluating structural safety under dynamic loading conditions.

Metal Strength Chart

In engineering material selection, metal strength is typically evaluated using indicators such as yield strength, tensile strength, density, and hardness. The table below summarizes typical parameters for several common engineering metals and can be used to compare their relative strength levels.

| Metal / Alloy Type | Representative Grade | Yield Strength (MPa) | Tensile Strength (MPa) | Mohs Hardness | Density (g/cm³) |

| Low-Alloy Steel Casting | 42CrMo | 650 – 900 | 900 – 1100 | 6.0 – 7.0 | 7.85 |

| Ductile Iron | QT450-10 | 310 – 350 | 450 – 500 | 4.5 – 5.5 | 7.10 |

| Carbon Steel Casting | WCB / ZG270-500 | 270 – 300 | 500 – 650 | 5.0 – 6.0 | 7.85 |

| Aluminum Casting Alloy | A356-T6 / ADC12 | 150 – 280 | 230 – 320 | 2.5 – 3.0 | 2.70 |

| Stainless Steel Casting | CF8 / CF8M | 205 – 240 | 485 – 550 | 5.0 – 6.0 | 7.90 |

| Brass / Bronze Casting | CuZn37 / Bronze | 180 – 400 | 300 – 550 | 3.0 – 4.0 | 8.45 |

| Gray Cast Iron | HT250 | 150 – 250 | 250 – 400 | 4.0 – 6.0 | 7.10 |

Why is Metal Strength Important?

Choosing the right metal strength involves a deep trade-off between safety, economy, and functionality.

In terms of Safety, metal strength is the baseline insurance for modern civilization. Whether it is a dam gate holding back millions of tons of water or a jet wing flying at high speeds, materials must possess a strength reserve that exceeds the maximum expected load. Inaccurate assessments can lead to metal fatigue or structural failure, resulting in catastrophic consequences.

Regarding Industrial Efficiency, strength directly affects lightweighting and energy performance. In the automotive and aerospace sectors, higher-strength materials allow engineers to reduce the cross-sectional area of parts, thereby lowering the overall weight of the vehicle or aircraft. This reduction significantly cuts fuel consumption and increases payload capacity.

Furthermore, metal strength defines the limits of Extreme Exploration. Only metals with top-tier compressive and creep strength can survive the immense pressures of the deep sea or the intense heat inside a jet engine. Every breakthrough in high-strength materials effectively expands the physical frontiers of human engineering.

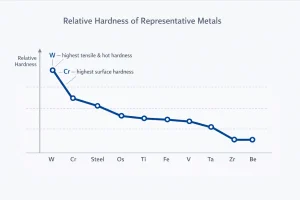

Top 10 Strongest Metals

Based on a comprehensive evaluation of Mohs hardness, yield strength, and tensile strength, here are the top ten performers in the metallic world:

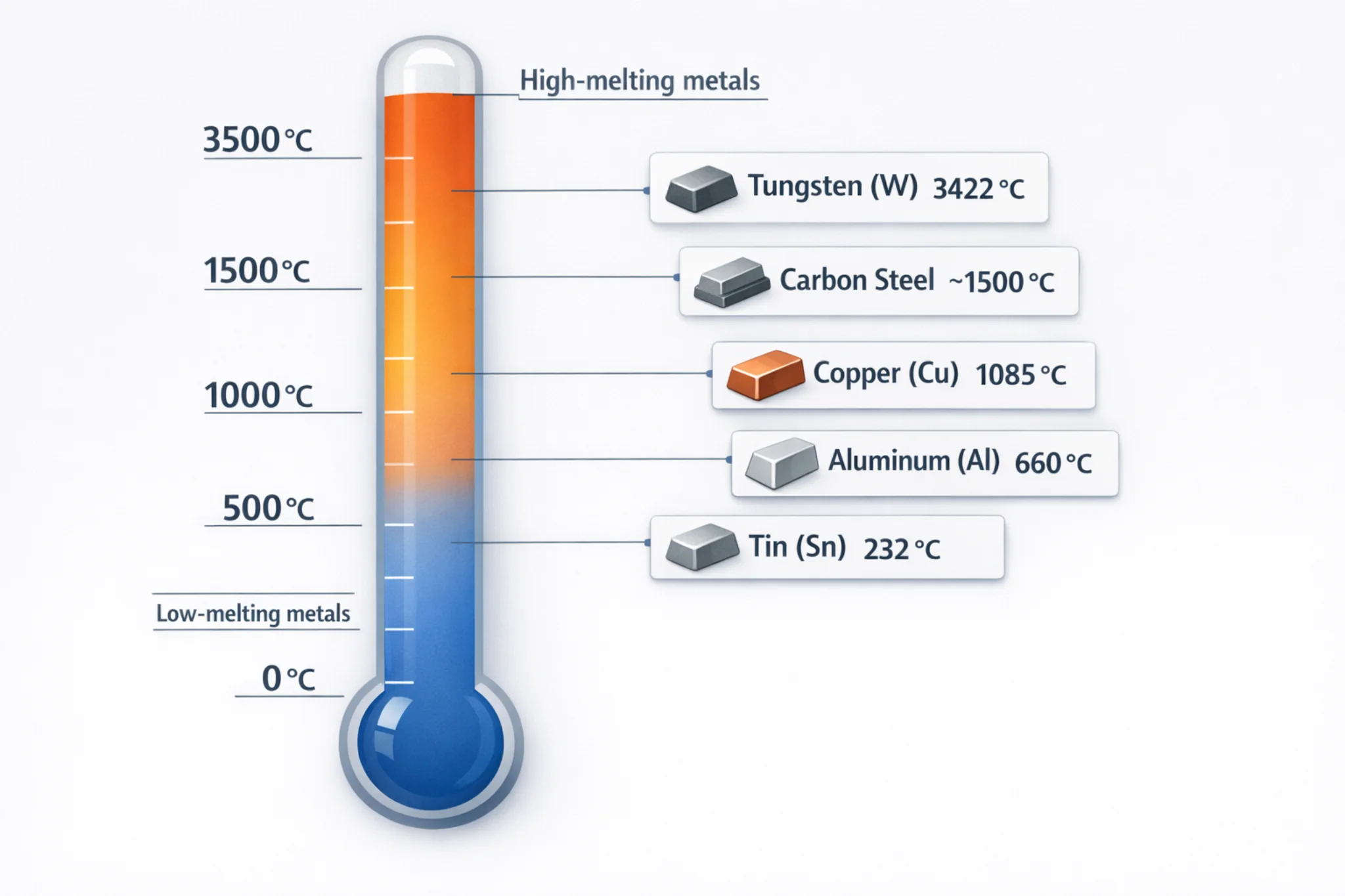

Tungsten

Tungsten has the highest tensile strength of any natural metal and the highest melting point. Its incredible hardness and heat resistance make it the primary choice for armor-piercing rounds and aerospace components.

Chromium

Chromium is the hardest elemental metal on the Mohs scale. While relatively brittle, its superior surface hardness and corrosion resistance make it the essential ingredient for stainless steel and wear-resistant coatings.

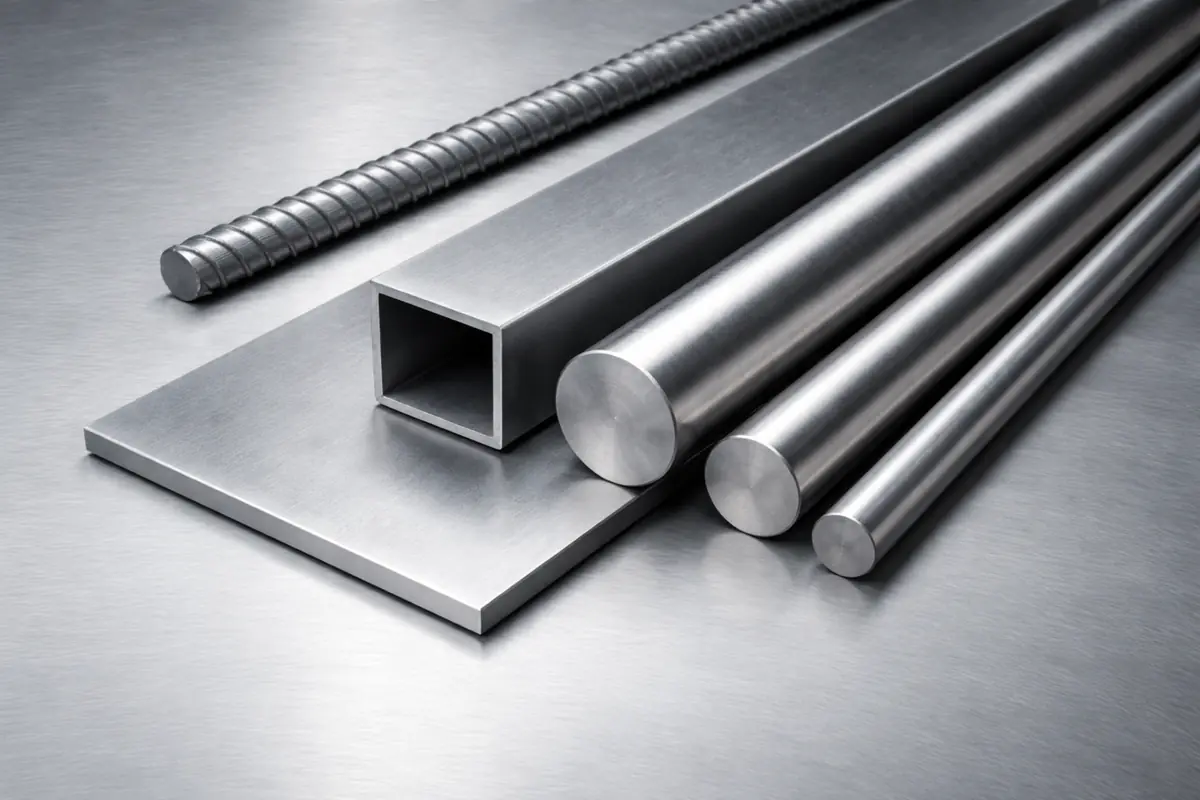

Steel

As an alloy, steel’s dominance in modern industry is unparalleled. By adjusting carbon content and heat treatment, steel achieves a superior balance of strength and toughness, serving as the backbone of construction and machinery.

Osmium

One of the densest elements in nature, Osmium has an extremely high bulk modulus. Although very hard, it is brittle and typically used in precision instrument bearings where extreme wear resistance is required.

Titanium

Titanium is renowned for its exceptional strength-to-weight ratio. It is as strong as high-quality steel but nearly 50% lighter, making it ideal for fighter jets, submarines, and medical implants.

Iron

While pure iron is moderately strong, its abundance and alloying potential make it the most important metal in human history. When alloyed, it can exhibit extraordinary mechanical properties.

Vanadium

Often called the “vitamin” of the industry, adding small amounts of vanadium significantly increases the strength and fatigue resistance of steel, used extensively in automotive chassis and high-speed tools.

Tantalum

Tantalum possesses a high melting point and excellent chemical stability. It maintains its mechanical strength even in extremely corrosive environments or at high temperatures, critical for chemical reactors.

Zirconium

Zirconium holds a unique position in the nuclear industry. It combines excellent mechanical strength with a low neutron-absorption cross-section, making it the preferred material for nuclear fuel cladding.

Beryllium

Beryllium is an extremely lightweight but highly rigid metal. Its thermal stability is exceptional, and it is used for structural supports in precision optics, such as the mirrors of the James Webb Space Telescope.

Conclusion

In the manufacturing sector, the application of metal strength is a science of balancing physical limits with production feasibility. For buyers and engineers, selecting the right metal requires more than just looking at theoretical data; it involves considering casting methods, material costs, and the specific working environment of the final product. The ideal material solution is almost always an optimal balance between tensile strength, compression, hardness, and toughness—ensuring long-term supply chain stability and structural integrity.

If you are looking for the best metal casting solution for a specific industrial project, or need a custom high-strength alloy for extreme pressure environments, contact our technical team today for professional material analysis and production support.