Bronze and brass are two of the most common and historically significant copper alloys. While they share a similar golden appearance, their distinct compositions give them unique properties and applications. Understanding these differences is crucial for selecting the right material for any engineering or artistic project.

What Are Bronze and Brass?

Bronze is a copper-based alloy where the main alloying element is typically tin. It is known for its durability, hardness, and exceptional resistance to corrosion, particularly in saltwater environments.

Brass is a copper-based alloy where the main alloying element is zinc. The percentage of zinc can vary, which significantly affects its properties. Brass is recognized for its golden color, excellent machinability, and good acoustic properties.

Main Types of Bronze

Bronze can be categorized into various types based on its primary alloying element:

- Tin Bronze: The most traditional form of bronze, known for its good casting properties and high strength. It is commonly used for sculptures, bearings, and gears.

- Aluminum Bronze: Contains aluminum as the main alloy. It is highly resistant to corrosion and tarnishing, making it ideal for marine hardware, propellers, and pump components.

- Silicon Bronze: Contains silicon and is known for its high strength, ductility, and good weldability. It is often used for architectural and sculptural applications.

Main Types of Brass

Brass is also available in different types, depending on the percentage of zinc and other elements:

- Cartridge Brass (70/30 Brass): Contains 70% copper and 30% zinc. It is highly ductile and can be easily cold-worked, making it suitable for ammunition casings and musical instruments.

- Yellow Brass (65/35 Brass): A common and cost-effective brass with 65% copper and 35% zinc. It is widely used in decorative items and plumbing fixtures.

- Naval Brass: Contains a small amount of tin in addition to zinc, which significantly improves its corrosion resistance in marine environments. It is used for marine hardware and fasteners.

Core Performance Comparison

| Performance Metric | Bronze | Brass |

| Main Alloying Element | Tin | Zinc |

| Toughness & Hardness | Generally harder and more durable | Softer, more malleable |

| Corrosion Resistance | Excellent, especially in saltwater | Good, but susceptible to dezincification |

| Machinability | Good | Excellent (easier to machine) |

| Acoustic Properties | Good (e.g., bells, cymbals) | Excellent (e.g., trumpets, trombones) |

| Color | Reddish-brown, dull finish | Golden-yellow, bright finish |

Toughness and Hardness

This is a key differentiator. Bronze is generally harder and tougher than brass, which makes it more resistant to wear and fatigue. This is why it’s a preferred material for things like bearings and gears. Brass is softer and more malleable, making it easier to shape and form for applications where ductility is more important than strength.

Corrosion Resistance

Bronze exhibits superior resistance to corrosion, particularly in harsh environments like seawater, due to its tin content. This makes it an ideal choice for marine hardware and valves. While brass also has good corrosion resistance, it can be susceptible to dezincification, where zinc leaches out and leaves a porous, copper-rich structure.

Machinability

Brass is known for its excellent machinability. Its composition allows it to be easily cut, drilled, and milled with less tool wear, which makes it a preferred choice for intricate components. Bronze is also machinable, but it is generally harder and can be more difficult to work with compared to brass.

Acoustic Properties

Brass is highly valued for its acoustic properties, which is why it is the material of choice for most musical instruments like trumpets and trombones. Bronze also has good acoustic properties and is famously used for bells and cymbals, producing a rich, resonant tone.

Color

The most noticeable difference between the two is their color. Bronze has a distinct reddish-brown, often dull or oxidized finish. Brass has a bright, golden-yellow appearance that is often polished for decorative purposes.

Typical Application Scenarios

Due to their differences in properties, these two alloys are used in distinct fields.

Applications for Bronze

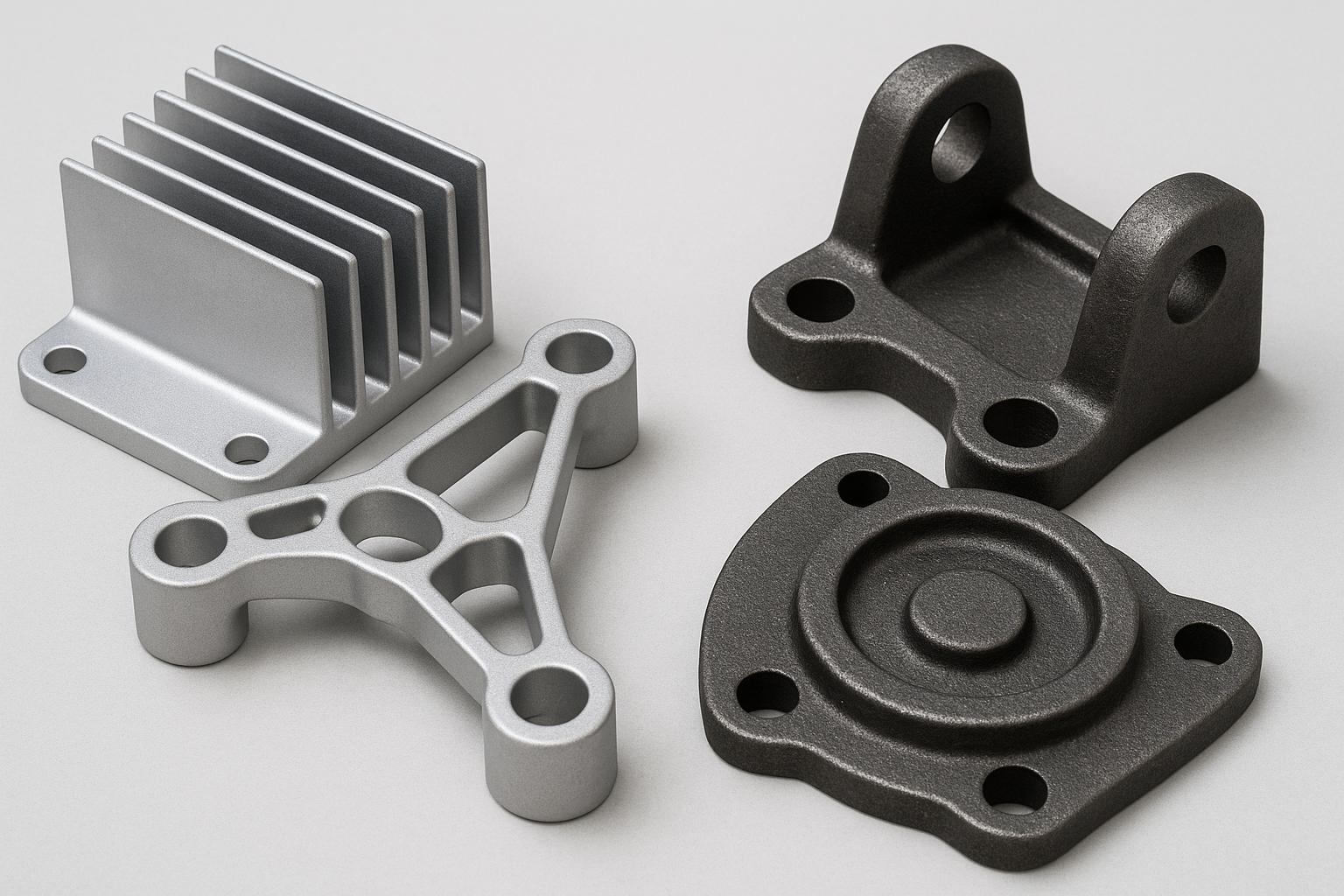

Bronze is primarily used where strength, durability, and corrosion resistance are critical. Its applications include:

- Sculptures and Art: Prized for its durability and casting properties.

- Marine Hardware: Propellers, fittings, and valves are often made of bronze due to its resistance to saltwater corrosion.

- Industrial Components: Bearings and gears benefit from its hardness and wear resistance.

- Musical Instruments: Bells and cymbals produce a rich, resonant tone.

Applications for Brass

Brass is commonly used in applications that benefit from its machinability, aesthetic appeal, and acoustic properties. Its applications include:

Ammunition Casings: Its ductility allows it to be easily formed for this purpose.

Musical Instruments: Widely used for brass instruments like trumpets and trombones.

Plumbing and Hardware: Faucets, valves, and fittings are popular due to its machinability and good corrosion resistance.

Decorative Items: Its golden color makes it a great choice for decorative hardware and jewelry.

Conclusion

Simply put, if your project requires superior strength and corrosion resistance, especially in harsh environments, bronze is the ideal choice. However, if your needs prioritize machinability, a specific golden color, or acoustic performance, brass is the better option. Making the right material choice is crucial for ensuring the success and longevity of your project.

Ready to make the right material choice for your project? Contact our expert team today for a free consultation and quote. We’re here to help you cast your vision into reality.