410 stainless steel is a heat-treatable martensitic stainless steel that sits between carbon steel and 304/316 in both performance and cost. This guide explains what 410/CA15 is, its key properties, how it compares with 304 and 316, and when it is the right choice for pumps, valves and turbine components.

What is 410 Stainless Steel?

410 Stainless Steel is a typical martensitic stainless steel, designated as 410 / UNS S41000 according to AISI standards. It contains approximately 11.5–13.5% chromium and can be heat-treated (quenched and tempered) to achieve high strength and hardness while maintaining moderate corrosion resistance.

In the casting industry, the wrought 410 stainless steel usually corresponds to the casting grade CA15 (ASTM A743 / A217 / A487). As a heat-treatable iron-chromium alloy, CA15 provides mechanical properties close to those of engineering alloy steels when tempered, making it a preferred material for pump and valve components, turbines, and mechanical transmission parts.

Chemical Composition of 410 Stainless Steel

Based on common standards and data sheets, the typical chemical composition of 410 stainless steel (including the casting equivalent CA15) is as follows:

| Element | Typical Content (wt.%) | Role & Impact |

| Cr (Chromium) | 11.5 – 13.5 | Provides basic corrosion and oxidation resistance |

| C (Carbon) | 0.05 – 0.15 | Determines quenching hardness and strength levels |

| Ni (Nickel) | ≤ 0.75 | Slightly improves toughness and corrosion resistance |

| Mn (Manganese) | ≤ 1.0 | Deoxidizer, improves hardenability and castability |

| Si (Silicon) | ≤ 1.0 | Deoxidizer, improves molten steel fluidity |

| P (Phosphorus) | ≤ 0.04 | Impurity element, strictly controlled |

| S (Sulfur) | ≤ 0.03 | High levels reduce toughness and corrosion resistance |

| Fe (Iron) | Balance | Base metal |

410 is a high-chromium, medium-carbon alloy with low nickel content. This composition is the primary reason why it is heat-treatable and cost-effective, but limited in extreme corrosion environments.

Characteristics of 410 Stainless Steel

Mechanical and Physical Properties

| Category | Property | Annealed State (Typical) | Hardened & Tempered (Typical) |

| Mechanical | Tensile Strength (UTS) | 480 – 550 MPa | 650 – 850 MPa |

| Yield Strength (YS) | 275 – 350 MPa | 450 – 600 MPa | |

| Hardness | 180 – 220 HBW | 35 – 45 HRC | |

| Elongation | 20 – 25 % | 12 – 18 % | |

| Physical | Density | 7.75 g/cm³ | 7.75 g/cm³ |

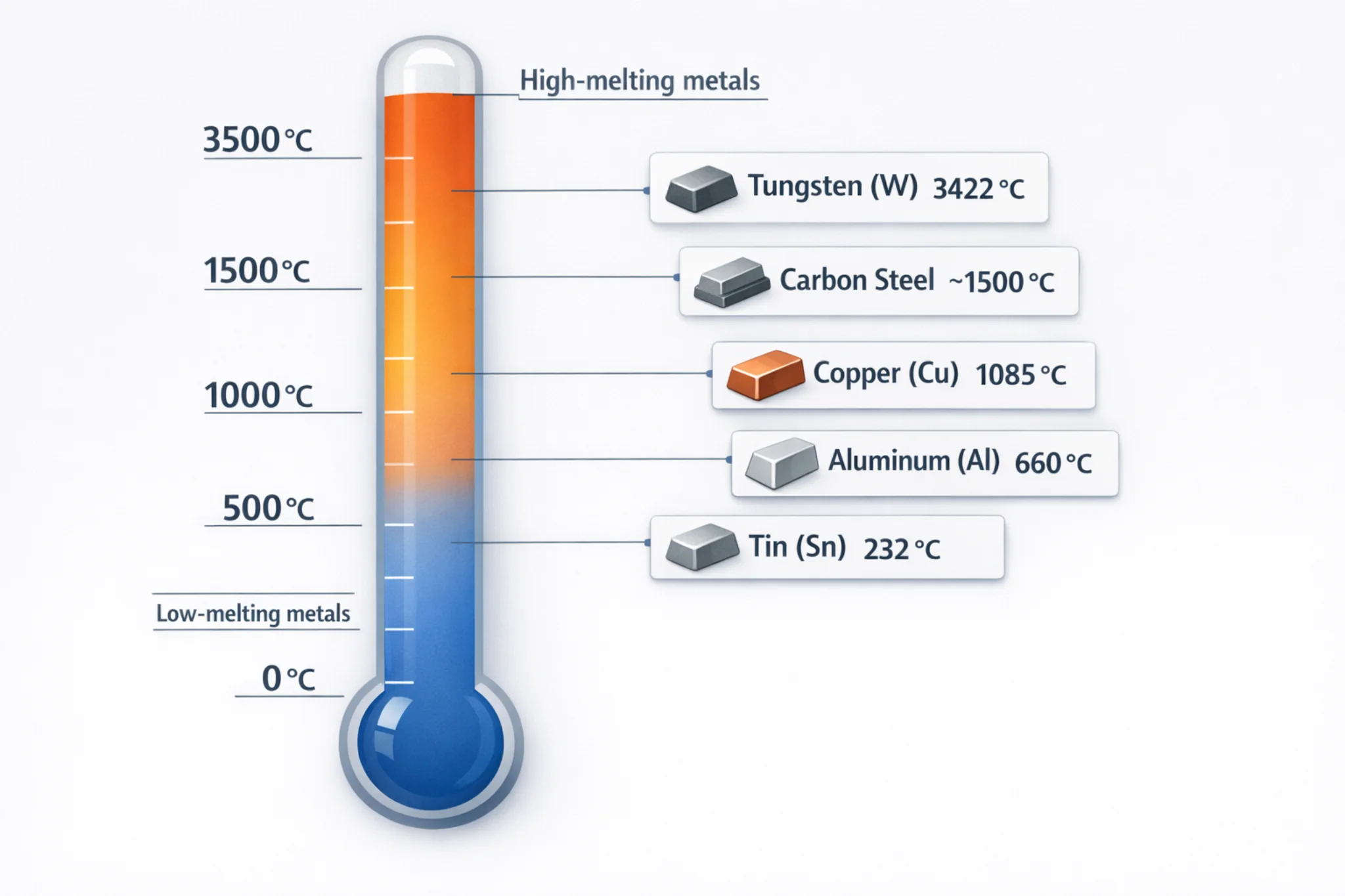

| Melting Point | 1425 – 1510 °C | 1425 – 1510 °C | |

| Thermal Conductivity (at 100°C) | 24.9 W/m·K | 24.9 W/m·K | |

| Coeff. of Thermal Expansion | 9.9 x 10⁻⁶ /K | 9.9 x 10⁻⁶ /K |

Corrosion Resistance

410 exhibits good resistance in atmospheric conditions, fresh water, oil, and most mild industrial media, significantly outperforming carbon steel. However, compared to austenitic grades like 304 and 316, its resistance is moderate. It is susceptible to pitting and crevice corrosion in high-chloride, strong acid, or marine environments.

Heat Treatment Capability

One of its strongest features is the ability to achieve a wide range of strength and hardness through “Annealing → Quenching → Tempering.” Its final performance is highly dependent on the tempering temperature, making it versatile for various engineering requirements.

Welding and Machinability

410 has moderate weldability but is sensitive to cracking due to its air-hardening nature. Preheating to 200-300°C is usually required, followed by Post-Weld Heat Treatment (PWHT) to eliminate brittle martensite. In terms of machining, it performs well in the annealed state; however, tool wear increases significantly once hardened.

Cost-Effectiveness

Because it contains minimal nickel and no molybdenum, 410 is generally more economical than 304 or 316. It offers the best price-to-performance ratio for applications requiring high mechanical strength and basic rust protection.

Applications of 410 Stainless Steel

410 Stainless Steel / CA15 is commonly used in the following areas:

- Pumps and Valves: Pump shafts, valve stems, seats, internal trim, and valve bodies.

- Energy and Turbines: Gas/steam turbine blades, nozzles, wear rings, and fasteners.

- Mechanical Transmission: Shafts, couplings, gear blanks, and bushings.

- Industrial Tools: Shear blades, industrial knives, and medical/surgical instruments.

These applications typically require a combination of high load-bearing capacity, wear resistance, and moderate corrosion protection.

Comparison: 410 vs. 304 Stainless Steel

While 304 is the “universal” stainless steel, 410 is a “functional” high-strength alloy.

- Structure: 410 is martensitic (hardenable); 304 is austenitic (not hardenable by heat).

- Corrosion Resistance: 304 is superior due to higher chromium and nickel content.

- Strength & Hardness: 410 is much harder and stronger after tempering, making it better for wear-resistant parts.

- Magnetism: 410 is magnetic; 304 is generally non-magnetic.

Selection Tip: Use 304 for corrosion-heavy or welded structures. Use 410 for parts requiring high torque, hardness, or wear resistance.

Comparison: 410 vs. 316 Stainless Steel

316 is an upgraded version of 304 with molybdenum added for extreme environments.

- Corrosion Resistance: 316 is the standard for marine and chemical environments. 410 will rust in these conditions.

- Mechanical Properties: 316 is ductile and tough but lacks the extreme hardness of tempered 410.

- Cost: 316 is significantly more expensive due to nickel and molybdenum content.

Selection Tip: Use 316 for seawater or strong chemical exposure. Use 410/CA15 for mechanical components in milder media where cost and strength are priorities.

Does 410 Stainless Steel Rust?

410 contains about 12% chromium, allowing it to form a basic passive film. It resists rust well in dry air and fresh water.

However, 410 can still develop rust or pitting under the following conditions:

- Extreme Environments: Exposure to salt spray, high humidity, or strong acids.

- Improper Heat Treatment: Tempering between 450°C and 550°C causes “chromium depletion” at grain boundaries, significantly lowering corrosion resistance.

- Surface Contamination: Residual iron particles from sandblasting or lack of passivation.

Is 410 Stainless Steel Magnetic?

Yes, 410 stainless steel is strongly magnetic. As a martensitic steel, its crystal structure (body-centered cubic) is naturally ferromagnetic. This distinguishes it from the 300-series austenitic steels.

Being magnetic does not mean it is “fake” stainless steel. On the contrary, its magnetism is a functional benefit, allowing for Magnetic Particle Inspection (MPI) to detect surface defects during the casting process.

Conclusion and Recommendations

410 Stainless Steel (CA15) is an ideal solution for high-strength components operating in moderately corrosive environments. It serves as a cost-effective middle ground between carbon steel and expensive austenitic alloys like 316.

If you are evaluating 410/CA15 stainless steel castings for your pump, valve, or turbine projects, feel free to send your drawings to our engineering team. We can provide professional material selection, heat treatment advice, and customized casting solutions.