Introduction

Note on Terminology:

In this article, “sand casting” refers specifically to a casting process, while terms like “steel casting”, “iron casting”, and “aluminum casting” often refer to both the material used and the associated casting techniques. For simplicity and clarity, we’ll compare these four casting types based on their common industrial usage.

Selecting the right casting process can significantly impact your product quality, cost efficiency, and delivery timelines. With various techniques available — including sand casting, steel casting, iron casting, and aluminum casting — it’s important to understand their differences to make the best decision for your project.

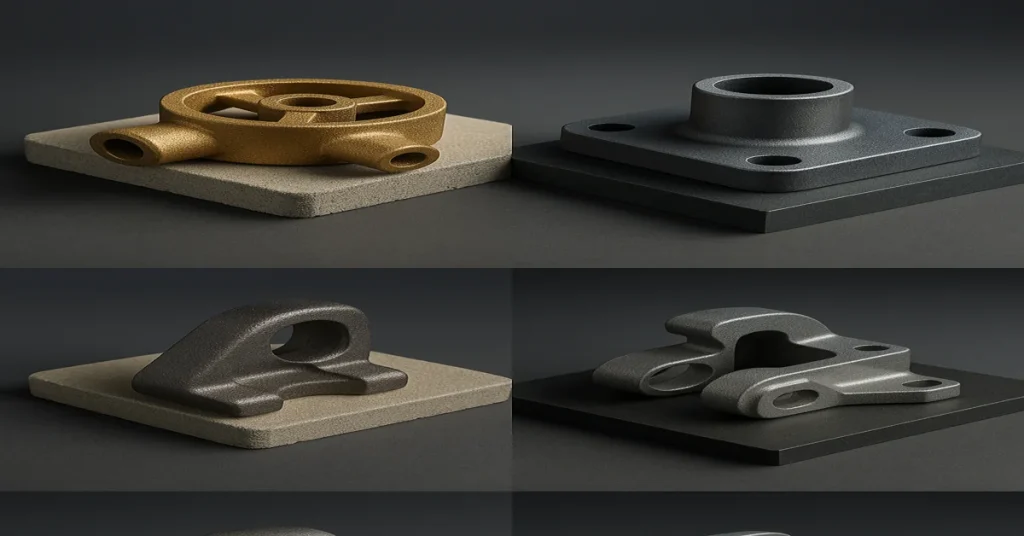

1. Sand Casting

Sand casting is one of the oldest and most adaptable casting processes. It uses sand molds to form parts and is especially cost-effective for large components or small production runs.

Advantages

- Ideal for prototyping and custom jobs

- Works with a wide variety of metals

- Low tooling and mold costs

Limitations

- Lower surface finish and dimensional accuracy

- Requires secondary machining for precision

Common Applications

Machine bases, engine blocks, pump housings.

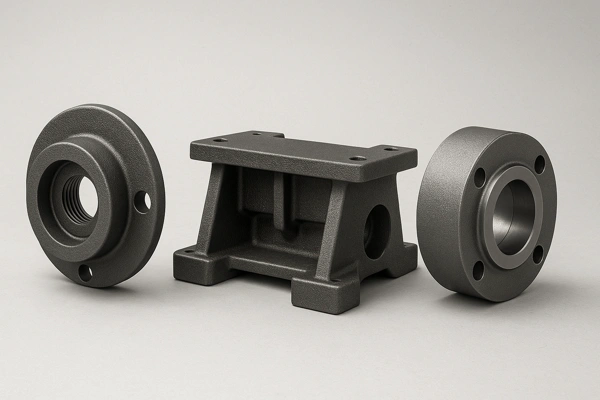

2. Steel Casting

Known for its strength and durability, steel casting is often used in demanding environments like mining, construction, and heavy equipment manufacturing.

Advantages

- Superior mechanical strength

- Excellent resistance to wear and impact

Limitations

- Higher production costs

- Requires tight temperature control and expert handling

Common Applications

Valves, gears, structural tools, and custom parts requiring high strength.

3. Iron Casting

Iron casting, particularly ductile and gray iron, offers great wear resistance and vibration damping. It’s a go-to option for high-volume production where strength and cost control are key.

Advantages

- Good fluidity for complex shapes

- Excellent vibration absorption

- Cost-effective for large quantities

Limitations

- Brittle compared to steel

- Lower tensile strength

Common Applications

Automotive parts, brake drums, manhole covers.

4. Aluminum Casting

Aluminum casting is prized for its light weight and resistance to corrosion. It’s especially common in the automotive and electronics sectors.

Advantages

- Lightweight, excellent for weight-sensitive parts

- Good thermal and electrical conductivity

- Fast production cycles, especially with die casting

Limitations

- Lower strength than steel or iron

- Not suitable for heavy-load components

Common Applications

Brackets, housings, enclosures, and electronic components.

🔍 Comparison Table of Casting Methods

| Casting Method | Cost | Strength | Precision | Best Applications |

|---|---|---|---|---|

| Fundição em areia | ★★ | ★★★ | ★ | Prototypes, machine bases, large parts |

| Fundição de aço | ★ | ★★★★★ | ★★★ | Mining tools, valves, heavy-duty parts |

| Iron Casting | ★★ | ★★★ | ★★ | Auto parts, manhole covers, machine frames |

| Fundição de alumínio | ★★★★ | ★★ | ★★★★ | Brackets, electronics, lightweight mechanical parts |

Conclusion

Each casting method has unique advantages depending on your specific needs. For instance, if you’re producing high-strength parts for mining equipment, fundição de aço may be the way to go. On the other hand, if weight and corrosion resistance matter most, fundição de alumínio could be your best fit.

By understanding the properties and limitations of each process, you can better match your casting choice to your product’s technical requirements and production goals.

👉 Learn more about our Fundição de aço, Iron Castinge Fundição de alumínio capabilities.