In the pursuit of high energy efficiency and agile manufacturing, the selection of materials directly determines a product’s market competitiveness. Light metals have become core materials in aerospace, automotive engineering, and medical devices due to their exceptional specific strength.

As manufacturing technologies evolve, achieving maximum lightweighting without compromising structural integrity has become a primary objective in engineering design. This article explores the definition, advantages, and application logic of light metals in various industrial contexts.

What are Light Metals?

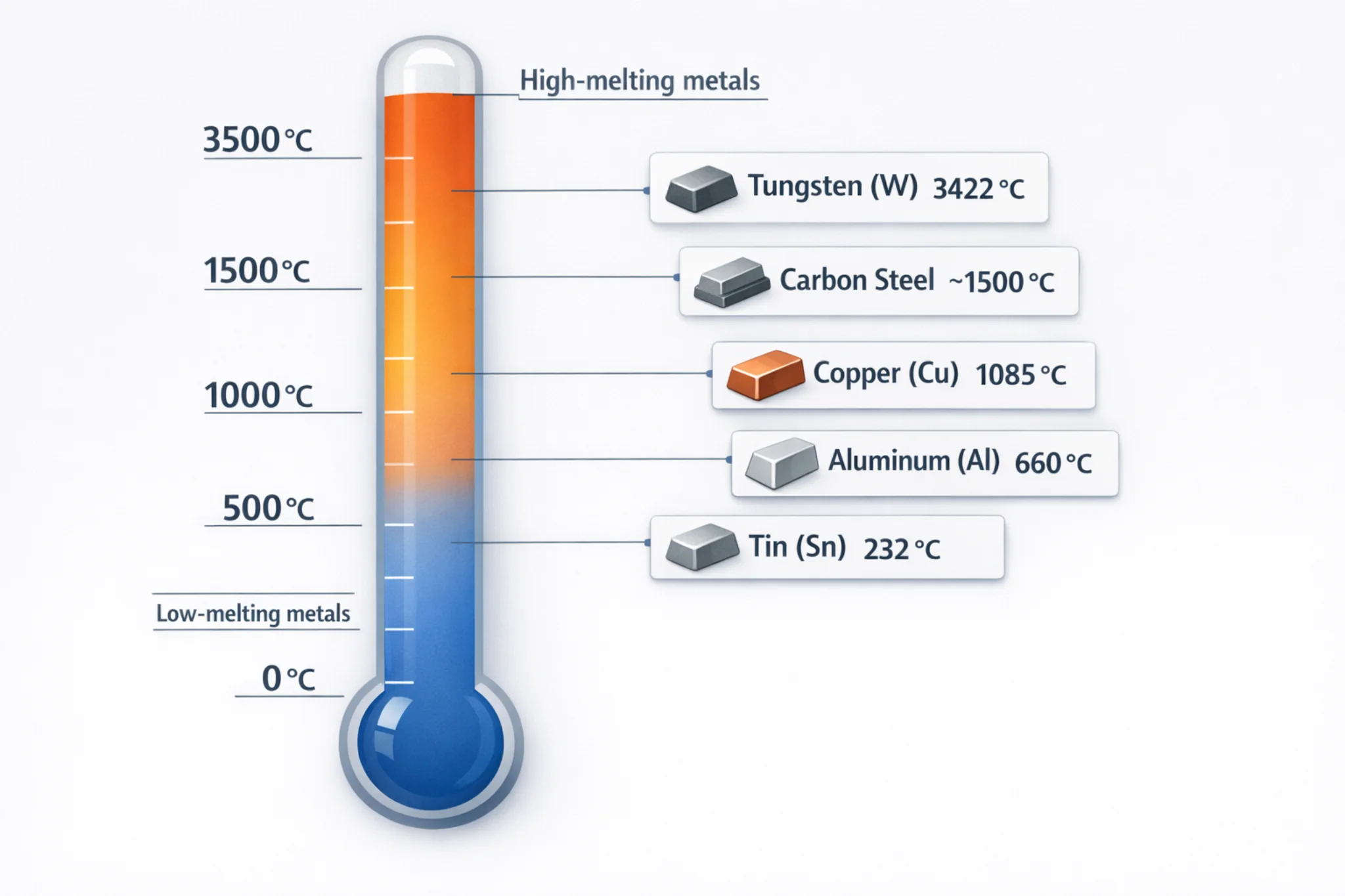

From a metallurgical perspective, light metals are generally defined as metallic elements with a density of less than 5 g/cm³. The core members of this group include aluminum, magnesium, and titanium, which are abundant in nature and possess excellent machining adaptability.

In production practice, light metals rarely exist in their pure elemental form. Instead, they are enhanced through alloying with elements such as manganese, zinc, or silicon to improve physical properties. This alloying process allows light metals to maintain low density while achieving mechanical performance that rivals or exceeds traditional steel, providing broader design possibilities for modern precision manufacturing.

Advantages of Light Metals

The dominance of light metals in modern industry is primarily attributed to the balance they strike between physical performance and economic efficiency:

- Exceptional Strength-to-Weight Ratio: Capable of supporting high mechanical loads while significantly reducing dead weight.

- Superior Thermal and Electrical Conductivity: Making aluminum and magnesium alloys ideal for heat sinks and electronic packaging.

- Excellent Corrosion Resistance: Titanium and specific aluminum alloys exhibit high chemical stability in harsh environments.

- High Recyclability: Unlike composite materials, light metals are easily recycled, aligning with sustainable manufacturing trends.

- High Machining Efficiency: In CNC machining, light metals often allow for higher cutting speeds than hardened steels, effectively reducing production time.

Types of Light Metals

To harness the potential of these materials, it is essential to understand the physical characteristics and typical use cases of the industry’s most common light metals.

1. Aluminum Alloys

Aluminum alloys are the most widely used light metals in industry, with a density of approximately 2.7g/cm³. These materials are characterized by excellent thermal and electrical conductivity, along with superior machinability, and can meet a wide range of strength requirements through different alloying processes.

In engineering applications, the 6000 series is commonly used for general structural components, while the 7000 series is frequently employed in aerospace parts that demand high fatigue strength. Their mature surface treatment processes and high cost-effectiveness make them a dominant choice in both industrial manufacturing and consumer electronics.

2. Magnesium Alloys

Magnesium alloys are the lowest-density structural metals currently used in engineering, with a density of about 1.8g/cm³, which is roughly two-thirds that of aluminum. Key physical properties include an excellent specific strength, superior vibration damping, and strong electromagnetic shielding capabilities.

These materials excel in fields with extreme weight reduction requirements, such as drone frames, high-performance racing components, and portable device housings. While machining requires specific fire prevention measures, their low cutting resistance and high shock absorption provide significant advantages in precision manufacturing.

3. Titanium Alloys

Titanium alloys have a density of approximately 4.5g/cm³, with performance indicators positioned between those of aluminum and steel. Their core advantages lie in an exceptionally high specific strength and superior corrosion resistance, maintaining mechanical stability even in high-temperature environments reaching 500°C.

Due to their reliability under extreme conditions, titanium alloys are widely utilized in aircraft engine blades, deep-sea pressure hulls, and medical implants. Despite higher machining difficulty and material costs, their comprehensive performance makes them an irreplaceable solution in advanced manufacturing sectors.

4. Beryllium Alloys

Beryllium alloys are specialized light metals known for extreme rigidity, with a density of approximately 1.85g/cm³. The most significant technical feature is an elastic modulus about 1.5 times that of steel, which provides the material with exceptional dimensional stability and minimal deformation in complex environments.

These alloys are primarily used in space-grade precision instruments, such as mirror substrates for satellite optical systems and inertial navigation components. Due to strict environmental protection requirements during processing, their application is generally concentrated in high-standard defense and cutting-edge research scenarios.

5. Aluminum-Lithium Alloys

Aluminum-lithium alloys are advanced materials specifically engineered to meet the stringent efficiency requirements of modern aerospace design. By incorporating lithium into the aluminum matrix, these alloys achieve a significant reduction in density while simultaneously increasing the elastic modulus.

Currently, they are integrated into the primary structural frameworks of advanced civil aviation platforms. Their superior fatigue resistance and substantial weight-saving potential represent the cutting edge of aluminum technology, enabling the development of more sustainable and high-performance aerospace vehicles.

Metal Classification: Non-Ferrous, Light, and Heavy

To select the right material, it is essential to understand where light metals fit within the broader metallurgical landscape. The primary distinction lies in composition and density:

- Non-Ferrous Metals: This is the broad “parent” category. It includes all metals and alloys that do not contain iron as their main component (excluding Iron, Manganese, and Chromium). It is a classification based on chemical composition.

- Light Metals: A specific sub-group of non-ferrous metals defined by low density, generally below 5.0 g/cm³. Common examples include Aluminum, Magnesium, and Titanium. They are the primary choice for weight-reduction applications.

- Heavy Metals: Non-ferrous metals with a density above 5.0 g/cm³. Common examples include Copper, Lead, and Zinc. While they are “heavy,” they offer unique advantages in electrical conductivity or specific chemical properties.

Summary Logic: All light metals are non-ferrous, but not all non-ferrous metals are light. Choosing a “Light Metal” is a specific engineering decision to prioritize low density within the non-ferrous family.

Comparison of Light Metals

By comparing these metals across key dimensions, engineers can better visualize their performance differences under varying requirements.

| Parameters | Aluminum | Magnesium | Titanium | Beryllium | Al-Li |

| Symbol | Al | Mg | Ti | Be | Al-Li |

| Density (g/cm³) | ~2.7 | ~1.8 | ~4.5 | ~1.85 | ~2.5-2.6 |

| Specific Strength | High | Very High | Exceptional | Very High | Very High |

| Machinability | Excellent | Good (Fire risk) | Challenging | Extreme (Toxicity) | Good |

| Corrosion Resistance | Good | Fair | Excellent | Good | Good |

| Material Cost | Low | Moderate | High | Very High | High |

Data provided are typical values for general reference only. Specific properties may vary based on heat treatment and alloying elements.

Density and Weight

As shown in the data, magnesium and beryllium represent the performance ceiling for weight-sensitive structural applications. Aluminum maintains the most versatile balance between density and cost, while aluminum-lithium alloys provide a strategic 10–15% weight advantage over standard grades in modern aerospace structures.

Although titanium is the densest among light metals, its exceptional specific strength remains the industry gold standard for high-stress environments. This allows engineers to achieve superior structural integrity with minimal material volume, effectively offsetting the higher base density of the metal.

Machining and Technology

Aluminum and aluminum-lithium alloys offer the highest machining efficiency, characterized by rapid material removal rates and low tooling costs. Magnesium also exhibits excellent cutting properties, though it necessitates specialized safety protocols and fire suppression systems to manage the flammability of fine metallic chips.

In contrast, titanium and beryllium present significant manufacturing hurdles. Titanium requires specialized CNC strategies and high-pressure cooling due to its low thermal conductivity and high cutting forces. Beryllium is the most constrained option, requiring hermetically sealed environments and strict regulatory compliance to mitigate the extreme toxicity risks associated with its dust.

How to Choose the Right Light Metal

Choosing the right material is a process of balancing different requirements. Instead of looking for a single “best” metal, you should evaluate these key dimensions to make a pre-selection for your project:

- Maintenance and Appearance: Think about long-term rust protection and aesthetics. Aluminum is excellent for anodizing and can be finished in many colors. If you choose magnesium, you must account for the extra steps and costs of special protective coatings to prevent corrosion.

- Mechanical Performance: Evaluate materials based on the specific strength and durability required. If your design must handle extreme stress without failing, titanium is the gold standard. For lighter, everyday structural needs where extreme strength isn’t the priority, aluminum or magnesium is usually sufficient.

- Operating Temperature: Consider how hot the environment will get. Aluminum starts to “soften” and lose its structural integrity once temperatures exceed 200°C. If your product operates near engines or in other high-heat zones, the heat resistance of titanium becomes a necessity.

- Cost and Budget: Determine if the weight savings justify the price gap. Aluminum is the most budget-friendly option for mass production. However, in professional racing or aerospace, where saving every gram provides a massive performance boost, the high cost of magnesium or titanium is a logical investment.

- Manufacturing and Processing: Factor in the difficulty of making the part. Aluminum is very easy to machine, which keeps production costs low. If you choose titanium or beryllium, you must be prepared for much higher labor costs and longer production cycles due to the specialized equipment required.

FAQ

The following technical facts address common questions regarding light metals to help designers clarify core concepts.

What are the 10 lightest metals?

Ranked from lowest to highest density, they are: Lithium (Li), Potassium (K), Sodium (Na), Rubidium (Rb), Calcium (Ca), Magnesium (Mg), Aluminum (Al), Beryllium (Be), Strontium (Sr), and Barium (Ba).

What is the absolute lightest metal?

Lithium (Li) is the lightest metal on the periodic table, with a density of 0.534 g/cm³—roughly half that of water. Due to its high reactivity, it is used primarily in battery technology rather than standalone structures.

What is the heaviest metal?

Osmium (Os) is the densest known metal, with a density of 22.59 g/cm³. It is often used in high-hardness alloys for precision instruments and wear-resistant bearings.

What is the lightest yet strongest metal?

In industrial applications, titanium alloys are considered to have the highest specific strength. While magnesium and aluminum are lighter, titanium leads in tensile strength relative to its weight.

What metals are lighter than titanium?

Among structural metals, both aluminum (Al) and magnesium (Mg) are lighter than titanium. Aluminum’s density is ~60% of titanium’s, while magnesium’s is only ~40%.

Is stainless steel a light metal?

No. Stainless steel is primarily composed of iron, with a density between 7.75 and 8.05 g/cm³, far exceeding the 5 g/cm³ threshold for light metals.

Conclusion

Light metals are the key to achieving agile manufacturing and energy savings. By understanding the unique characteristics of aluminum, magnesium, and titanium, engineers can find the optimal solution between performance, cost, and lead time.

If you are evaluating material options for a new project, feel free to consult our technical team. We provide full support from material selection to CNC process optimization.