What is melting point? In physics and engineering, the melting point is the critical temperature at which a metal transitions from a solid state to a liquid state. At this temperature, the molecular structure of the metal changes, providing the fluidity required to flow into molds. Accurate melting point data is not only the foundation of the smelting process but also essential for controlling energy consumption, protecting tool life, and preventing casting defects.

Common Industrial Metal Melting Points

The following table provides core melting point data for the most frequently used industrial metals for quick reference:

| Metal Name | Melting Point (°C) | Melting Point (°F) | Melting Point (Kelvin) |

| Zinc | 419.5 | 787.1 | 692.7 |

| Aluminum | 660.3 | 1220.5 | 933.5 |

| Brass | 905 – 932 | 1660 – 1710 | 1178 – 1205 |

| Pure Copper | 1084.6 | 1984.3 | 1357.8 |

| Gray Iron | 1150 – 1260 | 2102 – 2300 | 1423 – 1533 |

| Carbon Steel | 1425 – 1540 | 2597 – 2804 | 1698 – 1813 |

Comprehensive Metal and Alloy Melting Point Reference

This detailed list covers a full spectrum from low-melting-point fusible metals to high-melting-point specialty materials:

| Metal / Alloy | Melting Point (°C) | Melting Point (°F) | Melting Point (Kelvin) |

| Tin | 231.9 | 449.4 | 505.1 |

| Lead | 327.5 | 621.5 | 600.7 |

| Zinc | 419.5 | 787.1 | 692.7 |

| Zinc Alloy | 381 – 387 | 718 – 729 | 654 – 660 |

| Magnesium | 650.0 | 1202.0 | 923.2 |

| Magnesium Alloy | 470 – 595 | 878 – 1103 | 743 – 868 |

| Aluminum | 660.3 | 1220.5 | 933.5 |

| Aluminum Alloy | 557 – 613 | 1035 – 1135 | 830 – 886 |

| Brass | 900 – 940 | 1652 – 1724 | 1173 – 1213 |

| Bronze | 913 – 1040 | 1675 – 1904 | 1186 – 1313 |

| Pure Copper | 1084.6 | 1984.3 | 1357.8 |

| Gray Iron | 1150 – 1260 | 2102 – 2300 | 1423 – 1533 |

| Ductile Iron | 1150 – 1200 | 2102 – 2192 | 1423 – 1473 |

| Pure Nickel | 1455.0 | 2651.0 | 1728.2 |

| Carbon Steel | 1425 – 1540 | 2597 – 2804 | 1698 – 1813 |

| Stainless Steel | 1370 – 1450 | 2498 – 2642 | 1643 – 1723 |

| Titanium | 1668.0 | 3034.4 | 1941.2 |

| Tungsten | 3422.0 | 6191.6 | 3695.2 |

Conversion Formulas:

Celsius to Fahrenheit: °F = (°C × 9/5) + 32

Celsius to Kelvin: K = °C + 273.15

Frequently Asked Questions (FAQ)

Based on common queries from engineers and procurement professionals, we have summarized the following technical answers:

Which metal has the highest melting point?

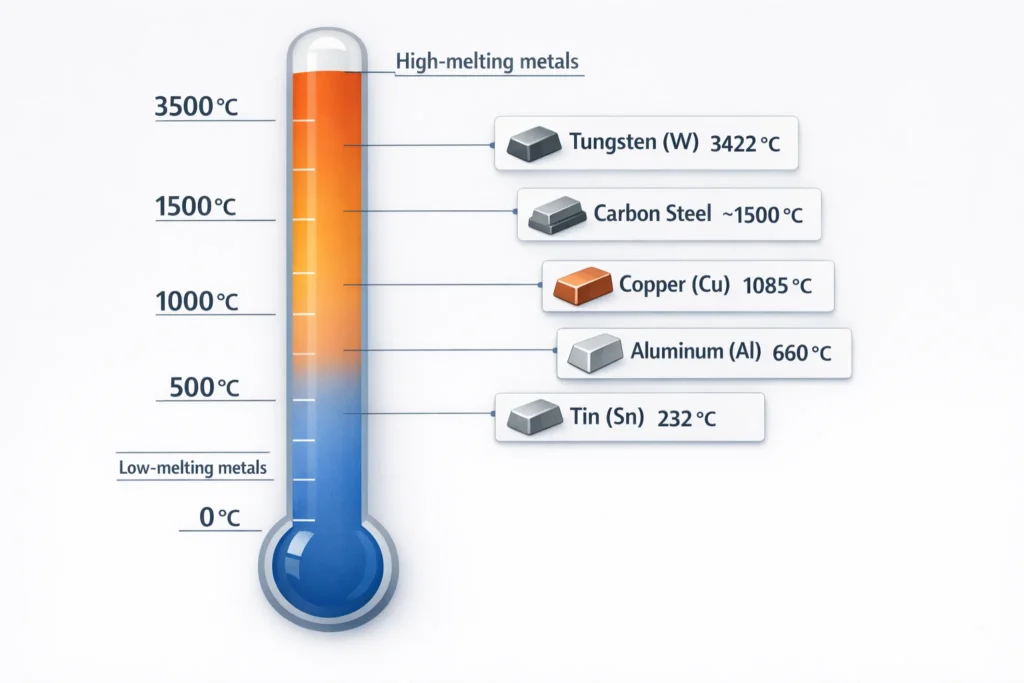

Among all naturally occurring metallic elements, Tungsten (W) possesses the highest melting point at 3422°C (6192°F). This exceptional heat resistance makes it indispensable in extreme environments, serving as a core component for aerospace engine nozzles, vacuum furnace heating elements, and high-strength alloys.

Which metal is the easiest to melt?

If selecting from metals that are solid at room temperature, Tin (Sn) is the easiest to melt, requiring only 231.9°C to turn liquid. However, in the entire metal family, Mercury (Hg) has the lowest melting point at -38.8°C, meaning it exists as a liquid at room temperature without any heating.

Are there any metals that cannot be melted?

Theoretically, all metals can be melted if enough energy is provided under appropriate pressure. However, in industrial practice, some metals (such as Chromium) are highly reactive and may undergo severe oxidation or sublimation before reaching their melting point. Consequently, these materials are considered “difficult to melt directly” and must be processed in specialized environments like vacuum or inert gas protection.

Application of Data Fields in Industrial Decision Making

- Celsius (°C): The primary setting unit for industrial furnace PID temperature control systems. In production, the pouring temperature is typically set 50°C to 150°C above the melting point (liquidus) to ensure sufficient fluidity.

- Fahrenheit (°F): Mainly used when dealing with North American technical specifications, imported equipment manuals (e.g., Inductotherm systems), and related ASTM international heat treatment standards.

- Kelvin (K): Widely used in CAE mold flow analysis software (like Magma or AnyCasting). Kelvin is the essential thermodynamic input for predicting shrinkage porosity risks during the solidification phase of parts.

Data Sources & References

- Pure Metals: Physical constants are sourced from the National Institute of Standards and Technology (NIST) Chemistry WebBook, SRD 69.

- Industrial Alloys: Melting ranges (Solidus/Liquidus) are cross-referenced from ASM Handbook, Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials.

- Commercial Standards: Supplemental engineering data provided by MatWeb Material Property Data.